FromAsynt2022年2月1日Reviewed by Maria Osipova

Asynt reports how the Process Intensification Group, within the School of Engineering at Newcastle University, UK is using the MultiCell-PLUS High-Pressure Reactor as part of their program of ongoing research to create a new environmentally friendly generation of catalysts for production of biorenewable chemicals.

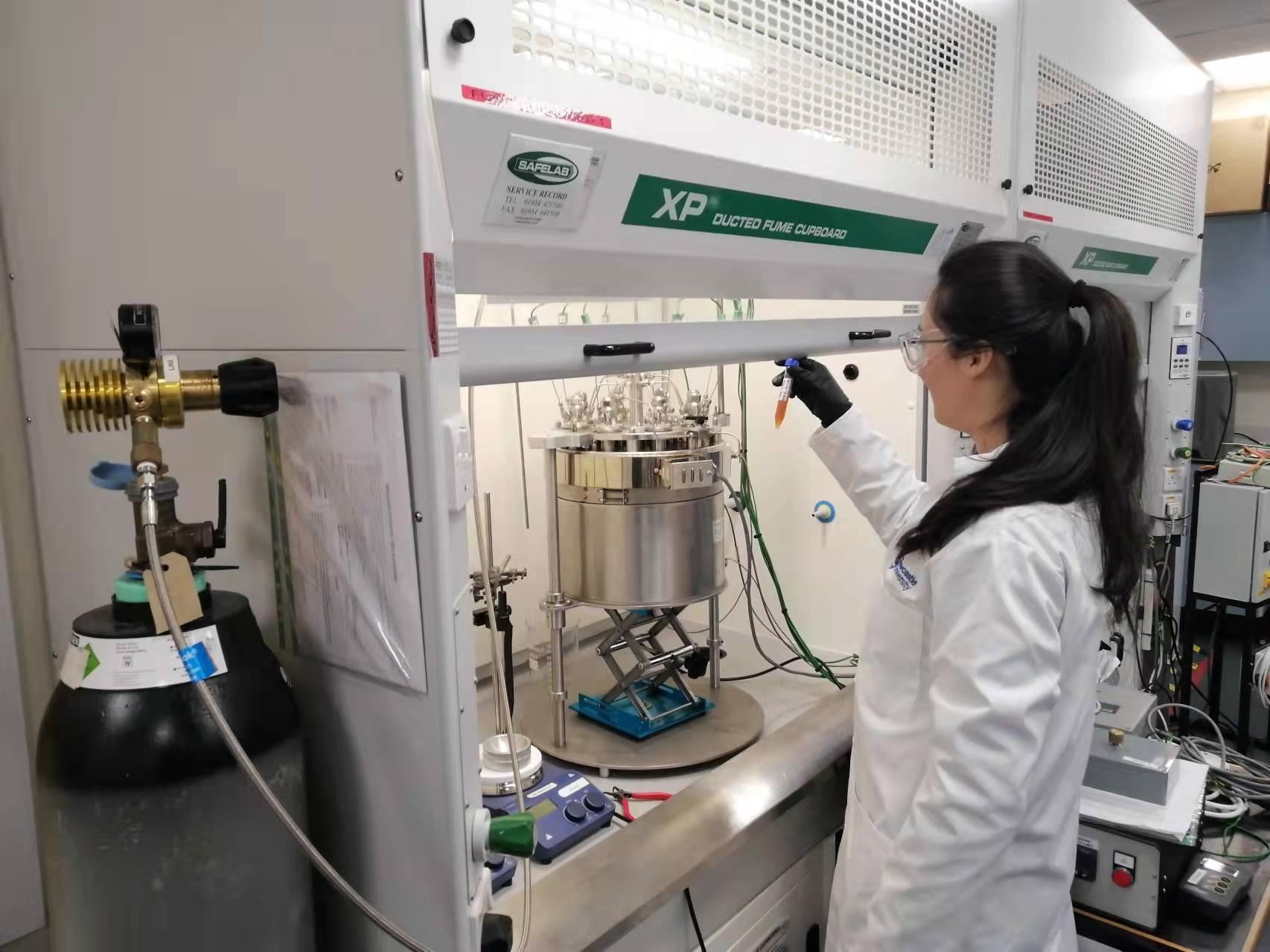

Dr Zongyuan Zhu from the Process Intensification Group, University of Newcastle, UK. Image Credit: Asynt

Dr Zongyuan Zhu from the Process Intensification Group, University of Newcastle, UK. Image Credit: Asynt

许多工业过程依赖于含有昂贵的珍贵和金属或来自冲突地区的金属的催化剂。该过程强化组的一个关键目标是开发负担得起的,危险的催化剂,以实现与当前可用的催化剂的功能和性能相似的功能和性能,使合成简单易于扩展。

该过程强化小组的讲师Fernando RussoAbegão博士说“为了开发新一代的催化剂,我们需要能够在高压和温度下筛选大量样品。过去,我们在实验室中只有孤立的高压灭菌。这些不是筛查的理想选择,因为它们需要大量的催化剂进行测试,而且我们一次只能进行一种反应。为了有效,我们需要一种可以提供快速周转的工具设置,使我们能够快速测试,合理化和识别最佳的催化剂配方。”

可持续过程技术的读者Kamelia Boodhoo博士补充说“For screening of heterogeneous catalysts, mass transfer can play a big role in the process. We wanted to ensure that we selected a high-pressure reactor system that was well stirred to keep the particles in suspension at all times, reducing mass transfer limitations. By doing this, it enabled us to screen the catalyst intrinsic activity, rather than having the results masked by mass transfer limitations. For some of the reactions we investigate, accurate temperature control is also very important – a few degrees under the desired temperature and the reaction won’t progress fast enough, a few degrees above, and we experience unwanted side reactions. It is therefore important to stay within the correct temperature ranges to ensure optimal catalyst and reaction performance. We looked at various commercially available high-pressure reactors and chose the MultiCell-PLUS system from Asynt as it incorporated parallel agitated reactors with automatic temperature and pressure control. Using this versatile, high-performance system we have already successfully developed a new generation of ‘greener’ catalysts for dehydration of C5 and C6 sugars into furans. Looking to the future, our plan is also to use the MultiCell-PLUS for screening of solvents and process conditions”.

The Multicell-PLUS was developed by Asynt to provide scientists with a flexible and customisable device for high throughput screening of chemical reactions under high pressure. The reactor allows users to set up a multitude of experimental conditions in each of its 8 reaction cells, ideal for optimisation and screening investigations. Manufactured from 316 stainless steel, the Multicell-PLUS standard unit operates up to 50 barg and up to 200 ºC. For more demanding and corrosive chemistries, there are options for alternative alloys and for increased operational conditions up to 200 barg and 300 ºC. Motor-driven magnetically coupled overhead stirring is also offered as an option for reactions involving particulate suspensions or viscous reaction mixtures. With its own safety-locking mechanism and adjustable support lifting platform, the Multicell-PLUS high-pressure reactor sets a new benchmark for operator safety, all-round accessibility, and ease-of-use.

For further information on the MultiCell-PLUS please visit:https://www.asynt.com/product/multicell-plus/

Source:http://www.asynt.com/