Apr 18 2018

每年,腐蚀材料的影响使全球经济损失超过1万亿美元。亚博网站下载一些合金暴露于极端的温度和压力,导致氧化膜的形成,从而加速了合金的分解。

The exact reasons that make these high-stress and high-temperature conditions so favorable for corrosion are unclear, particularly in microelectromechanical devices. Chinese researchers have begun to work toward understanding the causes for corrosion of materials under mechanical stress. They have reported their study in theJournal of Applied Physics, fromAIP出版。

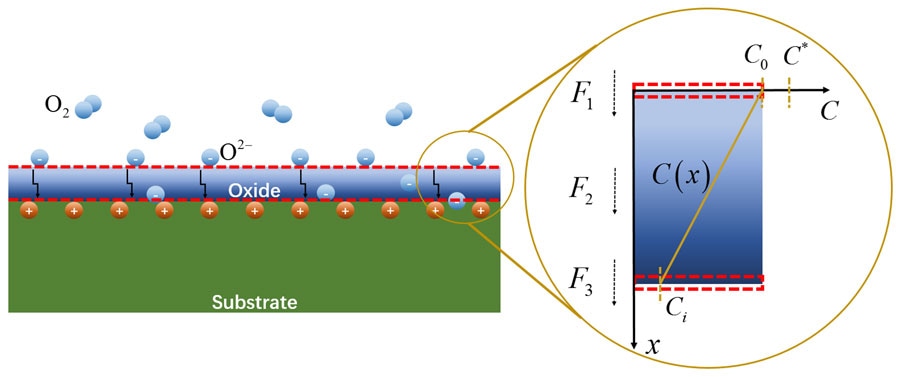

氧化物膜/底物系统和氧化过程的示意图。在第一阶段,通量会影响氧气从气体到气体/氧化物界面的扩散和吸附。(信用:Mengkun Yue)

氧化物膜/底物系统和氧化过程的示意图。在第一阶段,通量会影响氧气从气体到气体/氧化物界面的扩散和吸附。(信用:Mengkun Yue)

Tsinghua大学Xue Feng教授领导的研究小组解释了机械应力对氧化过程的影响。他们的模型利用氧化动力学来描述应力如何改变界面处的化学反应并引起氧化,以及应力如何影响整个氧化物层扩散的氧化物种。

“Our work is in the direction of fundamental research, but it is indeed based on engineering problems,”冯指出。“We expect that it provides guidelines for more accurate predictions in engineering applications, including better designs to compensate for material and system failure by taking into account the oxidation process.”

几年来,氧化和物理压力的化学力学偶联研究的重点是将应力与合金腐蚀的两个不同属性之一相关联。尤其是,应力有助于加速在设备和周围空气中存在的氧气和氧气之间材料表面上进行的氧化。此外,应力改变了氧化化合物通过材料的纳米结构扩散的方式。

团队的研究将氧化过程和压力结合在一起。首先,通常是腐蚀合金的底物通过吸收氧气形成金属氧化物层。该层允许更多的氧通过它扩散,这可以与氧化界面后面的随后合金层反应。

“我们在这里的工作主要处理第二阶段和第三阶段,其中,由于氧化物形成本身而引起的外部施加机械载荷或本质上产生的应力,可能会影响扩散和化学反应过程”该论文的另一位作者Tsinghua University的Mengkun Yue补充说。

The model presented by the group predicted that, on compression, materials under heavy loads absorb less oxygen. Likewise, the stresses pulling the material apart create additional space for oxygen to permeate the alloy.

研究人员对SIO样品进行了测试2借助于多层干涉测量法生长在SI基板上。该方法以前是由其他研究人员证明的,理论预测与数据一致。

Xufei Fang, an author on the paper at Max Planck Institute for Iron Research, expects that the verification of a unified model for stress-oxidation coupling can facilitate enhancements of microelectromechanical devices. Under stress or at elevated temperatures, it is possible for these devices to go through significantly more oxidation owing to their large surface-area-to-volume ratio.

“We expect a more general application of our model and we will develop our model further, in the next steps, to apply them to microscale systems,”方补充说。