A new breakthrough in printing metal using additive manufacturing with periodic layer rotation is explored in the journal亚博网站下载。Unlike traditional machining methodologies, additive manufacturing (AM) in the metal production process has the privilege of manufacturing complex shapes and allows customizable production.

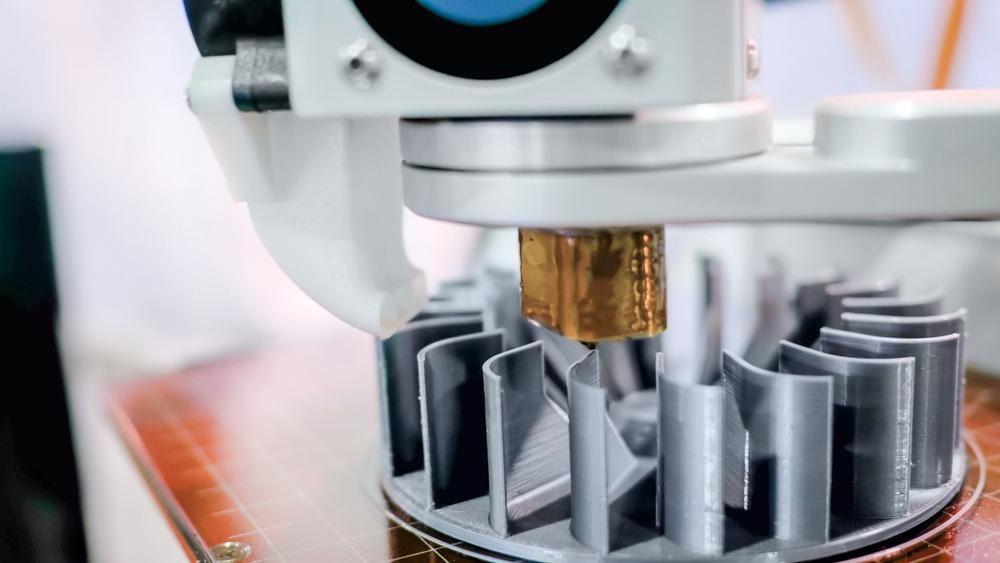

学习:A Study on the Mechanical Properties of an Automobile Part Additively Printed through Periodic Layer Rotation Strategies.Image Credit: Zyabich/Shutterstock.com

Nevertheless, anisotropy of the macrostructure happens as a consequence of AM processing parameters such as design processes, melting, fusion, and condensation of the powdered material.

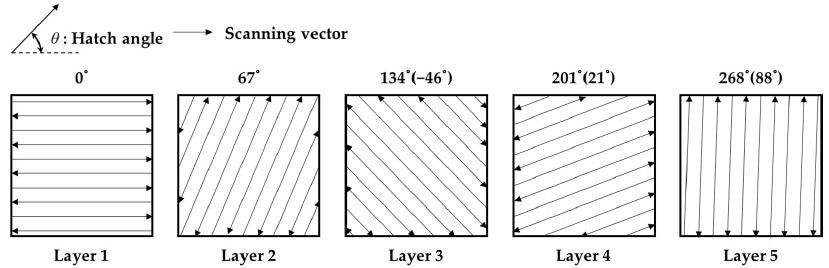

扫描方向决定了宏观结构各向异性,每当将单层堆积在一个路径中时,该方向将作为正交各向异性传达。这里使用古典层压理论简单地叠加个人正骨层。作者使用该策略来确定商品的机械特性是否使用周期性层旋转策略表达同位素。

AM和背后的想法

The basic idea behind additive manufacturing (AM) is to generate the desired shape straightforwardly from 3D digital modeling data. Components are stacked layer-by-layer to develop products, as opposed to traditional machining operations such as casting or cutting.

Because of this fundamental process difference, new procedures (such as configuration for AM) in the additive product development stage can resolve the drawbacks of existing conventional manufacturing techniques and easily control the AM process. As a result, AM is gaining popularity as a desirable fabrication technique for the design and manufacture of high-performance components.

使用栅格扫描策略的图层旋转增量为67°。图片来源:Yang,M。等,材料亚博网站下载

Different Process to Produce Metal AM

Metal AM has a great deal of freedom in molding, including such custom designs; nevertheless, mechanical, and physical properties of the device may suffer due to anisotropy of the configuration depending on the nature of the production process.

The DED method is additively produced by depositing in a local area, whereas the PBF process is a molding technique that involves melting and stacking a flat powder area with the preferential thermal energy of a sensor. The PBF process, in specific, is widely used for the AM process as a typical example of metal AM in manufacturing products.

