希腊和法国的研究人员在其最新文章中发表在《杂志》上GydF4y2Ba能量GydF4y2Ba,研究了转子杆形状的影响,以提高单相感应电动机的效率。GydF4y2Ba

学习:GydF4y2BaEffect of Rotor Bars Shape on the Single-Phase Induction Motors Performance: An Analysis toward Their Efficiency Improvement。图片来源:Yura Borson/Shutterstock.comGydF4y2Ba

Importance of Motor Efficiency and the Latest Study

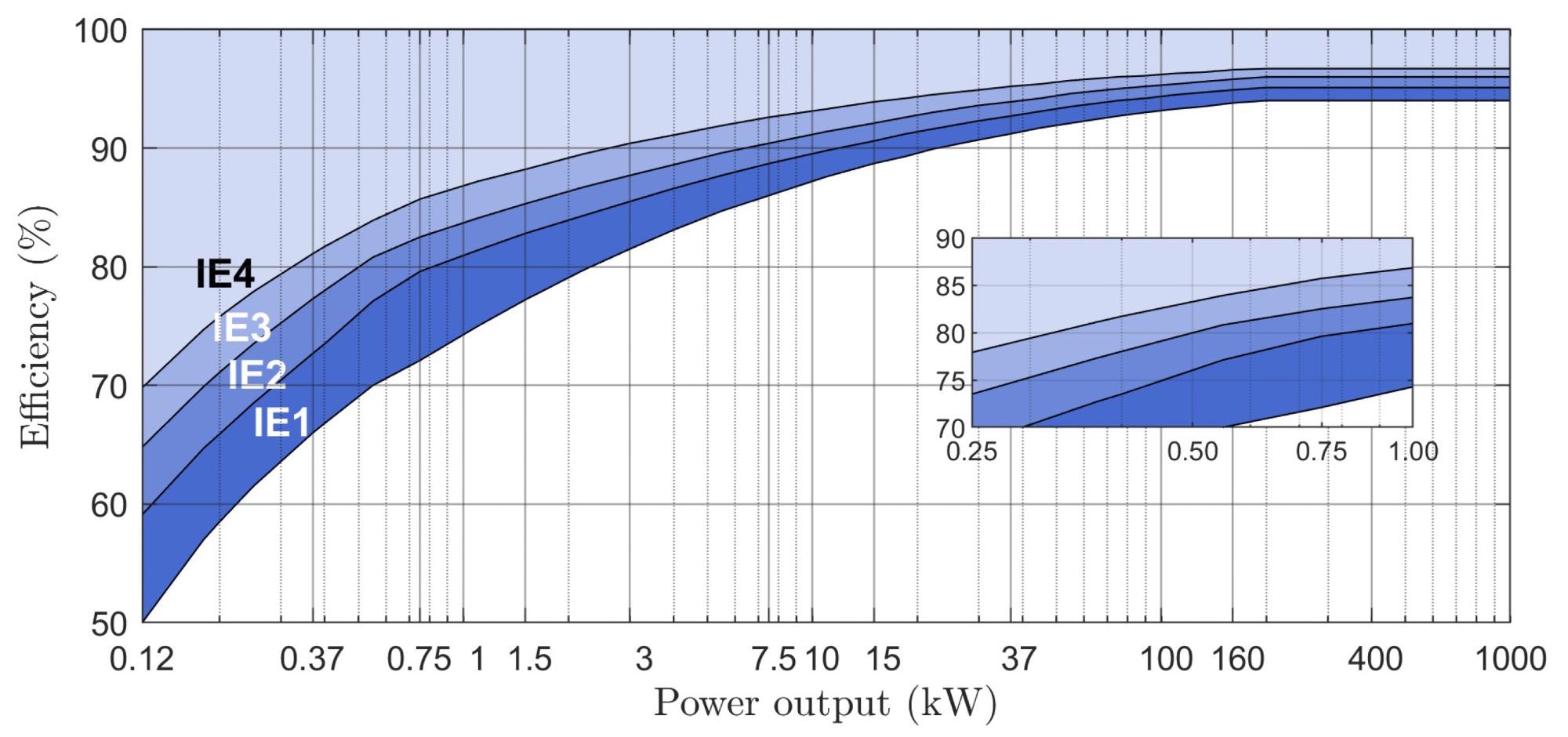

在全球范围内,已经建立了对线路操作电动机有效性的强制性要求。紧凑的单相感应电动机(SPIM)将不会在有效性和效率方面幸免,因为将不迟于2023年7月实施新的限制。结果,将需要超过电容器运行的效率以超过(现在)正常值并符合IE3(即高级)性能类的标准。不考虑转子杆形式对SPIM性能和起始功能的影响。本文通过调查了带有八种不同条形的转子松鼠笼布局,涵盖了该区域。GydF4y2Ba

