印度石油和能源研究大学和萨勒诺大学的一组研究人员发表了一篇论文,调查了用氧化石墨烯官能化碳纤维增强复合材料(CFRP)的效果。在期刊上写作Polymers, their research has been published this week.

Study:An Overview on Carbon Fiber-Reinforced Epoxy Composites: Effect of Graphene Oxide Incorporation on Composites Performance. Image Credit: Dhujmontra/Shutterstock.com

Carbon Fiber-Reinforced Composites

CFRPs have found application in multiple industries, including the marine and aerospace industries. These materials possess excellent tensile strength, but they are hindered by drawbacks such as brittleness and weak interface adhesions, which can lead to delamination and catastrophic failure.

One strategy to overcome the drawbacks of these composite materials is to incorporate nanostructured carbon forms. Several studies have explored using these materials to improve the mechanical performance of these composite materials and introduce functional properties such as self-healing, self-sensing, and de-icing, as well as to save energy during manufacture.

Carbon Nanostructured Forms

Incorporating different carbon nanostructured forms into composites can introduce different functional properties and improvements in mechanical properties.

Multi-wall carbon nanotubes, for instance, can be incorporated to give the composites improved electrical conductivity, with the manufacturing process influencing the value of electrical conductivity. Incorporating graphene-based nanoparticles can further improve some of the functional properties depending on thermal management and can reduce the humidity content of epoxy resin-based composites.

There has been significant research focus on obtaining single-layered graphene, but thus far, no high-performance materials with superior electrical conductivity and related functional properties have been developed. Graphene layers tend to reassemble during manufacturing, hindering the development of defect-free materials. Functionalization procedures are needed to avoid reassembly, further complicating the process and presenting challenges such as reduced electronic properties.

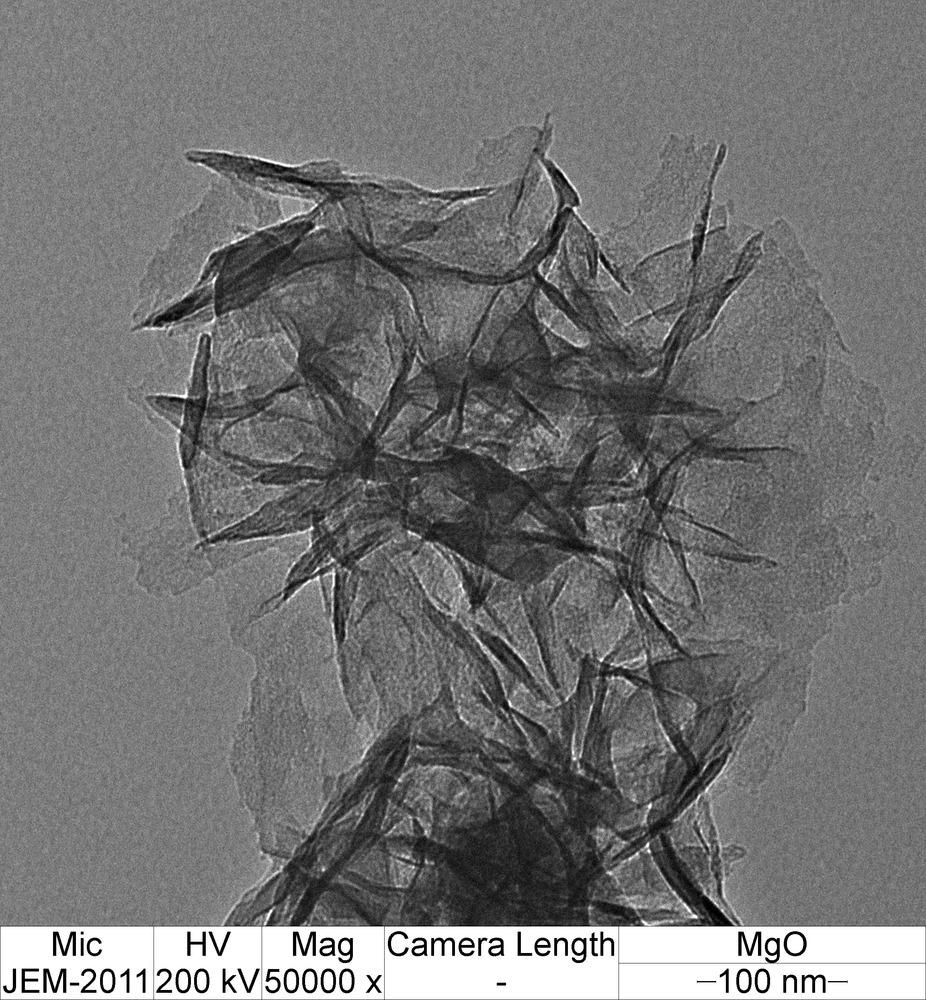

Graphene oxide nanosheets, which consist of stacked graphene layers, can address these issues. Dispersing graphene oxide nanoparticles in the polymeric matrix can also improve the adhesion between carbon fibers and the epoxy matrix during the process of impregnation. The presence of polar functional groups in graphene nanoparticles provides strong interactions with the epoxy matrix. Strong interactions with the carbon fibers are facilitated by the core structure of the nanoparticles.

几篇论文报告了石墨烯纳米颗粒为树脂提供官能团的能力,而另一些论文则报道了聚合物和增强碳纤维之间的粘附。yabo214改善聚合物和碳纤维之间的粘附在改善整体复合材料的性能方面起着关键作用。

The Study

The authors have reviewed recent developments and research into improving the properties and performance of CFRPs with graphene oxide nanoparticles. Ninety-one relevant papers in the current literature have been analyzed and reviewed in the current study.

Incorporating graphene oxide nanosheets improves the viscoelastic, thermal, mechanical, and electrical properties of these materials. The study has covered the effect of the involvement of functional groups in the covalent functionalization of these composite materials. A key effect of graphene oxide is the opening of reaction sites in both the fiber surface and polymer matrix.

The authors have noted that different functional groups have different effects on the composites. Hydroxyl groups provide fibers with a void-containing and globular dendritic surface topology, whereas carboxyl groups have the effect of oxidizing the same surfaces. Both groups provide the fibers with open spaces to facilitate stronger interlocking with the polymer matrix.

来自AZOM的更多内容:拉曼光谱在工业过程中的关键作用

Several functionalization approaches can be employed to improve interfacial adhesion. The use of silane coupling agents is particularly attractive because they produce hydroxyl, carboxyl, and amine groups on both the edges and the surfaces of the materials.

不同的制备过程可用于改善聚合物基质中的氧化石墨烯分散体。其中,三卷研磨产生更均匀的色散(其他技术是超声波和剪切混合。)这是因为该方法的易于处理和缺乏其他方法所需的其他溶剂。但是,作者指出,达到均匀的氧化石墨烯纳米颗粒分散剂仍然存在挑战。与氧化石墨烯/基质修饰相比,纤维表面修饰的兼容性更好。

Additionally, the review has investigated current and future applications of graphene oxide-modified composites. Industries which make use of these materials include the aerospace industry, automobile industry, military, and civil engineering sectors. The automobile industry has applied them in engine parts, ballistic systems such as next-generation body armor, and as cables for suspension bridges. Composites have been used in research into energy storage devices and sensing capabilities.

Further Reading

Sharma, H et al. (2022)An Overview on Carbon Fiber-Reinforced Epoxy Composites: Effect of Graphene Oxide Incorporation on Composites Performance[online]Polymers14(8) 1548 | mdpi.com. Available at:https://www.mdpi.com/2073-4360/14/8/1548

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of theTerms and conditionsof use of this website.