Rigaku Corporation发表了一份申请报告,展示了Rigaku Hypix-3000混合像素阵列多维检测器的性能,以2D X射线衍射图像的快门测量。

为了捕获材料在熔化,固化或晶体相变的时刻,通过原位X射亚博网站下载线衍射测量,需要尽可能短在每个温度下的X射线衍射图像的采集时间。0D和1D检测器需要时间来扫描检测器并准备操作,而常规2D检测器则需要在计数和读取数据之间打开并关闭X射线快门。

在2D模式下的Hypix-3000检测器可以在不扫描检测器的情况下获取X射线衍射图像。Hypix-3000检测器内部有两个计数器。它们之间的切换允许无休止的时间进行测量,并可以对2D X射线衍射图像进行无快速测量,这使观察结晶状态的快速变化成为可能。

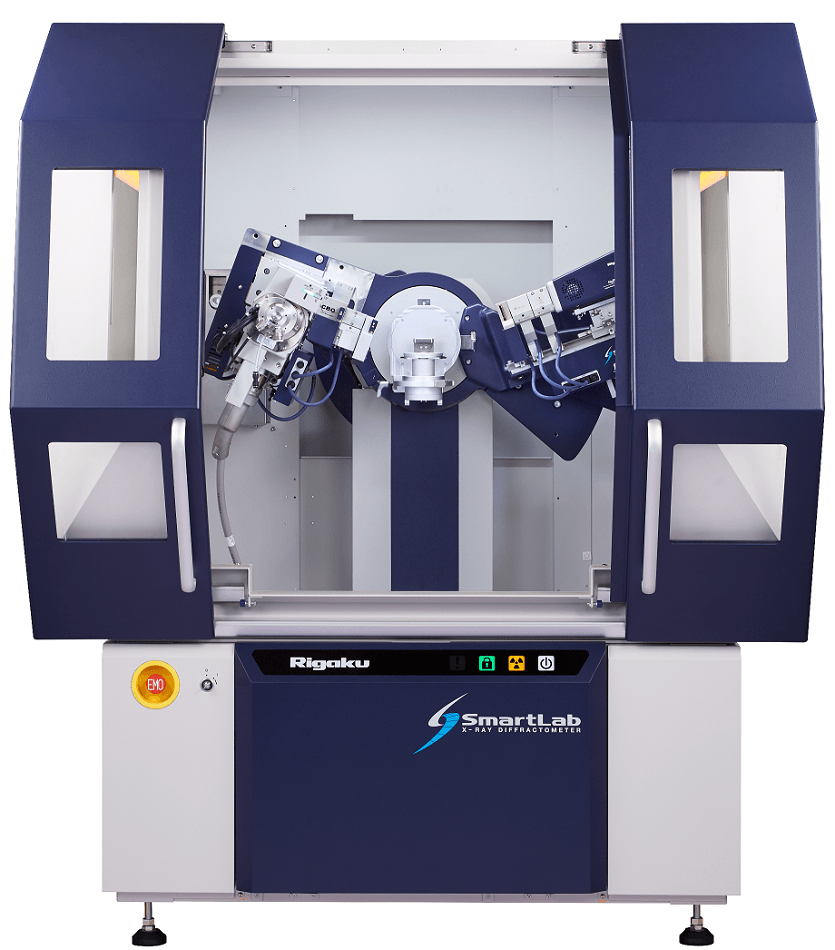

Hypix-3000混合像素阵列检测器可在新的Rigaku SmartLab智能多功能X射线衍射仪,并与新的PhotonMax High-Flux 9 kW旋转阳极X射线源相结合,允许使用单个检测器处理所有应用程序,从而消除了为不同应用程序准备和切换单个检测器的需求。

Rigaku Application Note B-XRD 1105 - “High-speed in-situ measurement of Al metal melting process” – details the recording of 2D X-ray diffraction images of an aluminum plate sample. Images were recorded every 0.5 seconds while rapidly increasing the temperature at 300˚C/min.

Continuous Debye rings - concentric diffraction rings obtained from polycrystalline thin films - from the aluminum plate were observed at room temperature, revealing that the aluminum crystal had fine grains before heating. During the increase in temperature, the Debye rings became dotted, indicating that grain growth occurred due to heating. When the temperature was increased even further, the Debye rings eventually disappeared due to the melting of the aluminum. It was confirmed that there was a temperature range where the continuity of the Debye rings increased just before melting. This was the moment when the grain boundaries of the aluminum melted and the liquid phase and minute crystal grains coexisted.

有关Rigaku的X射线衍射(XRD)仪器的更多信息,请访问https://www.rigaku.com/en/products/xrd