在2021年Utech Europe,Lanxess将展示其在聚氨酯行业中最全面的产品组合。贸易展览会将于11月16日至18日在荷兰的马斯特里赫特举行。该公司还将推出其聚合物添加剂范围,这是自收购Emerald Kalama Chemical以来其投资组合的最新成员。

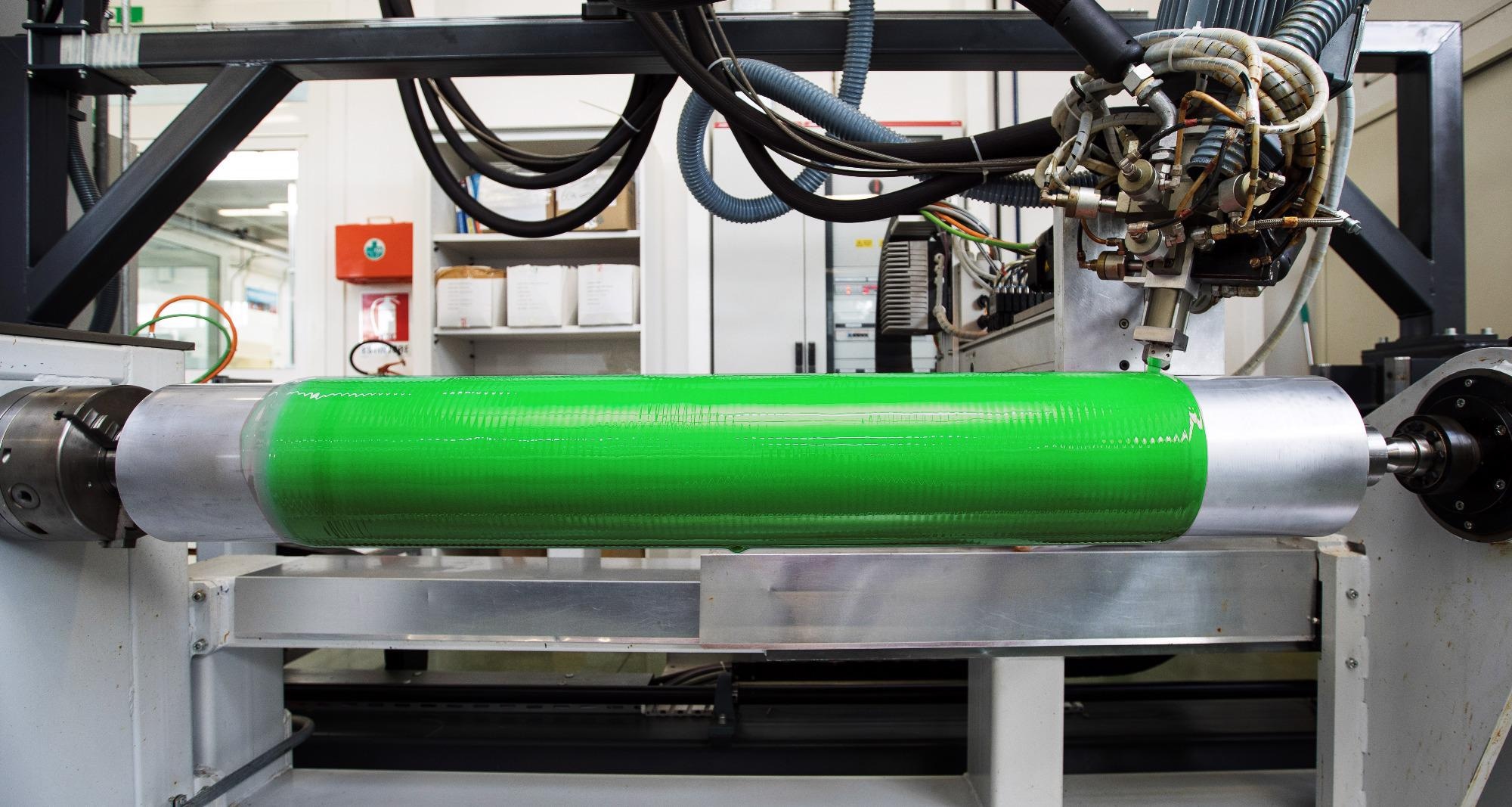

Lanxess开发了一系列包含可再生原材料的MDI聚醚前聚合物。亚博网站下载这些产品以品牌名称脂肪绿色销售,适合替代现有的基于化石的聚醚前聚合物,并允许PU处理器生产使用降低的CO的组件2footprint. Image Credit: LANXESS AG

Lanxess开发了一系列包含可再生原材料的MDI聚醚前聚合物。亚博网站下载这些产品以品牌名称脂肪绿色销售,适合替代现有的基于化石的聚醚前聚合物,并允许PU处理器生产使用降低的CO的组件2footprint. Image Credit: LANXESS AG