添加剂制造的限制

该物质在熔化和结晶过程中具有热行为,并且固化的微结构基于热源的运动路径具有方向性。这对合金的机械性能和微观结构有影响。

作为主要情况,残留应力会导致变形,从而导致产物失真或损坏。商品或服务的各向异性属性是微观结构的方向提示。此问题导致良好或服务中的方向性不准确,或影响结构的动态或静态行为,并在设计阶段添加了另一个参数。

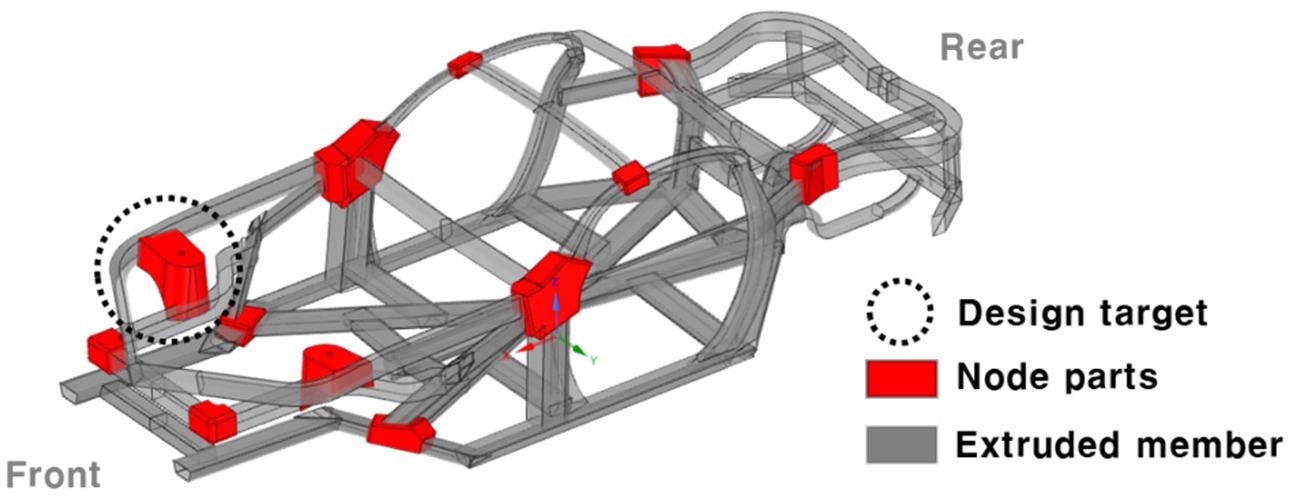

车辆的空间框架和节点部分。图片来源:Yang,M。等,材料亚博网站下载

This behaves as a design restriction and reduces the usefulness of metal AM with high material properties. To address these issues, a periodic layer rotation strategy was used to repress the material's directionality.

偶发旋转层技术的研究过程

研究人员使用偶发旋转层的AM技术来数值评估产品的材料特性。固有应变方法已被广泛用于模拟加性过程。该方法与传统层压理论中用于分类复合作用的方法非常一致。

PBF工艺就像用于制造复合层压板的方法一样,是一种逐层制造技术。完整的系统在两种情况下都分层,并且诱导各向异性。在这种情况下,AM过程的孵化系列具有与复合材料的光纤方向相同的影响。结果,可以使用经典的层压概念来推断产品水平的材料的性能。

The Research Result

AM created a shock absorber handrail for a vehicle to see if the mechanical characteristics can be decently recognized isotropic. The product's compressive strength and vibration tests were compared to the finite element analysis and experimental data. As a result of a comparison, it was stated that the item was macroscopically isotropic because the load-displacement diagram and fracture location, and the resonant frequencies and mode shape, coincided.

Advantage of the Car Printing Using AM Methods

It demonstrates that stress exceeds tensile in the inner zone of the upper and lower flanges. The similar plastic strain findings confirm that the phenomenon was highest in the inner flange area. The experimental data and the FE analysis model had very similar modal forms.

The error in the natural frequency findings was confirmed as the higher-order method ended; nevertheless, it was an essential mistake that showed up because the utterance of components was limited due to FE modeling character traits.

当用较大的零件收集或超过二阶元素雕刻时,可以更好地表达较高订单的固有频率精度。这两个结果都肯定了Fe模型的动态分析的结果,该分析已实施了材料的各向同性特性,并且实验的固有频率和模态形式很好地一致。

References

Yang, M., et al. (2021). A Study on the Mechanical Properties of an Automobile Part Additively Printed through Periodic Layer Rotation Strategies.亚博网站下载材料2022, 15(1), 70; Published: 22 December 2021.https://www.mdpi.com/1996-1944/15/1/70

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of theTerms and conditionsof use of this website.