四极IMS的国际效率课程为50 Hz。图片来源:Chasiotis,I.D等人,能量GydF4y2Ba

什么是单相感应电动机?GydF4y2Ba

单相感应电动机(SPIMS)是全球电动机行业中很大一部分的一部分,这是由于它们在各种产品中的广泛使用(例如,切割工具,加压清洁技术,旋转皮带,最新有效的洗涤机,商业研磨机,商业磨床,,商业磨床,,商业研磨机,,食品存储设施,食品搅拌机,微波炉,调理单元,热循环泵,风扇,离心泵等)。它们的额定输出功率从几千瓦到几百千瓦,并且根据用于使它们自动开机的机制提供各种设计。GydF4y2Ba

单相感应电动机的配置GydF4y2Ba

They are available in five varieties: (a) split-phase, (b) shaded poles, (c) capacitor-start/induction-run, (d) capacitor-start/capacitor-run, and (e) capacitor-run SPIMs. Because the transmitted single-phase current generates only a pulsing electromagnetic field, the beginning mechanism is required.

SPIM与感应电动机的比较GydF4y2Ba

该电动机的结构与三相松鼠式感应电动机(IM)完全相同。基本区别在于定子的主要和补充绕组的配置。这些线圈是90个电度的垂直移相。在电动机的启动和操作操作期间,固定电容器串联与次级线圈链接。GydF4y2Ba

刺的结构和转子杆设计GydF4y2Ba

SPIM的定子和转子芯由电金属的薄层组成。转子的松鼠笼由通过铸件制造的合金制造。由于其价格便宜的成本,铝合金更常用于制造微小的刺激物,并且可以在酒吧设计方面更大。GydF4y2Ba

为了确定哪种优势是电动机的性能参数,已经为转子杆设计提供了半关闭,封闭或开放插槽的几种配置。根据国家电气制造商协会的指南,将栏设计分为四类(设计类)。这些中的每一个都为电动机提供了独特的扭矩 - 滑行曲线,并对机器的运行效率和发射功能产生了重大影响。GydF4y2Ba

