microPREP™ PRO is 3D-Micromac’s laser-based sample preparation system, offering smart sample preparation processes for a range of specimen-making applications. With the help of its combined ultrashort pulsed laser source, it complements the already present methods to sample preparation, including x-CT, ion beam processing, and microscopic analysis of any kind.

microPREP™ PRO can be used to generate samples of almost arbitrary shapes.Image Credit: 3D-Micromac AG

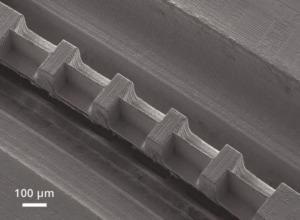

microPREP™ PRO provides specific sample geometries for in-plane TEM investigations and H-bars for cross-sectional analyses.Image Credit: 3D-Micromac AG

microPREP™ PRO can be operated as a lathe tool to prepare cylindrical samples with micrometer dimensions.Image Credit: 3D-Micromac AG

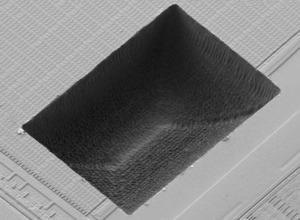

The high ablation rate of the laser can be used for time-efficient box milling as a starting point for FIB polishing.Image Credit: 3D-Micromac AG

microPREP™ PRO is ideal for ablating metals, ceramics, polymers, semiconductors, and compound materials. It makes new vistas for material and process development and failure analysis.

The CO₂ Snow Jet cleaning system removes debris broadly within seconds. Image Credit: 3D-Micromac AG

microPREP™ PRO is a compact tool for laser-based sample preparation on a micron level. Image Credit: 3D-Micromac AG

microPREP™ PRO's Custom Shape Import allows the creation of complex 3D-shaped samples. Image Credit: 3D-Micromac AG

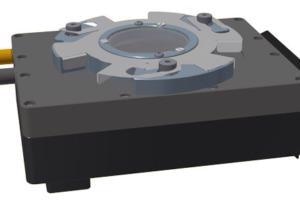

Motorized rotation stage: designed for continuous rotation in closed or open-loop mode. Image Credit: 3D-Micromac AG

Motorized Stage: For samples that are placed on a SEM stub/mount or directly on the platform. Image Credit: 3D-Micromac AG

Motorized Stage with Containment: For samples that need to be handled under special environment conditions. Image Credit: 3D-Micromac AG

Unique Workflows

3D-Micromac has come up with the latest workflows to address the particular needs of robust analytical methods. Hence, microPREP™ is ideal for users’ TEM, atom probe, SEM/FIB cross-sectional analysis, X-ray tomography, and micromechanical testing processes. Additionally, several patents guarantee competitive benefits for the users compared to present methods in the field of sample preparation.

Laser Technology

When there is enough power, laser radiation can ablate all types of materials. Furthermore, lasers can be placed accurately on a provided workpiece and directly focused utilizing standard optical elements. By utilizing ultra-short pulse lengths in the picosecond range, superficial surface heat influence from ablation is constricted to depths of a few microns or less.

Flexibility

The software's modular design offers high flexibility for a wide range of microstructure diagnostic and failure analysis methods. microPREP™ PRO enables users to make complex 3D shapes that allow extensive analysis of certain structures depending on generic patterns or imported CAD files.

Handling

With the availability of microPREP™ PRO, samples are simple to handle and can be moved to follow-up processes safely as microPREP™ PRO works with standard specimen stubs and mounts.

Additionally, the combined overview and high-resolution process cameras guarantee sample preparation with micrometer precision. Furthermore, features like the motorized stages collectively with the intuitive software allow users to perform preparation tasks comfortably and in a very short period of time.

Clean Specimens

microPREP™ PRO provides a compressed air system to enable users to obtain good outcomes concerning specimen cleanliness and an ideal start for post-processing steps.

The machine can also be fitted with an optional CO₂ Snow Jet for improved cleaning performance. This contactless nonabrasive cleaning system helps eliminate debris broadly within a matter of seconds, so there are nearly no particles left. Cleaning with the CO₂ Snow Jet implies no chemical- or cross-contamination for the sample.

Highly Efficient

microPREP™ PRO considerably decreases time-to-sample. Furthermore, microPREP™ PRO ensures a greater utilization of other tools inside the analysis chain while maintaining low costs of ownership.