May 23 2022Reviewed by Alex Smith

Metal can be formed into various designs in a variety of ways, such as casting, machining, rolling, and forging. These mechanisms have an impact on the sizes and shapes of the small crystalline grains that comprise the bulk metal, whether it is steel, aluminum, or another commonly used metal or alloy.

研究人员首次描述了如何形成最固体金属的微晶晶粒。他们说,从理论上讲,了解这一过程可能会导致产生更强大,更较轻的金属,例如铝,钢和钛。图片来源:由研究人员提供。

麻省理工学院现在,科学家已经能够检查当这些晶体在最小的尺度上发生强烈变形期间形成这些晶体时会发生什么,直至几纳米。最近的发现可能会导致更好的处理方法,从而产生良好,更持续的特性,例如硬度和力量。

前麻省理工学院博士后Ahmed Tiamiyu(目前是卡尔加里大学的助理教授),Christopher Schuh,Keith Nelson和James Lebeau和James Lebeau(麻省理工学院教授),前学生Edward Pang和现任学生XI Chen出版了这些发现,并通过全面的分析来启用这些发现。来自强大成像系统套件的图像自然材料亚博网站下载。

In the process of making a metal, you are endowing it with a certain structure, and that structure will dictate its properties in service。

Christopher Schuh, Danae and Vasilis Salapatas Professor, Metallurgy, Massachusetts Institute of Technology

The tinier the grain size, in fact, the stronger the resulting metal. Striving to enhance strength and durability by reducing grain size “在过去的80年中,” he says.

Metallurgists have long-used empirically evolved methods to minimize the sizes of the grains in a portion of solid metal, usually by imparting various types of strain by disintegrating it in some way. However, it is difficult to make these grains narrower.

The basic mechanism is recrystallization, which involves deforming and heating the metal. This results in numerous minor flaws throughout the piece, which is “highly disordered and all over the place,” says Schuh.

当金属弯曲并加热时,所有这些缺陷都可以自发产生新晶体的核。“You go from this messy soup of defects to freshly new nucleated crystals. And because they’re freshly nucleated, they start very small,” resulting in a structure with much smaller grains, Schuh explains.

他声称当前的工作是例外的,因为它标识了该过程以极高的速度和最细微的尺度出现的方式。虽然传统的金属形成操作(例如锻造或纸滚动)可能相对较快,但这项新研究研究了“several orders of magnitude faster,” Schuh says.

We use a laser to launch metal particles at supersonic speeds. To say it happens in the blink of an eye would be an incredible understatement because you could do thousands of these in the blink of an eye。

Christopher Schuh, Danae and Vasilis Salapatas Professor, Metallurgy, Massachusetts Institute of Technology

他声称这样一个快速的过程不仅是实验室的迷恋。“There are industrial processes where things do happen at that speed。”

这些包括高速加工,高能金属粉末铣削和冷喷涂工艺。在研究中,“we’ve tried to understand that recrystallization process under those very extreme rates, and because the rates are so high, no one has been able to dig in there and look systematically at that process before,” he says.

Using a laser-based system to shoot 10-micrometer particles at a surface, Tiamiyu, who conducted the experiments, “could shoot these particles one at a time, and measure how fast they are going and how hard they hit,” Schuh says.

他使用MIT.NANO设施的一系列高级显微镜技术与显微镜专家合作,他将以不断变化的速率拍摄颗粒,然后将它们切开以研究晶粒结构如何改变,以降低到纳米尺度。yabo214

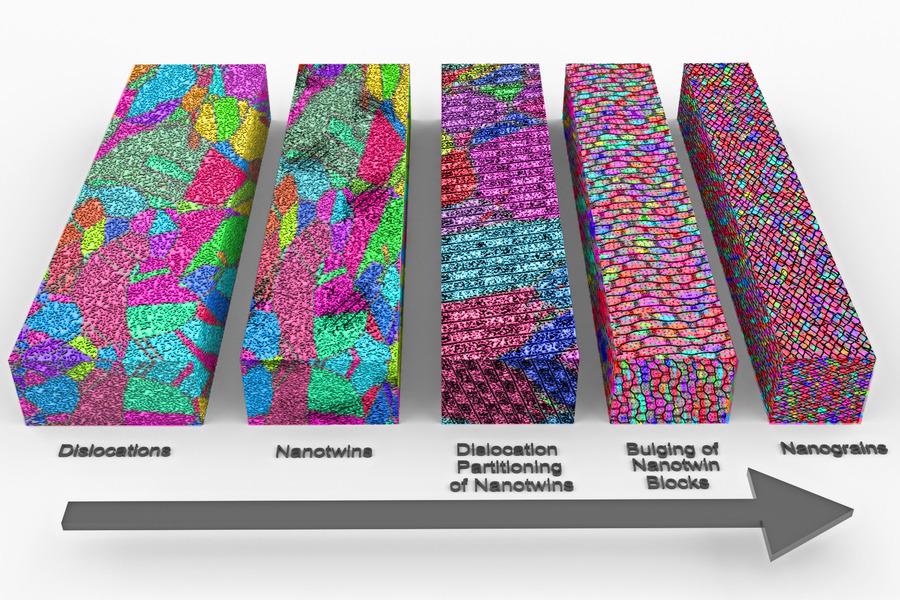

The outcome was the identification of a “novel pathway” for grain formation down to the nanoscale scale, according to Schuh. The new approach, termed nano-twinning assisted recrystallization, is a version of twinning, a well-known occurrence in metals in which a portion of the crystalline structure switches its orientation.

It is a “mirror symmetry flip, and you end up getting these stripey patterns where the metal flips its orientation and flips back again, like a herringbone pattern,” he says. The researchers discovered that the faster these collisions occurred, the more this process occurred, resulting in smaller grains as the nanoscale “twins” split up into fresh crystal grains.

The technique of blasting the surface with these small particles at high speed could boost the metal’s strength by tenfold in their copper tests. “这不是属性的微小变化,” Schuh says, and this is not surprising because it is an expansion of the known effect of hardening caused by conventional forging hammer strikes. “This is sort of a hyper-forging type of phenomenon that we’re talking about。”

Researchers were able to use a variety of imaging and measurement techniques on the identical particles and impact locations in the trials.

So, we end up getting a multimodal view. We get different lenses on the same exact region and material, and when you put all that together, you have just a richness of quantitative detail about what’s going on that a single technique alone wouldn’t provide。

Christopher Schuh, Danae and Vasilis Salapatas Professor, Metallurgy, Massachusetts Institute of Technology

根据Tiamiyu的说法,最新的研究可以立即应用于现实世界中的金属制造,因为它们有助于所需的变形程度,发生变形的速度以及用于任何给定特定的特定金属或加工技术的最大效果的温度。研究人员应该能够在其他情况下使用他们从实验中创建的图表。

“They’re not just hypothetical lines,” Tiamiyu says. For any given metal or alloy, “如果您要确定纳米属是否会形成,如果您有参数,则只需将其插入其中”他们建立的公式,结果应说明在不同的影响速度和温度下可以预测哪种晶粒结构。

The US Department of Energy, the Office of Naval Research, and the Natural Sciences and Engineering Research Council of Canada all contributed to the study.

期刊参考:

Tiamiyu,A。A.,等。((2022) Nanotwinning-assisted dynamic recrystallization at high strains and strain rates.自然材料亚博网站下载。doi.org/10.1038/S41563-022-01250-0。

Source:https://web.mit.edu/