穿过GydF4y2Baacademia and industry,GGydF4y2Ba在场GydF4y2Bathe opportunity for a varied andrich field of study.我GydF4y2Ba不利GydF4y2BalGydF4y2Baarge window glass becomes更多GydF4y2Ba功能,而新型的微加工技术正在推动微型化GydF4y2Ba达到极限GydF4y2Ba。Many questions remainopen, however, ranging fromthe basics of玻璃物理学GydF4y2Balimiting现实世界应用的脆性。GydF4y2Ba

为了实现设计和加工玻璃的更科学驱动的方法,该行业必须将基础奠定基础,以原子重排,缺陷启动和动态断裂作为对机械负荷的反应。GydF4y2Ba

在本文中,我们提供了与最新创新有关的观点GydF4y2Bamicro-mechanical testing of glasses以及他们如何帮助研究人员并帮助更好地理解和改善玻璃组件的性能。GydF4y2Ba

微型玻璃组件GydF4y2Ba

自从玻璃生产本身开始以来,确保玻璃的强度足以适应给定的任务。一个关键问题是,玻璃的实际强度始终低于化学键强度所推论的理论强度。GydF4y2Ba

其主要原因是微观缺陷GydF4y2Bathat act as stress concentrators。这样的缺陷是制造和整理过程的结果,难以避免。GydF4y2Ba

简而言之,他们在整个玻璃网络上揭示了弱环节。这已经在1920年代确定,当时格里菲斯观察到玻璃的强度取决于测试样品的大小。GydF4y2Ba1GydF4y2Ba

这种缺陷的可能性随着样本的体积而降低。因此,随着玻璃成分的尺寸较小,玻璃成分变得相对强大和强大。GydF4y2Ba

这种宽大的力量呈现的机会众多,具有巨大的含义。当然,大大减少玻璃的大小并不总是可行的策略,例如建筑物的窗户。GydF4y2Ba

取而代之的是,复合眼镜的应用提供了一种备受改善的解决方案,以围绕土木工程应用中固有的玻璃杯固有性。在大小方面的进步可以应用于高科技玻璃组件的小型化,直至纳米尺度,在那里,格里菲斯(Griffiths)的理论现在已经获得了新的重要性。GydF4y2Ba

Recently, progress in micro-additive manufacturing (µAM) and laser-assisted etching techniques has facilitated efficient and precise microfabrication of sophisticated glass components.2-4

此类眼镜的可定制性能与其非凡的化学和热稳定性相结合,揭示了许多新的技术应用,包括微电子,医疗技术,数据存储,微电力学系统,微能力和微摩托技术。GydF4y2Ba

现在,了解和预测玻璃的确切微型机械行为的能力现在是一项重要任务。GydF4y2Ba

微观和纳米级的玻璃力学GydF4y2Ba

随着制造方法的进度和微型玻璃组件的应用,重新评估其机械性能绝对至关重要。GydF4y2Ba

As the mechanical properties at newly attainable small length scales typially exceed列出的批量特性,GydF4y2Baa considerable opportunity is now open.

Not only is there a potential increase in yield strengths, but approaching the intrinsic properties of glasses also reveals phenomena such as micro-ductility of glasses that would otherwise be brittle.

我n the attempt to reduce the brittleness of bulk-sized glasses, investigations into micro-ductility can, for instance, serve as a stepping-stone towards the production of truly ductile glasses.

实践中的微力测试GydF4y2Ba

Pioneering advances in the field of in-SEM nanoindentation, Alemnis can offer a large range of time-tested micromechanical testing equipment. The Alemnis Standard Assembly (ASA) is the cornerstone of its modular system.

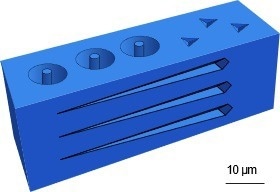

The three fundamental test types of micromechanical geometries that are made possible with the ASA are uniaxial compression or tension, nanoindentation, and lateral scratch testing (Figure 1).

图1。GydF4y2Ba微力学测试的样品几何形状:微柱,纳米装饰和刮擦测试痕迹的示意图。图片来源:Alemnis AGGydF4y2Ba

这些几何形状都可以用作大量重大研究的基础。可以使用此类测试进行评估的常规特性是硬度和弹性模量,断裂韧性,产量强度等。GydF4y2Ba

Add-ons for the ASA can also help evaluate the effects of extreme temperatures ranging from -150 °C up to 1000 °C, strain rates ranging from 0.001sGydF4y2Ba-1up to 10’000 s-1,不同的气氛,湿度和液体。GydF4y2Ba

This unparalleled versatility in terms of testing conditions pushes the limits of what is possible when it comes acquiring an understanding of materials under real-world operating conditions.

