公司急切地期待引入自动化,以在其业务中进行特定的发展,例如降低成本并创造更高效,更安全的工作环境。

自动化可以应用于从测试实验室到生产线的许多不同过程。完全自动化的材料测试系统可用于测亚博网站下载试数百个标本而无需操作员,可以在一夜之间运行。

但是,这些系统并不总是所有测试实验室的最佳解决方案。许多实验室缺乏测试量,无法使全自动系统的投资回报率。或者,它们可能会进行组件测试,而不是测试通常与自动系统相关的材料优惠券。对于这些客户,半自动化的测试系统可能是其应用和预算的更好选择。

引入半自动XY阶段测试系统为实验室提供了许多好处:

- 更高的效率使操作员可以更有效地使用时间

- 增加的吞吐量减少了整体测试时间

- 增加的重复性导致更一致的测试设置

- Increased safety and ergonomics for operators

AT2自动XY阶段吞吐量和效率

Video Credit: Instron - Europe

吞吐量

吞吐量是测试实验室中的关键指标之一。实验室生成的数据对于公司的整体成功至关重要;结果可以在产品开发项目中实施,也可以在产品退出生产线时验证产品质量。测试的延迟可能会对重要公司目标产生不利影响,例如新产品或分销截止日期的上市时间。

The time it takes to run an actual test is fixed, whether the system is automated or manual. Test time is often controlled by international standards such as ISO, ASTM, and EN standards, or by internal company test procedures.

该过程的一部分可能导致整体测试时间显着增加,这是测试对测试之间发生的步骤。

First, the tested specimen must be removed, and it should be checked that no remnants are left behind. Then the operator must set up the next specimen carefully, making sure it is correctly positioned and aligned. This process will take time, which can vary depending on how complex the test is as well as the user’s experience.

这些是半自动化系统可以为实验室吞吐量做出重大贡献的领域 - 测试之间的时间。

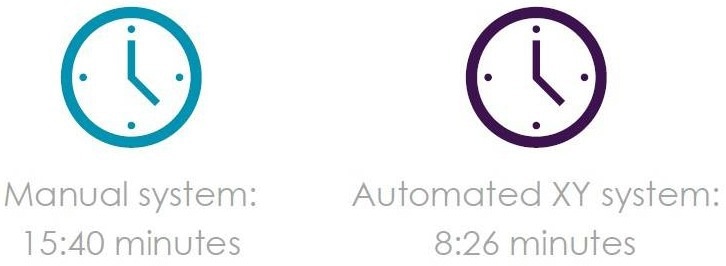

一个例子XY stage可以改善吞吐量是评估来自手术工具中使用的弹簧的基准测试的数据。手动运行了五十个标本,花了近16分钟。

The operator-led tests were run one immediately after another, with no breaks or diversions. Typically, an operator who is running tests manually has regular interruptions, such as breaks, meetings, or conversations with colleagues, where testing is put on hold.

Image Credit: Instron - Europe

使用半自动化的XY系统,相同的五十个测试仅需大约8.5分钟。XY系统使得可以在相同时间内测试46%的样本。这个额外的时间可以使整个过程的几个领域受益,例如上市时间,打击工程项目里程碑或发布产品进行分销。

Image Credit: Instron - Europe

Customers using an XY system can optimize throughput even further by having several test fixtures available.

While one batch of specimens is being tested, the operator is able to prepare the next batch by placing all the specimens to be tested into the fixture. This reduces downtime between tests significantly, as the operator can set up a new sample on the XY system quickly and then immediately press start.

积压也可以更有效地进行,从而更快地在研发项目和生产线所需的数据上进行周转速度。

Efficiency

尽管XY阶段增强了实验室吞吐量,但它还通过给操作员有更多时间执行其他任务来提高效率。自动化的使用意味着操作员可以自由离开系统并执行其他增值任务,例如完成测试报告,数据分析或测量和准备下一批测试标本。

The benchmark data from the spring tests demonstrates that in addition to boosting the lab throughput by 46% during an 8-hour shift, the operator will theoretically have an additional 3.5 hours of time that would otherwise be consumed when manually running tests. These 3.5 hours is time that can be used much more efficiently.

