Researchers who assisted in pioneering the utilization of enzymes to break down plastic have taken a significant next step in engineering nature-based solutions to the plastics crisis worldwide.

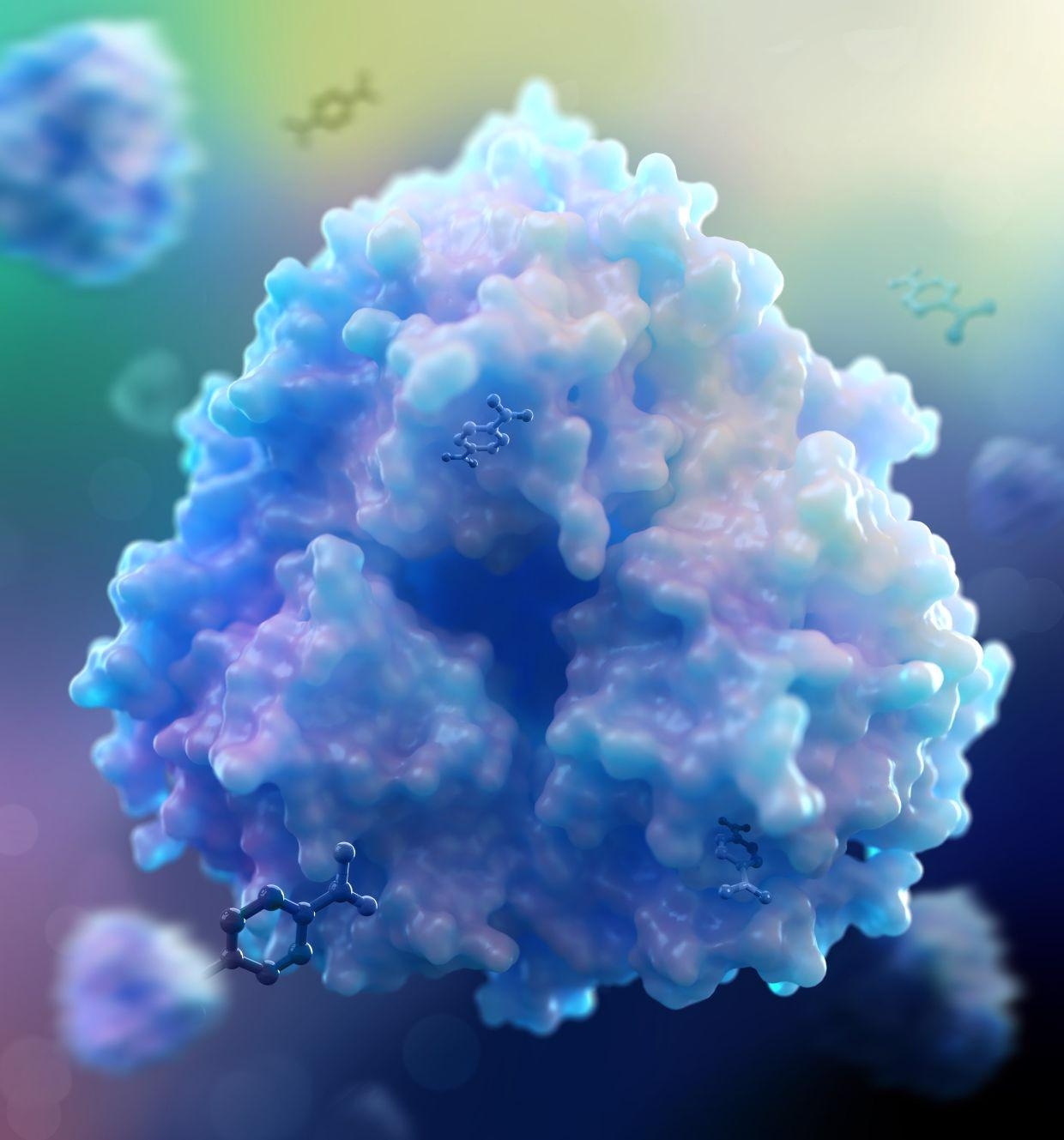

The TPADO enzyme. Image Credit: Rita Clare, Montana State University.

The TPADO enzyme. Image Credit: Rita Clare, Montana State University.

They have identified an enzyme that has the extraordinary capacity to help disintegrate terephthalate (TPA), one of the chemical building blocks of polyethylene terephthalate (PET) plastic, which is employed to create clothing, single-use drinks bottles and carpets.

The study was co-led by Professor John McGeehan from theUniversity of Portsmouthand Professor Jen DuBois, Montana State University. Details of the study have been reported inThe Proceedings of the National Academy of Sciences(PNAS). In 2018, Professor John McGeehan led the international team that designed a natural enzyme capable of breaking down PET plastic.

The enzymes (MHETase and PETase) disintegrate the PET polymer into the chemical building blocks TPA and ethylene glycol (EG). This new study illustrates the subsequent steps, particularly for handling TPA.

While EG is a chemical with many uses – it’s part of the antifreeze you put into your car, for example – TPA does not have many uses outside of PET, nor is it something that most bacteria can even digest. However, the Portsmouth team revealed that an enzyme from PET-consuming bacteria recognises TPA like a hand in a glove.

Jen DuBois, Professor and Study Co-Lead, Montana State University

“Our group at MSU then demonstrated that this enzyme, called TPADO, breaks down TPA and pretty much only TPA, with amazing efficiency,”DuBois added.

With over 400 million tons of plastic waste generated annually, the vast majority of which gets dumped in landfills, it is anticipated this study will pave the way to advance bacterial enzymes, like TPADO. This will help manage the crisis of plastic pollution and build biological systems that can turn waste plastic into beneficial products.

The last few years have seen incredible advances in the engineering of enzymes to break down PET plastic into its building blocks. This work goes a stage further and looks at the first enzyme in a cascade that can deconstruct those building blocks into simpler molecules. These can then be utilised by bacteria to generate sustainable chemicals and materials, essential making valuable products out of plastic waste.

Professor John McGeehan, Study Co-Lead and Director of Centre for Enzyme Innovation, University of Portsmouth

“Using powerful X-ray at the Diamond Light Source, we were able to generate a detailed 3D structure of the TPADO enzyme, revealing how it performs this crucial reaction. This provides researchers with a blueprint for engineering faster and more efficient versions of this complex enzyme,”Professor McGeehan added.

The research was carried out as part of the BOTTLE Consortium, an international partnership between the UK and the United States, uniting scientists from across a broad range of scientific domains to handle the recycling and upcycling of plastics.

Journal Reference:

Kincannon, W. M.,et al. (2022) Biochemical and structural characterization of an aromatic ring–hydroxylating dioxygenase for terephthalic acid catabolism.The Proceedings of the National Academy of Sciences.doi.org/10.1073/pnas.2121426119.

Source:https://www.port.ac.uk