图2。GydF4y2Ba: Fracture toughness of oxide glass measurement by nanoindentation.图片来源:Alemnis AGGydF4y2Ba

实际上,在千分尺尺度上调查机械性能要求对稳定性和定位进行无与伦比的精确控制GydF4y2Bain situ通常在扫描电子显微镜(SEM)中发现的测试。GydF4y2Ba

Testing inside an SEM offers unmatched imaging capabilities. However,the vacuum environment of an SEM prevents any effects of environmental fatigue. Environmental humidity is known to provoke stress corrosion cracking by catalyzing bond breakage in propagating cracks. Therefore, there are also a number of good reasons to conduct micromechanical tests前态GydF4y2Ba-GydF4y2Ba在空中。GydF4y2Ba

极端条件测试GydF4y2Ba

缩小玻璃促进了材料内在的机械性能的测试。但是,内在性的概念不仅限于室温和准静态应变率。温度和应变速率都是必须定义和控制的重要变量。对于玻璃科学,有许多亚博老虎机网登录关键的应用含义。GydF4y2Ba

首先,玻璃过渡温度周围的温度 - 涂鸦关系往往是非线性和不连续的。GydF4y2Ba5GydF4y2Ba结果,众所周知,在玻璃微型组件的温度升高时的工作极限很难预测。其次,无定形原子结构的变形过程可能对应变速率的变化极为敏感。GydF4y2Ba6GydF4y2Ba

Figure 3:Strain rate dependent micro compression of fused silica6GydF4y2Ba。图片来源:Alemnis AGGydF4y2Ba

我t is important to tabulate micromechanical properties under such conditions, for component design, life-time prediction, and other engeneering tasks. Moreover, as these properties evolve as a function of temperature or strain rate (or both), they are also characteristic of atomic-scale deformation mechanisms that are not directly observable.

例如,可以根据激活能量,激活量和应变率敏感性评估此类数据。GydF4y2Ba

极端微机械测试不仅提供基本工程量。这是一种科学方法,使玻璃科学家能够仔细评估无定形材料中变形的基本过程,由于缺乏结晶性,因此很难研究。亚博网站下载GydF4y2Ba

Figure 4.通常在600°C下脆性熔融二氧化硅的延长微透明度(0.5 TGydF4y2BaGGydF4y2Ba).5GydF4y2Ba图片来源:Alemnis AGGydF4y2Ba

参考:GydF4y2Ba

- A. A. Griffith,‘vi。固体中的破裂和流动现象,GydF4y2Ba哲学反式。R. Soc。伦敦。ser。包含。帕普。数学。物理。特点GydF4y2Ba,卷。221,不。582–593,第163–198页,1921年1月,doi:10.1098/rsta.1921.0006。GydF4y2Ba

- F. KotzGydF4y2Ba等。GydF4y2Ba, ‘Three-dimensional printing of transparent fused silica glass’,自然GydF4y2Ba,卷。544,没有。7650,第337–339页,2017年4月,doi:10.1038/nature22061。GydF4y2Ba

- X. WenGydF4y2Ba等。GydF4y2Ba,“带有纳米级分辨率的3D打印二氧化硅”,GydF4y2Ba纳特。母校。GydF4y2Ba,卷。20,否。11,第1506–1511页,2021年11月,doi:10.1038/s41563-021-01111111。GydF4y2Ba

- J. T. ToombsGydF4y2Ba等。GydF4y2Ba,“使用微观计算的轴向光刻的硅胶添加剂制造”,GydF4y2Ba亚博老虎机网登录,卷。376, no. 6590, pp. 308–312, Apr. 2022, doi: 10.1126/science.abm6459.

- R. N. Widmer等。GydF4y2Ba, ‘Temperature–dependent dynamic plasticity of micro-scale fused silica’,母校。des。GydF4y2Ba,卷。215,p。110503,2022年3月,doi:10.1016/j.matdes.2022.110503。GydF4y2Ba

- R. Ramachandramoorthy等。GydF4y2Ba,“显微镜玻璃的动态可塑性和失败:依赖性的延性 - 脆性 - 脱骨转变”,GydF4y2BaNano Lett。GydF4y2Ba,卷。19,不。4,第2350–2359页,2019年4月,doi:10.1021/acs.nanolett.8B05024。GydF4y2Ba

此信息已从Alemnis AG提供的材料中采购,审查和改编。亚博网站下载GydF4y2Ba

有关此消息来源的更多信息,请访问GydF4y2BaAlemnis Ag。GydF4y2Ba