杂志上发表的新论文Polymershas looked to nature for inspiration on the 3D printing of reinforced shapes that offer good compression strength and energy absorption capabilities.

学习:Mechanical performance of honeycomb sandwich structures built by FDM printing technique.图片来源:matchou/shutterstock.com

As one of the most frequently studied and fabricated bioinspired structures is the honeycomb; these structures are a popular choice for installation in the center of sandwich structures due to their ability to absorb impact.

蜂窝结构的类型是根据其几何形状来表征的。例如,六角形,四面体,金字塔和五角形。

这些结构可在需要保持最佳强度和最小重量的应用中广泛使用。例如,航空航天,汽车,铁路和卫星行业。

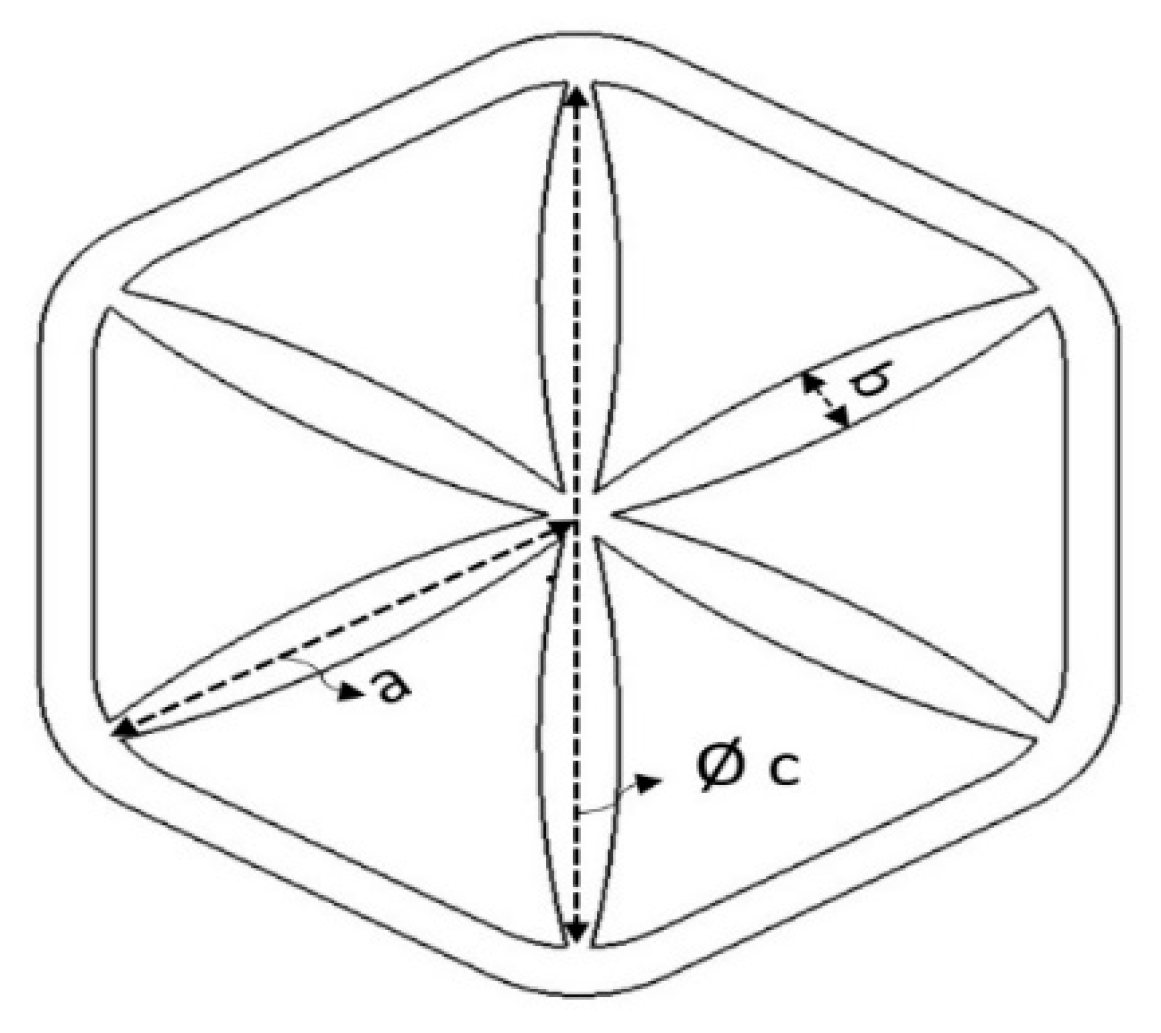

Illustration of honeycomb reinforced starfish structure. Image Credit: Saufi, S., Polymers

Different types of honeycomb structures also exhibit superior energy absorption when evaluated under compression loading; for example, hexagonal honeycombs offer improvements over their rectangular counterparts. The authors cite numerous studies which have compared these differences.

考虑到这一点,作者希望改善常用的蜂窝结构,以改善其能量吸收和对压缩力的抵抗力。

添加剂制造业的进步 - 尤其是3D打印和融合沉积建模(FDM)技术,已经在产品,形状和结构方面开辟了新的复杂程度。

FDM fabricates structures layer by layer, and a wide range of materials are compatible with this process including polymers and composites.

