Contourx-100光学专长仪已设定了一个新的基准,以便以一流的价格点确切且可重复的非接触表面计量。

The compact footprint system provides uncompromised 2D/3D high-resolution measurement abilities in a simplified package that integrates several years of proprietary Bruker white light interferometry (WLI) innovation.

Next-generation improvements include a new 5 MP camera and updated stage for bigger stitching abilities, and a new measurement mode, USI, for even bigger convenience and flexibility for accuracy in thick films, machined surfaces, and tribology applications. Users will not be able to find a benchtop system with improved value compared to the ContourX-100.

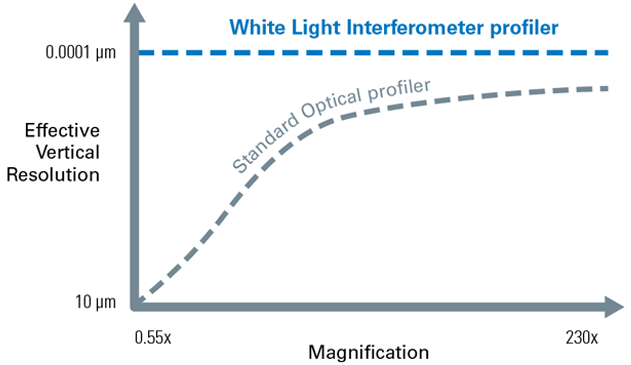

行业最佳Z解决方案

提供恒定的精确测量,与放大倍数无关。

用户友好的软件接口

Offers intuitive access to a wide library of pre-programmed filters and analyses.

Unmatched Metrology Value

Offers a simplified design without compromised measurement abilities.

特征

Unparalleled Metrology

The ContourX-100 profiler is known to be the culmination of more than 40 years of proprietary optical innovation and industry leadership in non-contact surface metrology, characterization, and imaging.

The system makes use of 3D WLI and 2D imaging technology for several analyses in an independent acquisition. ContourX-100 is strong in all surface situations ranging from 0.05% to 100% reflectivity.

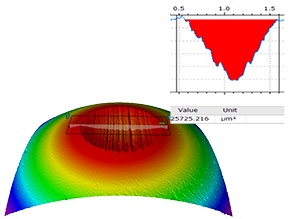

WLI offers constant and ultimate vertical resolution for all objectives. Image Credit:Bruker Daltonics

Unmatched Value and Analysis

With the availability of thousands of tailored analyses and Bruker’s simple and strong VisionXpress™ and Vision64®user interfaces, the ContourX-100 benchtop has been improved for productivity in both laboratories and on factory floors.

硬件和软件倾向于集成,以简化地访问顶级高通量光学性能,从而完全卓越可比的计量技术。

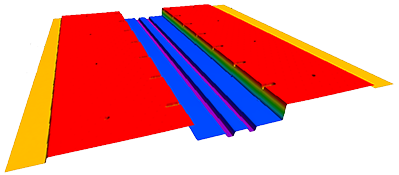

ContourX-100 manual stage. Image Credit:Bruker Daltonics

申请

具有特定溶液的表面无关计量

精密工程

Users can hold the surface texture and geometric dimensions of precision-engineered parts within the strict specification limits. The gage-capable measurement systems offer effective feedback and reporting as users tend to monitor, track, and calculate processes and assess GD&T conformance.

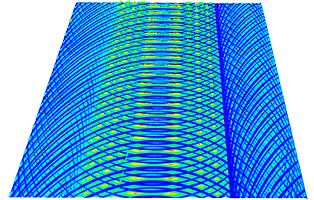

Image Credit: Bruker Daltonics

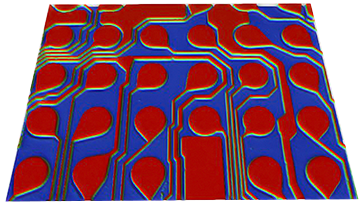

MEMS and Sensors

High-throughput and highly repeatable etch depth, film thickness, step height, and surface roughness measurements can be performed by the users, as well as sophisticated critical dimension metrology of MEMS and optical MEMS.

Optical profiling has the potential to characterize devices across the manufacturing process from wafer to final test, and even via transparent packaging.

Image Credit: Bruker Daltonics

Orthopedics/Ophthalmics

用户可以通过完整的产品生命周期实现对植入物材料和组件的准确测量。亚博网站下载WLI光学剖道剂AID QA,R&D和QC分析。

This can be done for applications varying from the characterization of surface parameters of lens and injection molds to surface finish verification and wear of medical equipment.

Image Credit: Bruker Daltonics

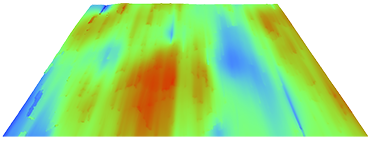

Tribology

用户有可能量化,分析和调节磨损,摩擦,润滑和腐蚀对材料或组件性能和寿命的影响。他们还可以识别定量磨损参数,并在光滑,闪亮或粗糙的表面上进行快速通过或进行快速通过检查。

Image Credit: Bruker Daltonics

Semiconductors

Users can improve productivity and decrease costs for both front- and back-end manufacturing processes with the help of automated, non-contact, wafer-scale metrology systems.

执行CMP后的固定性检查;共同性,凸起高度以及缺陷识别和分析;并量化组件结构的重要维度。

Image Credit: Bruker Daltonics

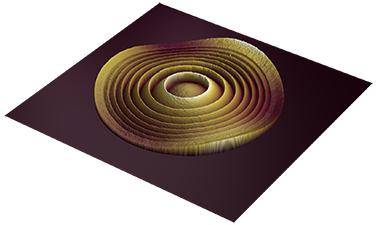

Optics

Users can gain better insights into the root causes of defects and improve polishing and finishing processes with precise and repeatable sub-nm roughness measurements.

The non-contact metrology systems allow compliance with growing stringent specifications and ISO norms for samples varying from small aspheric and free-form optics, to optical components with complicated geometries, to diffraction gratings and microlenses.

Image Credit: Bruker Daltonics