Engineers atRutgers Universityhave developed a technique for 3D printing large, complicated parts for a tenth of the price of existing approaches. The team published their findings in the journalAdditive Manufacturing.

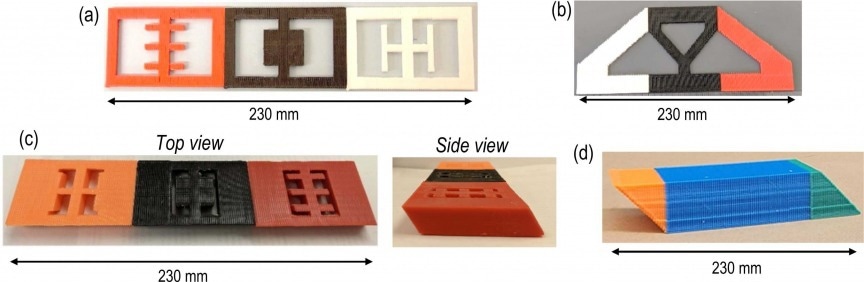

Parts printed with the MF3 prototype using a 0.4 mm diameter nozzle. Image Credit: Rutgers The State University of New Jersey

Parts printed with the MF3 prototype using a 0.4 mm diameter nozzle. Image Credit: Rutgers The State University of New Jersey

We have more tests to run to understand the strength and geometric potential of the parts we can make, but as long as those elements are there, we believe this could be a game changer for the industry.

杰里米·克莱曼(Jeremy Cleeman),罗格斯工程学院的学习首席作者兼研究生研究员

The brand-new technique, known as Multiplexed Fused Filament Fabrication (MF3), employs a single gantry — the movable component of a 3D printer — to print a single item or many pieces concurrently.

研究人员能够通过对其原型进行编程以进行有效的模式,并使用许多小喷嘴来沉积熔融材料而不是单个大型喷嘴,从而增加打印分辨率和大小,并明显减少打印时间,就像常规打印一样。

Cleeman added, “MF3将改变热塑料打印的方式。”

克莱曼说,他的小组已在美国提交了专利申请,以实现其新技术。

对于3D打印业务来说,吞吐量解决方案或3D打印机存放材料与最终产出质量的速度是一个问题。

Although larger-diameter nozzles produce more ridges and curves that must be smoothed down afterward, they are faster than smaller ones. This results in higher post-production expenditures.

Smaller nozzles, however, deposit material with a higher degree of precision, but existing techniques using standard software are too slow to be economically viable.

At the heart of MF3’s innovation is its software. A software tool known as a slicer, which translates an item into the virtual “slices” or layers, is used by engineers to configure a 3D printer.

为了使龙门臂尽可能高效地操作,Rutgers研究人员创建了切片器软件,该软件计算出何时打开和关闭喷嘴。研究人员在他们的研究中指出,MF3的新“工具路线策略”可以使用单个打印机“同时打印多个,几何不同的,几何,无连体尺寸的部分”。

克莱曼说,他认为这项技术可以带来许多优势。使预期采用更简单的一个因素是,MF3中使用的硬件可以从架子上购买,而无需更改。

另外,MF3打印机具有内置的弹性,并且由于喷嘴可以单独打开和关闭而易于昂贵的停机时间。例如,典型的打印机必须在喷嘴故障时停止打印。同一手臂上的另一个喷嘴可以接管MF3打印中破裂的喷嘴的角色。

Rajiv Malhotra,Alex Bogut,Brijesh Mygrolia,Adeline Ripberger,Qingze Zou和路易斯维尔大学的研究人员是研究的合着者。

Journal Reference:

Cleeman, J.,等。(2022)融合细丝制造的可扩展,柔性和弹性并行化:材料挤压添加剂制造中的特有折衷方案。添加剂制造。doi:10.1016/j.addma.2022.102926.

来源:https://www.rutgers.edu/