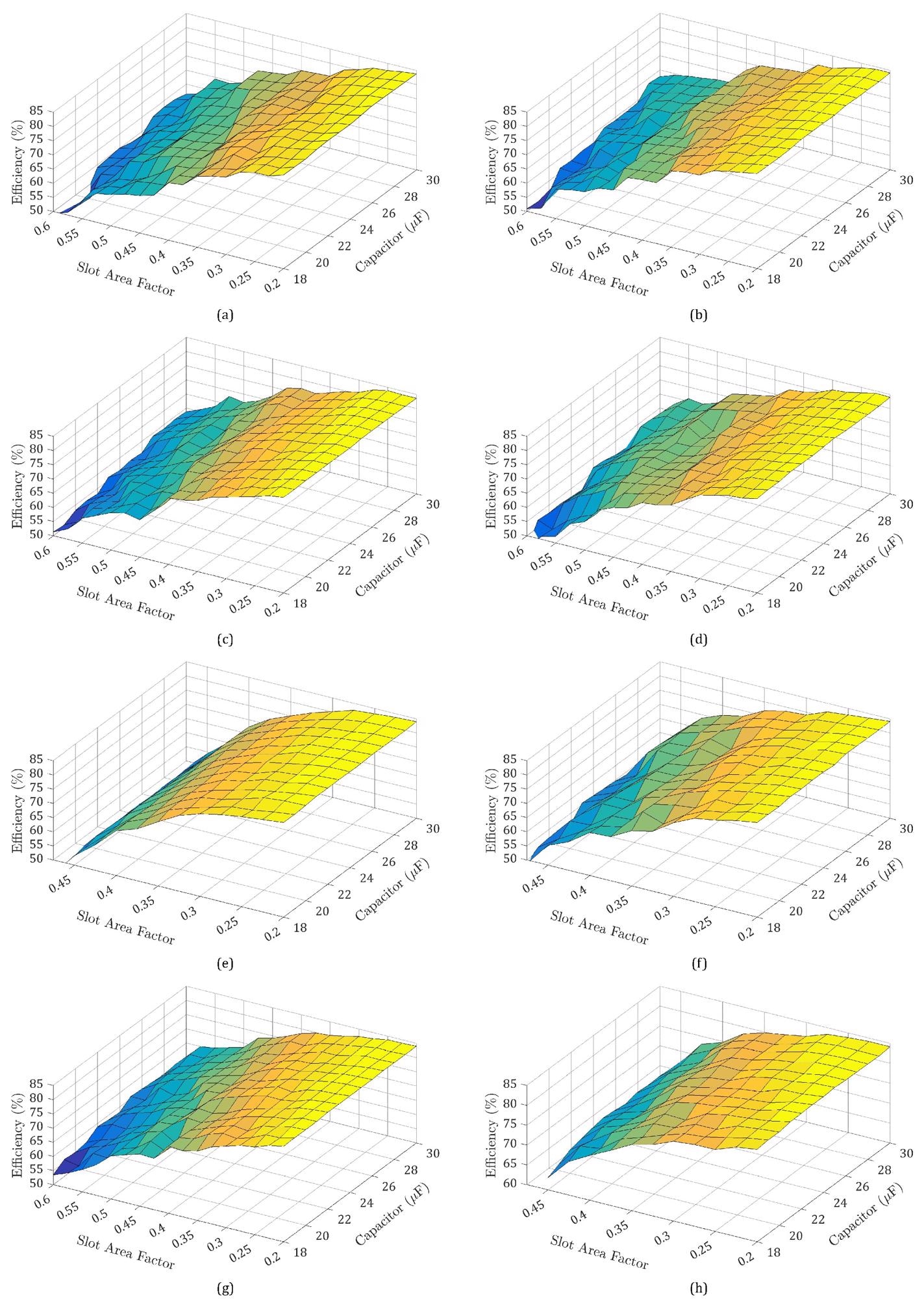

Impact of Crun和kGydF4y2Ba酒吧GydF4y2Ba关于用转子松鼠笼杆的刺激效率:(GydF4y2BaAGydF4y2Ba)trapezoidal, (bGydF4y2Ba) 椭圆形, (GydF4y2BaCGydF4y2Ba)pent,((GydF4y2BadGydF4y2Ba)多边形((GydF4y2BaeGydF4y2Ba)round, (FGydF4y2Ba)drop, (GGydF4y2Ba)rectangular, and (HGydF4y2Ba)四边形形状。图片来源:Chasiotis,I.D等人,能量GydF4y2Ba

Traditional Methods for Improving Efficiency

To date, research studies have focused on the emergence of more precise magnetic and thermal models for better assessment of the motor's electromagnetic and thermal behavior, the optimized rotor squirrel cage configuration, the appropriate choice of the rotor bars/stator slots conjunction, and the establishment of innovative casting processes as well as novel materials for cores and squirrel cags.

Because the majority of the aforementioned solutions are not easily adaptable to large-scale production, it is critical to have design techniques that cause minor alterations to the pre-existing SPIMs manufacturing stage.

