Boosting efficiency through digitalization - almost no branch of industry can evade it. Also operators of press shops are increasingly networking their production. But - regardless of whether it's a single press or press lines - it's not always necessary to replace the entire plant in order to stay up to date Retrofitting existing lines, true to the principle of "sensible evolution instead of cost-intensive revolution", is often the order of the day.

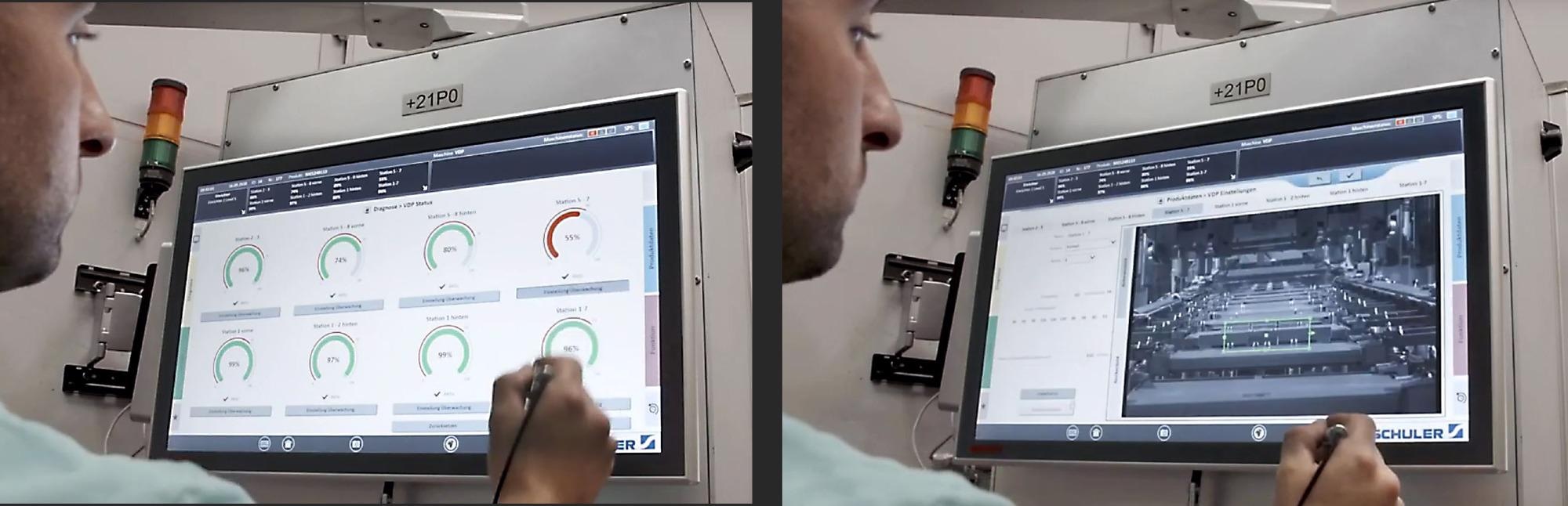

Digitization in the press shop. Image Credit: IDS Imaging Development Systems GmbH

借助视觉模具保护,Göppingen的Schuler Pressen GmbH提供了一种解决方案,可避免昂贵的模具损坏及其在冲压和形成技术中的相应成本 - 可用于现有线路。配备了来自IDS成像开发系统GmbH和智能软件的工业摄像头,可以根据需要监视生产过程。