已知细胞尺寸和壁厚是结构承受负载和压力的能力的关键因素。众所周知,在蜂窝中添加二级结构将增加抗压强度和结构吸收能力。

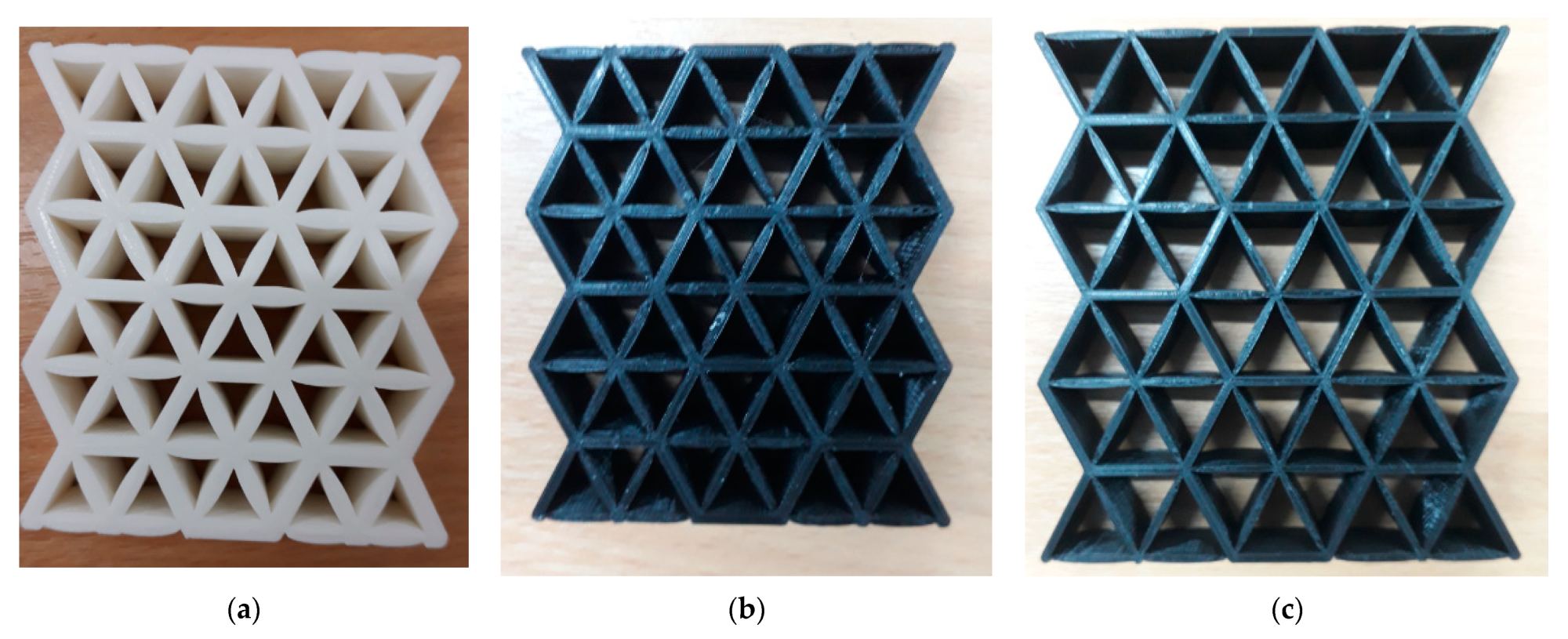

The final 3D printed specimens for (a)细胞尺寸20毫米,厚度为2.5毫米((b) cell size 25 mm, thickness 2 mm and (c)细胞尺寸30毫米,厚度为1.5毫米。图片来源:Saufi,S。,聚合物

由于蜂窝的能量吸收能力与其相对密度密切相关,因此作者认为,用海星形状增强六角形蜂窝结构可能会产生比单独使用的六角形蜂窝更强大,更耐压的结构。

他们使用3D打印技术来生成一系列带有海星形钢筋的六角形蜂窝结构,并使用一系列的细胞壁厚度和细胞尺寸打印它们。

结构是由聚乳酸(PLA)制成的,并使用实体设计®software prior to conversion to standard tessellation language (STL) format for 3D printing.

除了研究海星形增强剂的特定特性外,该研究还旨在研究生物启发结构的更一般的能量吸收能力,并使用多种工具来评估其能量吸收,特定的能量吸收,压缩力效率,损坏力效率,粉碎力效率,细胞大小和细胞壁厚对这些指标的影响。