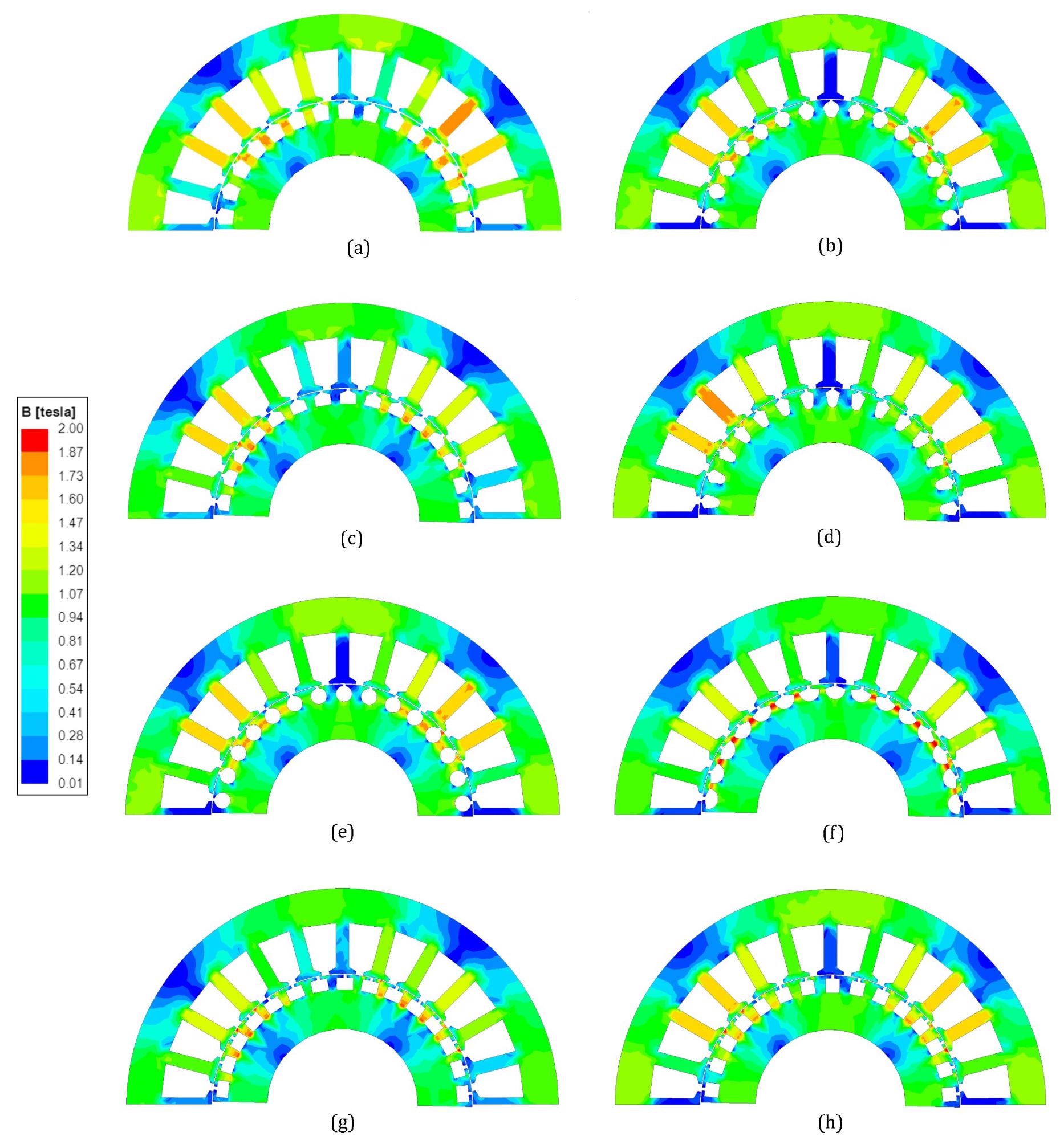

在SPIM的标称操作下,视图(½)部分和磁通量密度分布GydF4y2Barun=18μF和转子条:(GydF4y2BaAGydF4y2Ba)trapezoidal, (bGydF4y2Ba) 椭圆形, (GydF4y2BaCGydF4y2Ba)pent,((GydF4y2BadGydF4y2Ba)多边形((GydF4y2BaeGydF4y2Ba)round, (FGydF4y2Ba)drop, (GGydF4y2Ba)rectangular, and (HGydF4y2Ba)四边形形状。图片来源:Chasiotis,I.D等人,能量GydF4y2Ba

Research Findings

The influence of the rotor bar shape on the efficiency of the capacitor-run SPIM was examined and given in the study. The results showed that the design of the bar had a significant impact on the particular performance parameter. The gap between the lowest and maximal efficiency values of the best-performing SPIMs was 0.42 percent.

给定电容的最低效率和最大效率值之间的差异范围为0.31%至0.98%。有人指出,条形对各种操作特征有重大影响,例如开始电流,故障扭矩,电流偏移倾斜度,电磁饱和度等。由于对获得的SPIM的定量评估和结果的讨论,形成了有益的结论。GydF4y2Ba

总而言之,该研究阐明了具有提高效率的电容器运行的尖峰的阐明,同时还解决了诸如接触性对转子欧姆损失的影响以及电容对电动机磁化电感的影响。GydF4y2Ba

Further Reading

Chasiotis,I.D。;Karnavas,Y.L。;Scuiller,F。转子条形对单相感应电动机性能的影响:分析其效率提高。能量2022. 15(3)。717.可用:GydF4y2BaHttps://www.mdpi.com/1996-1073/15/3/717/htm

免责声明:此处表达的观点是以其私人身份表达的作者的观点,不一定代表AZOM.com的观点有限的T/A Azonetwork本网站的所有者和运营商。此免责声明构成了GydF4y2Ba条款和条件GydF4y2Baof use of this website.