Azom与福特汽车公司的Alan Banks谈到了在车辆中使用轻质材料来提高燃油效率和行业可持续性的重要性。亚博网站下载

请您介绍自己和您的专业背景吗?

我叫艾伦·班克斯(Alan Banks)。我是福特汽车公司的英国轻量级创新经理。我在福特工作了大约39年,我有一流的孟SC和MSC。我还担任英国复合材料的董事会主席,英国汽车委员会的轻量级战略小组主席,并主持Vehicular Composites领导力论坛。

How significant is the weight of a vehicle to fuel consumption, and how much can be saved by transitioning to more lightweight materials?

我的工作是基于我们的商用车,尽管燃油经济性是我们客户的重要推荐人,但我们将有效载荷效率和总拥有成本视为客户群的最大指标。当我们向零排放车辆过渡时,二氧化碳减少至关重要。

在该车辆在运行时间内不会产生二氧化碳的领域,我们需要意识到我们的嵌入式二氧化碳足迹。因此,制定了一个明确的计划,以实现可持续性并了解我们对客户的责任,而环境在我的日常生活中齐头并进。

Alongside your role as Lightweight Structures Supervisor at Ford Motor Company, you are also team leader of the Composite Lightweight Automotive Suspension System (CLASS) and Composite Hybrid Automotive Suspension System Innovative Structures (CHASSIS) projects. What are these projects, and what do you hope to achieve with them?

这些项目主要基于研究,以确定我们如何在大规模上部署高端轻质材料。亚博网站下载课堂项目使我们能够了解混合材料设计以及这些材料在制造和服务过程中如何相互作用。亚博网站下载该项目直接导致了底盘项目。这使3个主要结构悬浮构件的重量减少了46%以上(31.9公斤),并且仅使用了能够大规模生产的生产过程。

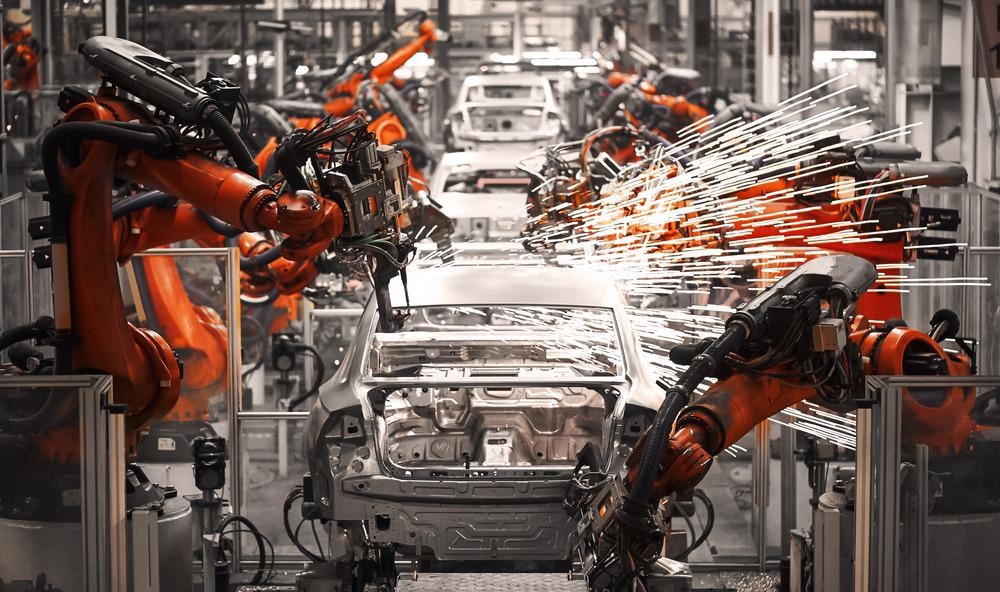

Image Credit: Jenson/Shutterstock.com

这些项目在我们未来的平台中启动的其他应用程序中发现了成功。我们学到的最重要的教训不是害怕如何处理混合材料。亚博网站下载通过将正确的材料放在正确的位置,我们可以可持续有效地满足客户的需求。

您能否描述一些轻巧的高级材料的例子,这些材料在现在和将来都可以在优化车辆性能方面产生重大影响?亚博网站下载

I think that the 'now' is more than adequately covered by the advances in aluminum processing and composite materials. However, we shouldn’t lose sight of steel. Steel is still going to be the material of choice for most OEMs due to its efficient cost/weight parameters. But steel is increasing in its research just as fast as the rest of the materials industry.

