Aug 30 2019

EV Group (EVG), a leading supplier of wafer bonding and lithography equipment for the MEMS, nanotechnology and semiconductor markets, today announced that it has teamed up with SCHOTT, one of the world's leading technology groups in the areas of specialty glass and glass ceramics, to demonstrate the readiness of 300-mm (12 inch) nanoimprint lithography (NIL) for high-volume patterning of high-refractive index (HRI) glass wafers used in the manufacture of waveguides/light guides for next-generation augmented/mixed reality (AR/MR) headsets.

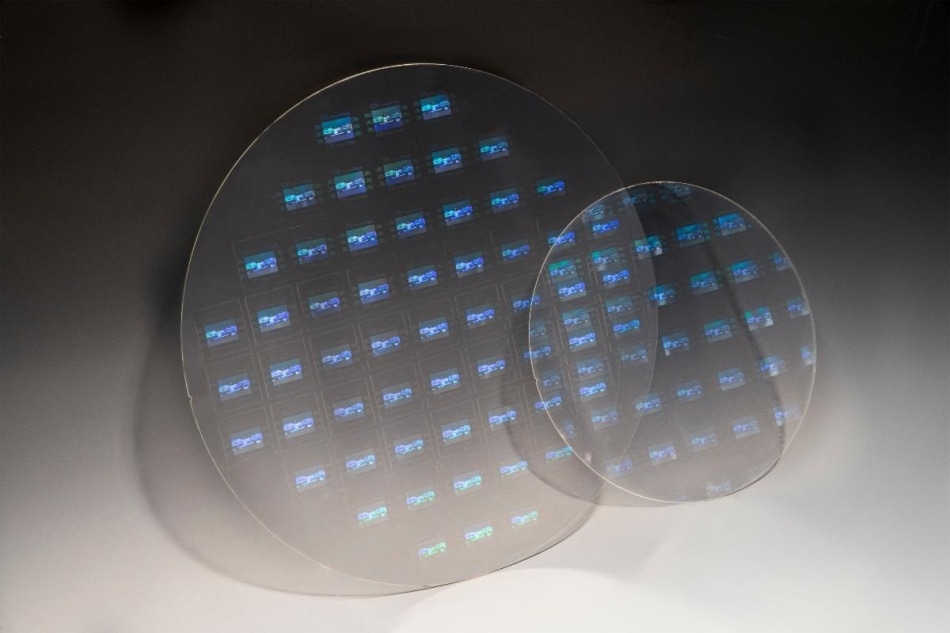

300毫米和200毫米Schott Realview™玻璃基材印在Evg®Hercules®NIL系统中,利用Smartnil®UV-NIL技术。

300毫米和200毫米Schott Realview™玻璃基材印在Evg®Hercules®NIL系统中,利用Smartnil®UV-NIL技术。

The partnership involves EVG's proprietary SmartNIL®process and SCHOTT RealView™ high-refractive index glass wafers, and will be carried out within EVG's NILPhotonics®Competence Center at the company's headquarters in Austria. SCHOTT will showcase a 300-mm SCHOTT RealView™ glass wafer patterned with EVG's SmartNIL technology at the China International Optoelectronic Expo (CIOE), to be held September 4-7 at the Shenzhen Convention Center.

"Scaling up to 300-mm manufacturing of high-refractive index glass wafers is critical to achieving the production volumes at the economies of scale that our customers need to meet growing market demand for today's and tomorrow's leading AR/MR devices,"stated Dr. Ruediger Sprengard, Head of Augmented Reality at SCHOTT.“通过这项联合努力,EVG和Schott正在展示今天300毫米HRI玻璃制造的设备和供应链准备。”app亚博体育

Until now, the use of NIL to pattern glass substrates with structures for photonics applications has been limited to 200-mm substrates. The migration to 300-mm wafer processing is an important step forward in bringing AR/MR headsets into the mass consumer and industrial markets. However, maintaining high substrate quality and process uniformity on these larger substrates is difficult to control, and requires advanced automation and process control capabilities. EVG's SmartNIL technology is the result of years of research, development and field experience to address the needs of nanopatterning, and has been field proven to be easily scalable from die-level sample sizes all the way up to large-area substrates. This past June, EVG introduced the HERCULES®NIL 300毫米,将Smartnil带入300毫米制造业,以支持各种设备和应用的生产需求,包括AR,MR和虚拟现实(VR)耳机的光学设备,以及3D传感器,生物密码设备,纳米光子学和血浆。

"Established in 2014, EVG's NILPhotonics Competence Center provides an open access innovation incubator for a diverse set of partners and companies across the NIL supply chain to collaborate with EVG to shorten development cycles and time to market for innovative photonic devices and applications,"EV Group公司技术发展和IP总监Markus Wimplinger表示。“我们很高兴与Schott这样的公司合作,以展示EVG的零解决方案的价值,不仅可以实现新技术和流程的开发,而且还加速了他们对大众市场的介绍。我们与Schott所做的这项目前的工作证明了成熟度NIL设备和流app亚博体育程,并为300毫米制造业奠定了基础,用于各种令人兴奋的新光子产品和应用。”

SCHOTT RealView™ high-refractive index glass wafers are a key component in leading AR/MR devices and available in mass production. The product portfolio offers refractive indices up to 1.9, enabling deeply immersive AR/MR applications with a wider field of view of up to 65 degrees. SCHOTT unveiled the first generation of SCHOTT RealView™ in 2018 after years of research and development in cooperation with AR hardware makers. Just one year after its market launch, the high-end product won the prestigious SID Display Industry Award 2019.

一份白皮书,详细介绍了EVG对HRI眼镜的Smartnil技术的好处,可以从EVG的网站下载:https://www.evgroup.com/fileadmin/media/products/NIL/SmartNIL_with_High_Refractive_Index_White_Paper.pdf

Source:http://www.evgroup.com/en/