专业化学品公司提供的广泛投资组合不仅包括添加剂,包括阻燃剂,增塑剂,交联,催化剂和水解稳定剂,还包括用于刚性和柔性泡沫,涂料,弹性,弹性剂,密封剂,密封剂和粘合剂的预聚合物。LANXESS投资组合的最新添加包括一系列以品牌模量销售的修饰符,并专门用于反应性聚氨酯系统。

PURe Sustainability

At a conference scheduled to be held on November 16 in parallel with the trade fair, employees of the Urethane Systems (URE) business unit will be giving four presentations focusing on sustainable and ecofriendly solutions. The presentations cover the following topics:

- 一种用于PU的新型热铸 /冷验系统,可节省能量和削减CO2排放

- 脂肪绿色 - 一种新的基于生物的PU弹性体解决方案

- Pellart – Water-based adhesive agent systems for surface-treated polyolefins

- Low free urethane prepolymers as the building blocks for high-performance protective coatings

These presentations reflect LANXESS’s understanding of sustainability requirements in the PU industry and concentrate on the use of low free technology, the shift from solvent- to water-based systems, the rising demand for renewable, bio-based raw materials and opportunities for customers to reduce their carbon footprint during the processing stage.

“Adiprene low free technology helps to reduce the level of VOC components in the final prepolymer products. In particular, the content of free diisocyanates is reduced,URE营销与开发负责人迈克尔·蒂姆(Michael Timm)说。剩余的单体含量小于0.1%。

PU的热铸 /冷验系统可节省能源

With Adiprene Green, LANXESS has developed a range of bio-based prepolymers that benefit from the replacement of fossil polyols with commercially available, bio-based polyols. “我们的基于聚醚的MDI系统范围使用淀粉的聚醚多元醇。这些系统是现有的,基于化石的聚醚前聚合物和用于产生高度抗性聚氨酯弹性体的系统的理想掉落,”says Gerald King, Head of Application Technology EMEA at URE. Depending on the system, the carbon footprint can be anywhere between 20% and 30% lower than that of fossil-based prepolymer systems.

水性粘合剂系统用于表面处理的聚芬蛋白

With Pellart PR 28 and Pellart PR 29, LANXESS Urethane Systems has developed a range of new adhesive agents for polyolefin-based materials in order to drive the transition toward water-based solutions. These primers act as an adhesive bridge between the substrate and adhesive/coating to ensure a highly durable bond.

结合诸如Trixene Aqua Bi 201(阻塞)和Pellart XL 210之类的交联链,这些粘合剂具有出色的物理和化学特性,例如在预处理的聚烯烃表面和粘合剂上具有出色的粘附性。它们的特征是它们的高热量和耐水性和高初始强度。

在建筑应用中智能且可持续的泡沫阻燃剂

The increasing global awareness of climate change and energy consumption is expected to lead to heightened interest in rigid polyurethane foam as an insulating material, a development that would also increase the importance of fire safety in these construction applications. A range of different flame retardants is used in rigid polyurethane foams to fulfill these requirements, with one of the most common and effective groups of flame retardants being phosphorus-based – including chlorinated phosphate esters and halogen-free compounds. At UTECH Europe 2021, Dr. Heiko Tebbe, Head of Application Technology EMEA in the LANXESS business unit Polymer Additives (PLA), will be holding a presentation entitled“用于刚性聚氨酯泡沫的新型基于磷的阻燃剂。”

在原定于2021年11月17日举行的演讲中,他将谈论Levagard 2000和Levagard 2100,这是两个新的,由lanxess开发的新的,基于磷的火焰阻燃剂。这些产品在刚性聚氨酯泡沫制剂中的性能与其他常见的阻燃剂进行了比较。Tebbe还将强调新火焰阻燃剂在易燃性测试中的有效性,并解释这些产品对加工,稳定性和泡沫性能的影响。结果表明,新的阻燃剂可以在满足刚性聚氨酯泡沫的要求中发挥至关重要的作用。

Lanxess为工业领域提供广泛的阻燃剂,包括基于磷的Levagard和Disflamoll以及含溴的反应性,具有溴的产品PHT4-二醇。尤其是在建筑行业中,这些化合物是可持续火焰溶液的重要组成部分。尤其是聚合物和反应性的阻燃添加剂符合当前环境保护和健康的要求,而没有导致防火特征的妥协。

绩效改进作为对递送瓶颈的回应

原材料供亚博网站下载应不足,而与大流行有关的交货瓶颈影响了整个行业的供应链。但是,由于模量修饰符,在TPU和案例应用中,可以减少配方中多元醇和异氰酸酯的使用,同时可以改善物理性能。

Modulast PUR是一种最高纯度和最低羟基含量的二苯甲酸酯。修饰符确保成品中的特殊颜色是低模型,并提供了改善的持久性。在某种程度上,模量PUR也可以用作配方中更昂贵的多元醇的替代品。

高性能修饰剂模量ACE的特征是其始终如一的低羟基含量。对于需要低气味,极低的渗出以及良好的反弹和压缩组的高性能应用程序的绝佳选择。

来源:https://lanxess.com/