Biovinyl是由Teknor Apex开发的,是由DOW真生生物塑料制成的一种新系列的柔性乙烯基化合物。

生物丝烯基柔性乙烯基化合物

生物丝烯基柔性乙烯基化合物

The compounds have been fabricated for manufacturers, who look for minimizing the carbon footprint of their products.

Biovinyl化合物使用DOW电气和电信(DOW E&T)生产的基于生物的增塑剂,Dow Chemical的一个划分。Teknor Apex的生物燃料化合物的全球变暖潜力低于聚烯树脂和PLA生物塑料的全球变暖潜力。由于道琼斯陶当的振动剂来自天然可用的蔬菜物质,因此在其他生物衍生的塑料原料(如玉米淀粉)中通常不会发生供需力的影响。此外,陶氏振兴比常见的邻苯二甲酸盐具有更高的增塑效率。

Recently, Teknor Apex and Dow has entered into a joint collaboration agreement, under which Teknor Apex has received the exclusive right to sell the flexible vinyl compounds made from DOW ECOLIBRIUM plasticizers in the North American market. Life cycle analysis tests that have been performed by Dow and verified by a third party reveal that each ton of bio-based vinyl compound helps the industry to decrease carbon dioxide emissions by 41% or 0.7 ton.

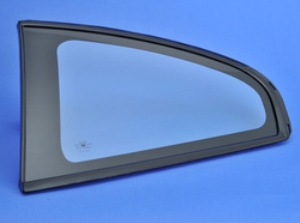

The commercial applications of the compounds include consumer products such as toys and footwear; medical tubing, collection bags and masks; and automotive window seals, instrument panel skins and interior and exterior trim. The company continues to develop solutions for other applications, such as wire and cable jacketing and blood bags. Teknor Apex’s BioVinyl compounds have already been chosen for certain commercial applications, including a new line of Flooring Adventures’ Tuff-Seal interlocking floor tiles; a series of shoe welting produced by Barbour Plastics; and a range of fashionable ‘flip-flop’ sandals manufactured by Okabashi Brands.

Source:www.teknorapex.com/