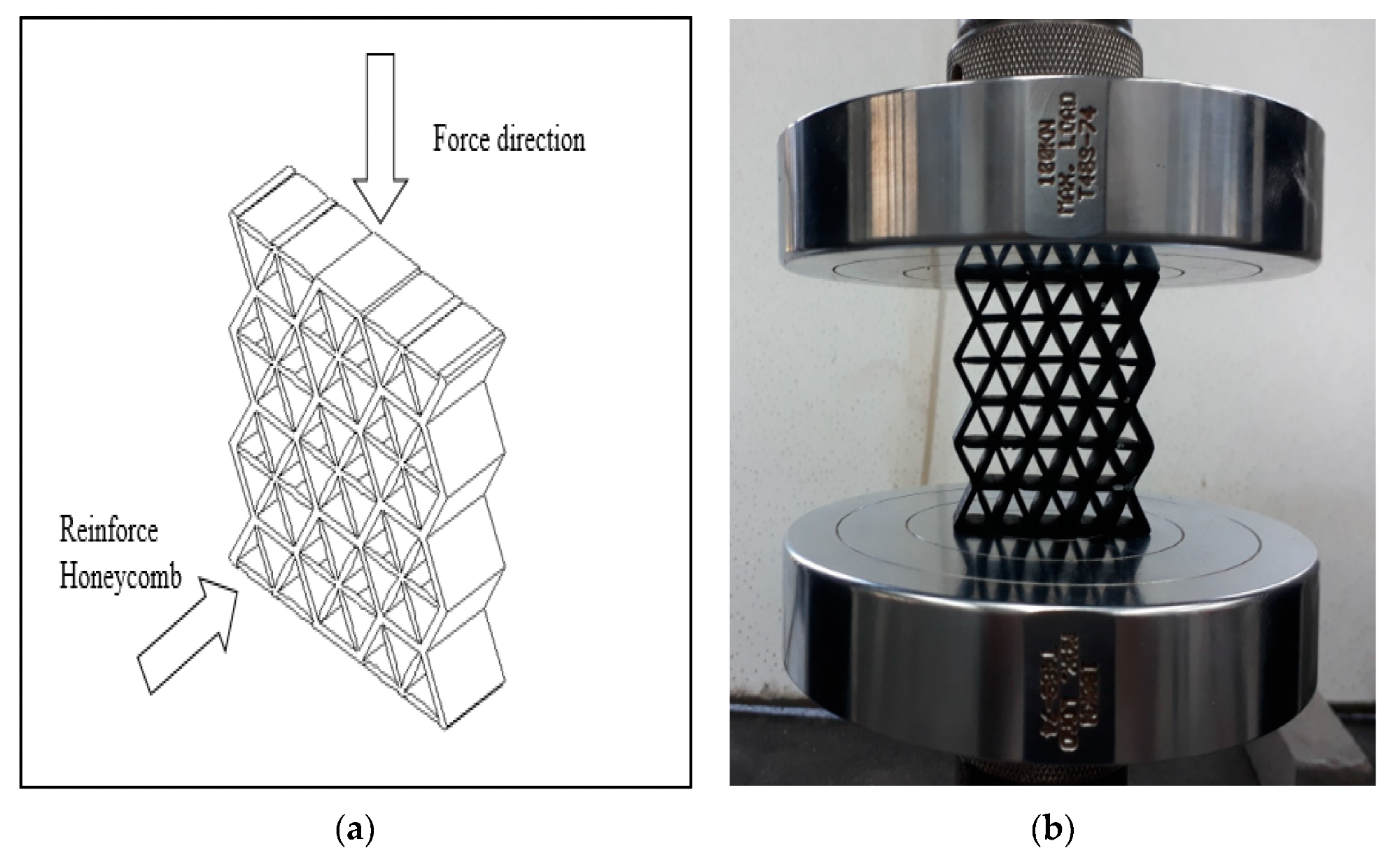

In order to calculate the structures’ capacity for energy absorption, results from compression tests were plotted in a load-displacement curve to determine a maximum peak value – essentially, the maximum load the structure can resist. The energy absorption value was calculated based on the area under the load-displacement curve.

该研究表明,由于细胞尺寸和细胞壁的厚度,结构表现出较高的峰值负荷能力。最值得注意的是,壁厚之间的比较显示出均匀的模式 - 壁厚的增加增加导致峰值负载增加,而与核心大小无关。还发现随着细胞尺寸的增加,峰负荷也会减小。

有趣的是,就压缩行为而言,最小的壁厚比较大的壁厚表现出改善的性能。实际上注意到,随着壁厚的提高,无论细胞大小如何,效率都会降低。

(a) Schematic of sample orientation during test. (b)测试期间样品取向。图片来源:Saufi,S。,聚合物

It was also determined that a higher crushing force efficiency value was generated from a smaller energy absorption value - as wall thickness increases, crushing force efficiency decreases, but energy absorption increases.

作者提出,可以进一步探索这些发现,并通过研究改善结构关节或节点性能的手段进一步优化结构。还强调说,在动态装载条件下结构的能力可能被证明是进一步的调查途径。

The development of these more robust reinforced honeycomb structures could be key to improving safety and crash resistance in a range of transport and other applications.

参考

Gohar,S.,Hussain,G.,Ali,A。,&Ahmad,H.2021。由FDM打印技术构建的蜂窝状三明治结构的机械性能。热塑性复合材料杂志。亚博网站下载https://journals.sagepub.com/doi/10.1177/0892705721997892

Saufi, S. A.S.A., M. Y.M. Zuhri, M. L. Dezaki, S. M. Sapuan, R. A. Ilyas, A. As’arry, M. K.A. Ariffin, and M. Bodaghi 2021. "Compression Behaviour of Bio-Inspired Honeycomb Reinforced Starfish Shape Structures Using 3D Printing Technology"Polymers13, no. 24: 4388.https://www.mdpi.com/2073-4360/13/24/4388

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of theTerms and conditionsof use of this website.