Saint-Gobain Seals’ OmniSeal® spring-energized anti-blowout seal has been qualified as a static seal in rocket engine check valves for the aerospace industry.

Check valves are flow control devices that allow the flow of pressurized fluid (liquid or gas) in one direction only. In normal operations, check valves are in shut-off position where sealing is secured by static seals that are designed to withstand any blowout. Once the fluid pressure reaches or exceeds the rated threshold pressure, the valve opens and allows the fluid to transfer from a high pressure to low pressure side. Decrease in pressure to a level below the threshold pressure causes the valve to go back to its shut-off position. Check valves are also common in the oil and gas industry as well as in applications for pumps, chemical processing and fluid transfer.

In most cases, design engineers integrate check valves into their rocket engine designs. The role of seals in these vales is thus very critical in overall launch missions. Anti-blowout seals are used in check valves to retain pressurized fluid on the high pressure side while preventing blowout of the seal from the housing. Under high pressure as well as rapid change of pressure across the seal surface, retaining the seal in its housing is very challenging. Once the dynamic sealing surface of the hardware disengages from the sealing lip, there is a tendency of the seal to be blown away from the housing due to residual pressure around the seal. Normally seat seals, simple blocks of PTFE, are used in check valves but these seals’ performance are not consistent and over time, the seat seals experience permanent deformation resulting in leakage.

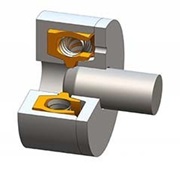

Saint-Gobain Seals的防吹封密封,源自其Omniseal®103A配置,由带有弹簧耐加工的聚合物夹克组成。夹克由专有的Fluoroloy®材料制成,而弹簧可以用不锈钢和Elgiloy®在内的材料制成。亚博网站下载弹簧可以根据止回阀的工作条件进行特殊过程进行热处理和清洁。An example of a general Saint-Gobain Seals’ anti-blowout seal in a rod sealing application is shown in the illustration at left (note: this illustration is different than the seal used in the actual check valve application, which is custom-designed). The seals in the check valve application operate from cryogenic temperature up to 575°F (302°C) and can withstand pressure up to 6,000 psi (414 bar).

火箭发动机止回阀中使用的Omniseal®反吹封密封的目的是密封加压气体和液化气体,从低于-300°F(-184°C)以下的温度下达122°F(50°C)。该密封件的压力接近3,000 psi(207 bar)。Fluoroloy®夹克材料具有出色的耐磨性,抗变形性,低摩擦系数和非常冷的温度功能。Omniseal®反吹牛密封件旨在用于数百个周期的操作,而不会泄漏。

The OmniSeal® product line is available in multiple designs such as 103A, APS, Spring Ring II, 400A, RP II and RACO™ 1100A and are also offered in various custom designs. These designs include seal jackets in various Fluoroloy® materials and springs in various configurations. Saint-Gobain Seals’ sealing solutions have been used in launch vehicles such as the Atlas V rocket engine (which launched the Mars Rover Curiosity into space), Delta IV Heavy rocket and Falcon 9 rocket. Their solutions have also been used in other industries (oil and gas, automotive, life sciences, electronics and industrial) and in applications such as environmentally-friendly industrial dyeing process equipment, chemical injection pumps, the world’s first subsea gas compression station and chemical analyzers.

请拜访www.seals.saint-gobain.comfor more information on spring-energized seals.