我谈到了正确位置的正确材料,尤其是钢制高强度钢的尤其如此。我相信,在轻质钢中提供具有1000MPA的材料的设计完全可行,可将其形成且可焊接,使重量减少多达25%。亚博网站下载另外,使用降低规格可能意味着成本中立。降低体重,提高性能并降低成本,而不会影响设计的回收和可持续性方面,这是双赢的胜利。另外,我们还允许单辆车携带更多有效载荷,从而减轻了世界自然资源的负担。这是我最大的重点,让我开始工作。

Image Credit: Alex Neshitoff/Shutterstock.com

In the future, I would say advancements in nanotechnology will be coming to the fore. Graphene and carbon nanotubes are not science fiction - they are science fact. Ford has had great success in infusing graphene in some of our underhood components in the past, and this should continue. Graphene is very expensive but because you use so little of it (less than 0.1% volume typically), it can have tremendous benefits in weight, NVH, durability, and potentially cost. Graphene also has the ability to be functionalized to allow sensors in some critical structures for preventative maintenance. This could pay dividends in an autonomous future.

What steps is Ford taking to manufacture and recycle these materials in a green way?

Ford was the first major EOM to publish a sustainability report. This is now published yearly and really showcases the great work that we are doing for the environment. Of course, we realize that building machines that burn CO2 seems contrary to that ideal – but mankind has become very used to having on-demand services and products. We only have to look at the recent pandemic to see how fragile our supply chain can be and so we see it as our responsibility to further our products to meet our customer's demands.

We have a purchasing demographic of the population who are more environmentally aware than ever before and they will demand that we take action. We could of course wait for legislation to make this happen, but at Ford we are taking a much more proactive approach. Even when the US pulled out of the Paris Climate Accord, Ford chose to stay in unilaterally – you will have seen our Chairman (Bill Ford) talking passionately about making Ford carbon neutral by 2050.

These aren’t just words – in Europe, we have committed to being all-in on electrification and we are aggressively pursuing this goal. And why? Because our customers demand it. As well as this, at the end of the life of our vehicles, we see the recycling, dismantling, and circularity of materials and components as a key step to developing better and robust solutions that will mean that nothing from a vehicle goes to landfill.

升级是我非常热衷于将废物变成有价值的商品的领域。我们在美国的团队最近与赖斯大学进行了一项研究,以从废物塑料中创建石墨烯,正是这种创新将帮助我们所有人推动循环可持续性。

在此处阅读我们对赖斯大学的研究人员的采访

You are participating in a talk at the高级材料显示在NE亚博网站下载C本月考虑运输轻巧如何更可持续和经济。您能描述您将要涵盖的一些要点吗?

Affordable lightweighting is about encompassing scalability while enhancing our sustainability credentials. It is incredibly important that we as an industry tackle these issues together. We all have the same issue, we live on the same planet, and we all use the same resources. Collaboration I think will be key to success, not only for Ford but for the global economy. This is not a test that anyone should fail. We all share the responsibility to succeed.

您能否描述实施轻质材料的努力与向汽车领域中大型电动汽车制造的转变之间的关系?亚博网站下载

Electric vehicles, like it or not, have added a huge amount of weight to our vehicles. More weight means more natural resources being used. This is bad enough for passenger cars, but for commercial vehicles, this detracts from payload efficiency. When people's diving licenses are restricted to 3.5T for a Cat B license, this means a restricted payload and therefore more vehicles on the road using even more resources to manufacture. This isn’t a sustainable scenario.

Whilst it's true that in Britain and the EU there is a driving license derogation up to 4.25T for electric vehicles, this is goods carrying vehicles only and is due to run out in 2023. Lotus founder Colin Chapman had a motto where he said ‘Just add Lightness’. This is a phrase on every email I send and I want people to have it in the forefront of their minds when they design their components.

会议有多重要高级材料亚博网站下载为了建立对话并引起对高级和轻质材料研究的兴趣吗?亚博网站下载

These events are where the real networking and collaborations take place. Whilst we coped virtually during the pandemic, I think everyone would agree that there is no substitute for face-to-face collaborations and networking. You get out of these events what you put in, and I am very excited to meet everyone.

About Alan Banks

Alan Banks is the Lightweight Structures Manager at Ford Motor Company. He started work at Ford in 1983 as an apprentice and his remit is to lead projects with light-weighting technologies and applications in design with mass production capability.

Alan Banks is the Lightweight Structures Manager at Ford Motor Company. He started work at Ford in 1983 as an apprentice and his remit is to lead projects with light-weighting technologies and applications in design with mass production capability.

他领导了复合轻型汽车悬架系统(类)项目,该项目赢得了2018年JEC世界汽车应用创新奖和复合英国创新奖奖的复合综合汽车悬架系统创新结构(Chassis)项目。

Alan has a First-Class Honours Degree and an MSc from the University of Bradford, is a Fellow and Chartered Engineer with the Institute of Engineering Technology and a Fellow of the Institute of Innovation and Knowledge Exchange, and a member of the Society of Automotive Engineers. He is Chairman of the Board for the Composites UK Trade Association, Chairman of the Vehicular Composites Group and the Chairs the Lightweighting UK Auto Council Strategy Group.

https://www.sae.org/publications/technical-papers/content/2022-01-0341/

https://www.sae.org/publications/technical-papers/content/2020-01-0777/

https://www.sae.org/publications/technical-papers/content/2019-01-1122/

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the条款和条件of use of this website.