Application

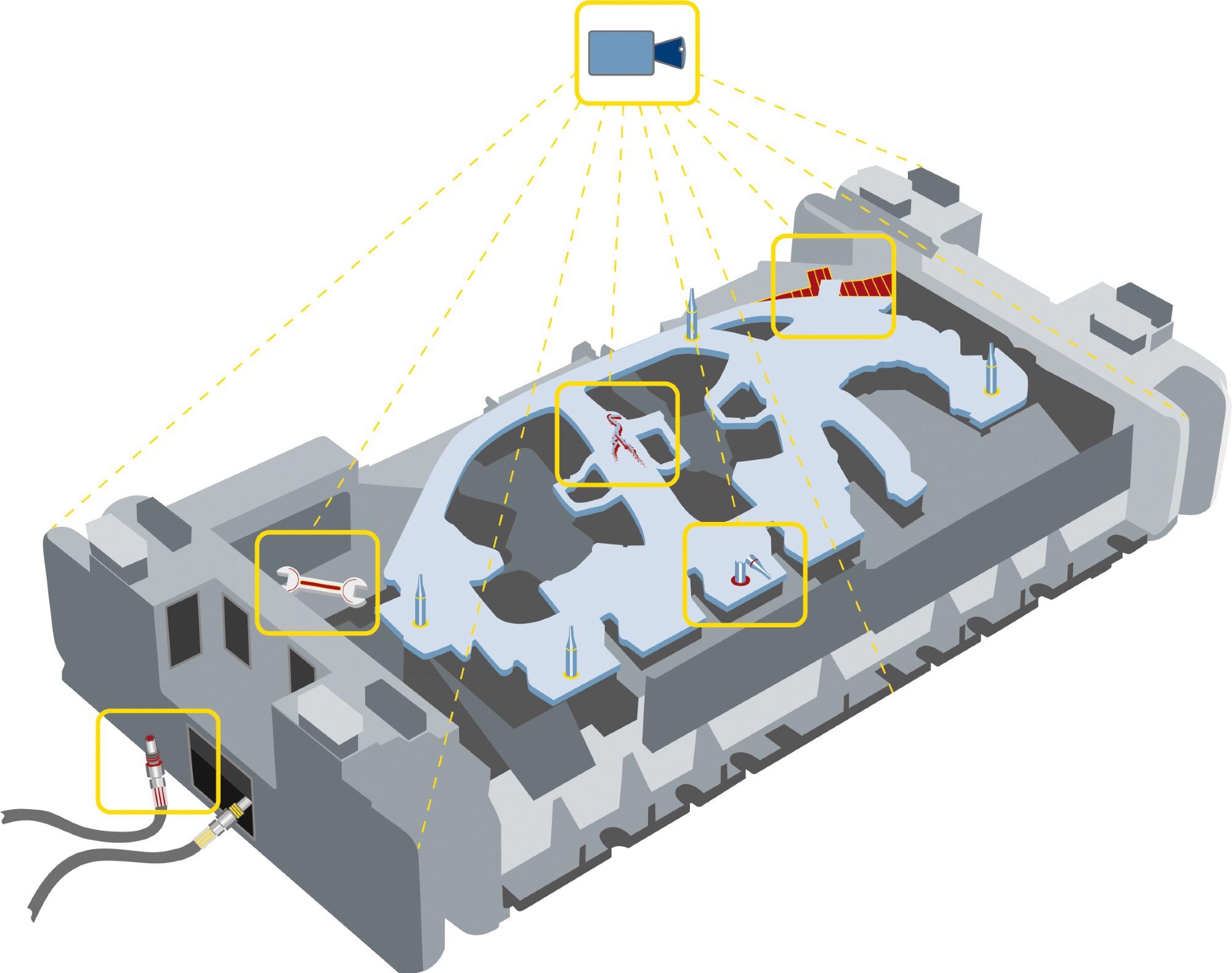

The principle of the system is simple: Visual Die Protection (VDP) detects possible causes of die damage in the press shop at an early stage and stops the line in fractions of a second before damage and downtime occur. Different monitoring functions can be set up for the various areas in the press installation space. This way, a wide range of error sources can be covered to prevent unforeseen incidents. The probability of failure is reduced and the safe operation of the systems is ensured.

控制功能从检查组件位置到异物检测和过程中的检查,再到对单个工具功能的目标监视。例如,如果在模具中检测到一个异物(例如上一个新闻通行证中的一块金属碎片),则新闻界会自动停止,以便外国物体无法将其推入模具表面或造成损坏。

The system detects unexpected causes of faults and stops the press. Image Credit: IDS Imaging Development Systems GmbH

The system can be used for a wide range of monitoring tasks, even outside the actual pressing plant. Thanks to the easy retrofitting of existing systems and the wide range of applications, the monitoring functions can be set up in just a few minutes. Accordingly, customers benefit immediately from camerabased tool protection. That also applies to non-Schuler systems. With the help of product data handling, even monitoring of already set-up tools can be loaded and monitored from the first press stroke Camera

Camera

Schuler系统所基于的图像数据由IDS的UEYE CP工业摄像机提供。CP代表“紧凑型功率”,象征着各种工业应用的紧凑,视觉电源包。它们具有广泛的像素预处理提供最大功能,并且非常适合多摄像机系统,这要归功于内部120 MB图像存储器用于缓冲图像序列。

大小仅为29 x 29 x 29毫米的GIGE摄像机在光灵敏度,动态范围和颜色再现方面得分特别好。这使得它们是针对即使在质量保证或自动化等弱光条件下也需要提供完美结果的应用程序的预定。

图像数据的质量使我们说服了我们。即使在新闻店中相当不利的照明条件下,相机也为我们的检查系统提供了理想的原始材料。

Christoph Pölzl , Project Manager in the Digital Solutions division, Schuler Pressen GmbH

为了集成,该公司使用了IDS摄像机管理器,这是一种中心方便的工具,用于管理所有UEYE工业摄像机。

一个或多个IDS工业相机监视工具室。图片来源:IDS成像开发系统GmbH

Outlook

自2019年以来,Visual Die Protection一直在市场上投放市场,此后一直确立自己的冲压和形成技术作为可靠的视觉保护工具。借助人工智能和工业摄像机,它在新闻店提供了清晰的视野。

For the future, we expect a continuously growing market.

Schuler Pressen GmbH的数字解决方案部项目经理ChristophPölzl。

In addition to process and tool monitoring, further applications in the area of in-process quality monitoring are added. The diagnostic tools for linking image and process data are also constantly being expanded. So the evolution continues and perhaps in the end it will lead to a small revolution?

关于相机家庭https://en.ids-imaging.com/ueye-instulial-cameras.html#ueye-cp