Repeatability

有许多因素对可重复性产生影响。标本放置至关重要:如果标本不正确对齐或与加载线相比,则角度为一定角度,则将导致结果的变化。

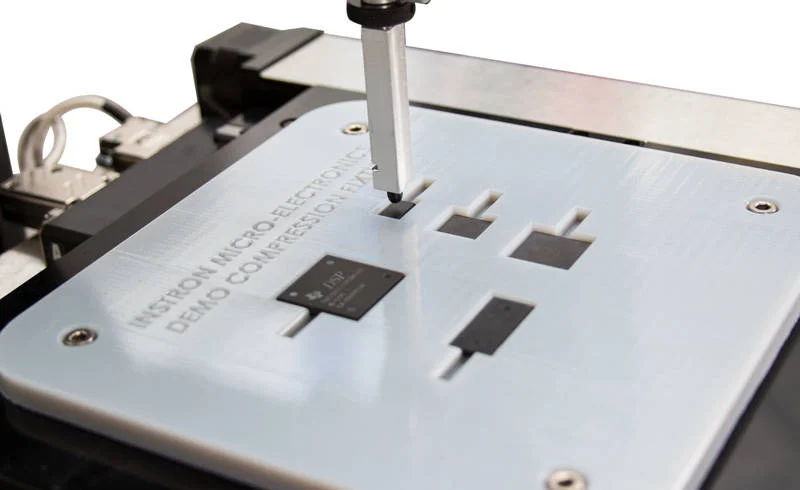

尽管有一些工具可以帮助标本对齐,但在这一领域仍至关重要的操作员经验仍然至关重要,并且必须花时间和护理来准备标本。XY阶段的能力可以定位测试组件或具有增强性能的样品。

Image Credit: Instron - Europe

When specimens are inserted and manually aligned, the operator’s influence on the test results can be particularly noticeable when multiple operators with different levels of experience are running tests on several systems or even across multiple labs. This is compounded when testing numerous points on small components.

上图中显示的集成芯片非常小。确保这些零件在中心进行适当测试,并且在边缘周围相同的4点处于手动准备样品时可能是一个挑战。

An XY system with a well-designed fixture can circumvent such challenges relative to specimen placement and consistency of test locations. An XY stage supplies repeatable test locations from sample to sample, ensuring that the generated data is comparable.

安全

According to OSHA evaluations, companies in the U.S. pay around $1 billion in direct worker compensation each week, which does not include additional costs related to disturbances in the lab.

If an operator is away on medical leave, the lab’s throughput will likely be reduced due to less staff. If the injured operator knows how to run a specific system or test, that loss of expertise will impact the lab’s capacity to meet its customers’ requirements. Also, lab accidents can have a negative impact on user confidence when operating the equipment.

使用XY系统时,减少对操作员交互的需求可以提高安全性,因为操作员的手很少需要进入测试空间。它还提供了改进的人体工程学,因为它消除了手动加载样品时所需的重复运动。

使用XY system意味着可以删除围绕样品对准和测试点的一些测试挑战;因此,可以更有效地对经验较少的运营商进行培训,从而使系统更易于使用。此外,在运行系统时,这些操作员将更加自信,从而减少实验室的整体破坏。

概括

半自动化系统(例如XY阶段)可以提供实验室,其中全自动系统不是最好的解决方案,这是一系列好处 - 吞吐量,效率,可重复性和安全性。

XY阶段使测试实验室能够以较小的规模引入自动化,该自动化非常适合多种不同的应用,包括医疗设备,例如小瓶和注射器,以及电子设备和组件。

此信息已从Instron -Europe提供的材料中采购,审查和改编。亚博网站下载

有关此消息来源的更多信息,请访问乐器 - 欧洲。