2015年12月26日

A team led by researchers from the UCLA Henry Samueli School of Engineering and Applied Science has created a super-strong yet light structural metal with extremely high specific strength and modulus, or stiffness-to-weight ratio. The new metal is composed of magnesium infused with a dense and even dispersal of ceramic silicon carbide nanoparticles. It could be used to make lighter airplanes, spacecraft, and cars, helping to improve fuel efficiency, as well as in mobile electronics and biomedical devices.

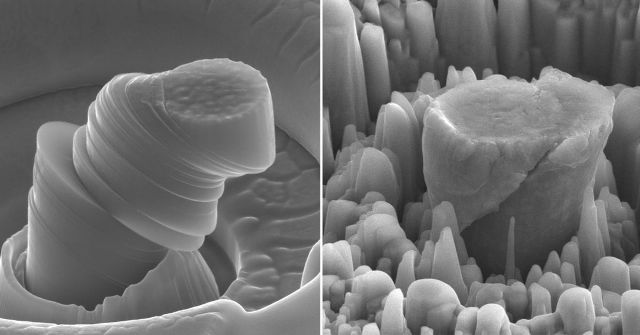

在左侧,纯金属的变形样品;在右边,由镁制成的强大新金属用碳化硅纳米颗粒制成。yabo214每个中央微柱约为4微米。学分:加州大学洛杉矶分校的舒适性实验室

在左侧,纯金属的变形样品;在右边,由镁制成的强大新金属用碳化硅纳米颗粒制成。yabo214每个中央微柱约为4微米。学分:加州大学洛杉矶分校的舒适性实验室

为了创建超强但轻巧的金属,该团队找到了一种新的方法来分散和稳定熔融金属中的纳米颗粒。yabo214他们还开发了一种可扩展的制造方法,该方法可以为更高性能的轻质金属铺平道路。该研究今天在自然界发表。

“It’s been proposed that nanoparticles could really enhance the strength of metals without damaging their plasticity, especially light metals like magnesium, but no groups have been able to disperse ceramic nanoparticles in molten metals until now,” said Xiaochun Li, the principal investigator on the research and Raytheon Chair in Manufacturing Engineering at UCLA. “With an infusion of physics and materials processing, our method paves a new way to enhance the performance of many different kinds of metals by evenly infusing dense nanoparticles to enhance the performance of metals to meet energy and sustainability challenges in today’s society.”

Structural metals are load-bearing metals; they are used in buildings and vehicles. Magnesium, at just two-thirds the density of aluminum, is the lightest structural metal. Silicon carbide is an ultra-hard ceramic commonly used in industrial cutting blades. The researchers’ technique of infusing a large number of silicon carbide particles smaller than 100 nanometers into magnesium added significant strength, stiffness, plasticity and durability under high temperatures.

研究人员的新型碳化硅注入的镁表明了特定强度的创纪录水平 - 材料在破裂前可以承受多少重量以及特定的模量 - 材料的刚度与重量比。它在高温下还显示出卓越的稳定性。

Ceramic particles have long been considered as a potential way to make metals stronger. However, with microscale ceramic particles, the infusion process results in a loss of plasticity.

Nanoscale particles, by contrast, can enhance strength while maintaining or even improving metals’ plasticity. But nanoscale ceramic particles tend to clump together rather than dispersing evenly, due to the tendency of small particles to attract one other.

To counteract this issue, researchers dispersed the particles into a molten magnesium zinc alloy. The newly discovered nanoparticle dispersion relies on the kinetic energy in the particles’ movement. This stabilizes the particles’ dispersion and prevents clumping.

To further enhance the new metal’s strength, the researchers used a technique called high-pressure torsion to compress it.

李说:“到目前为止,我们获得的结果只是刮擦了具有革命性和功能的新金属的隐藏宝藏的表面。”

The new metal (more accurately called a metal nanocomposite) is about 14 percent silicon carbide nanoparticles and 86 percent magnesium. The researchers noted that magnesium is an abundant resource and that scaling up its use would not cause environmental damage.

该论文的首席作者是Lian-Yi Chen,他在UCLA的Li Scivicciant Laboratory中作为博士后学者进行了研究。Chen现在是密苏里科学技术大学机械和航空工程助理教授。亚博老虎机网登录

加州大学洛杉矶分校(UCLA)的其他作者包括材料科学与工程研究生Jia-Quan Xu;亚博网站下载亚博老虎机网登录助理开发工程师Marta Pozuelo;以及材料科学与工程学教授Jenn-Ming Yang。亚博网站下载亚博老虎机网登录

The other authors on the paper are Hongseok Choi, of Clemson University; Xiaolong Ma, of North Carolina State University; Sanjit Bhowmick of Hysitron, Inc. of Minneapolis; and Suveen Mathaudhu of UC Riverside.

该研究部分由美国国家标准技术研究所资助。

Source:http://www.ucla.edu/