新的Zeiss Crossbeam的Laserfib使用飞秒激光器进行超快的材料处理大型样品。可以在10 µm至1毫米或更高的刻度上制造样品。可以通过像SIC这样的坚韧材料(如SIC)进行深层横截面,并直接披露感兴趣的结构。亚博网站下载

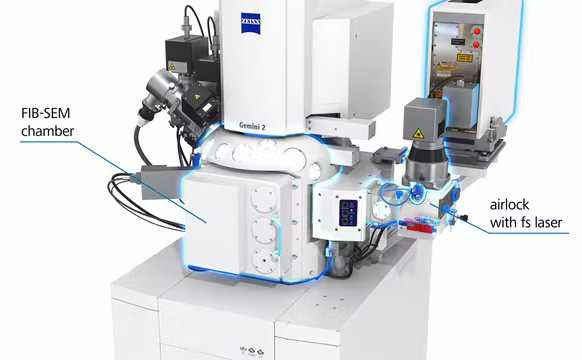

While executing laser milling, users will easily evade contamination of their FIB-SEM as the laser has been fixed to a steadfast chamber that is isolated from the primary instrument chamber.

在新的Laserfib的Zeiss Crossbeam的帮助下,用户可以从:

-

Huge material removal: Make extremely big cross-sections, going up to millimeters in width and depth, within a few minutes (up to 15 mio. µm³/s)

-

最小的损害:由于超短激光脉冲(飞秒激光)在坚定的腔室中,损坏和受热区域保持很小 - 仪器中没有任何污染

-

Integrating laser and FIB: Gain quick access to deeply buried structures for concentrated ion beam scanning electron microscope (FIB-SEM) analysis and additional FIB machining

Image Credit: Carl Zeiss Microscopy GmbH

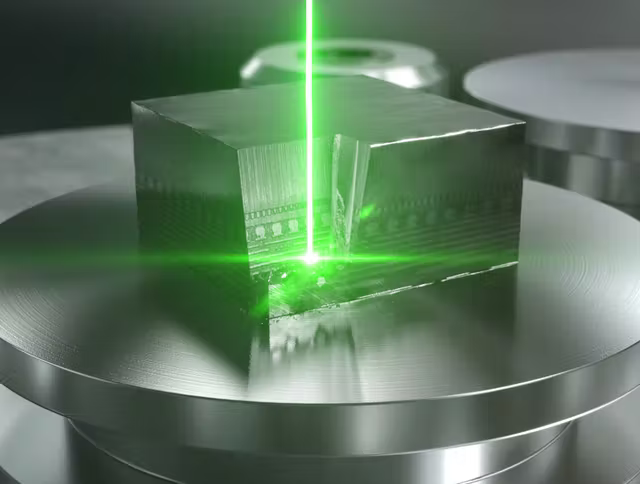

Massive Material Removal

在更少的时间内准备较大的样本

The new LaserFIB for ZEISS Crossbeam is the perfect tool to make extremely huge cross-sections ranging up to millimeters in-depth and width within minutes. As a result of the ultrashort pulse duration of the femtosecond laser, LaserFIB achieves the greatest removal rates of up to 15 mio. µm³ per second.

Such high ablation rates are perfect to make samples for additional FIB machining with ZEISS Crossbeam, complementing LaserFIB with the greatest accuracy at an even smaller scale (100 nm to a few 10 µm).

Image Credit: Carl Zeiss Microscopy GmbH

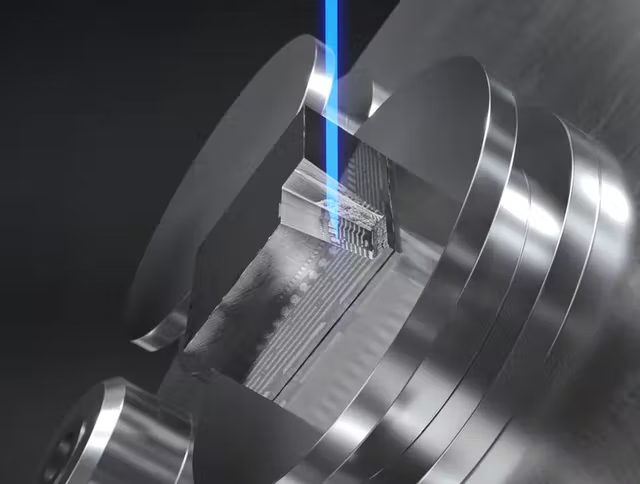

Combining Laser and FIB

Reveal All Structural Details

披露直接隐藏在表面下方的区域,从而在广泛的材料类型中披露了所有结构细节。如果是硬或软材料,则导电或绝缘材料:Laserfib机器以无与伦比的速度进行样品。

申请include the making of titanium alloy pillars for micromechanical testing or cube making in tungsten carbide.

在激光处理之前,用户可以将其FIB-SEM参考图像与3D数据相关联,例如X射线显微镜数据。激光处理后,将样品返回到主要的FIB-SEM腔室进行分析。执行最终的FIB抛光,以披露更多细节。

Image Credit: Carl Zeiss Microscopy GmbH

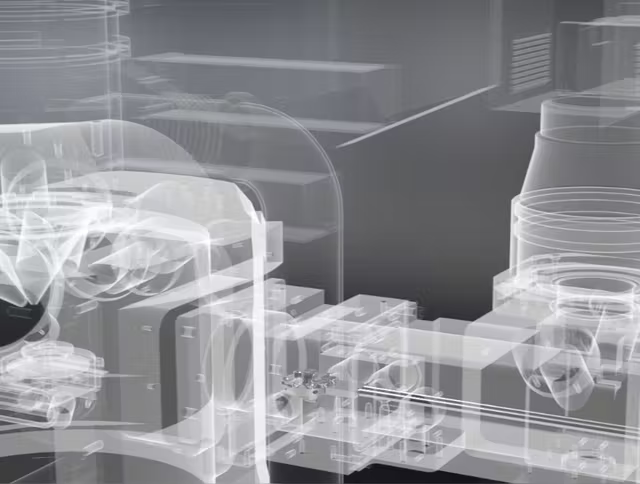

Minimal Damage

Conduct Quasi-Athermal Ablation

As a result of ultrashort laser pulses (femtosecond laser), LaserFIB leads to quasi-athermal ablation, thereby decreasing sample damage and keeping heat-affected zones to the minimum.

The laser work is performed in a dedicated chamber to prevent contamination and to allow safe and simple sample transfer between the laser chamber and the primary FIB-SEM chamber.

Image Credit: Carl Zeiss Microscopy GmbH