AZoM speaks with Sung Hoon Kang fromJohns Hopkins Universityabout his research into a material that protects like metal upon impact but is lighter and tougher than metal. This novel foam-like substance could bea potential game-changer for helmets, body armor, and automobile and aerospace parts。

Energy-absorbing materials are used in many daily and advanced applications for vibration isolation and impact protection. What inspired your research into investigating the energy absorption capacity of liquid crystal elastomers (LCEs)?

We had observed that the standard materials for protective devices were heavy, unable to perform well with high-speed impacts and were not reusable. Thus, we decided to try and improve their energy absorption capacity from high-speed impacts while also increasing reusability and reducing weight.

We focused on liquid crystal elastomers (LCEs), as they have ideal characteristics for this application. They are softer than typical elastomers under static conditions while transforming into hard, shock-absorbing plastics upon high-speed impact.

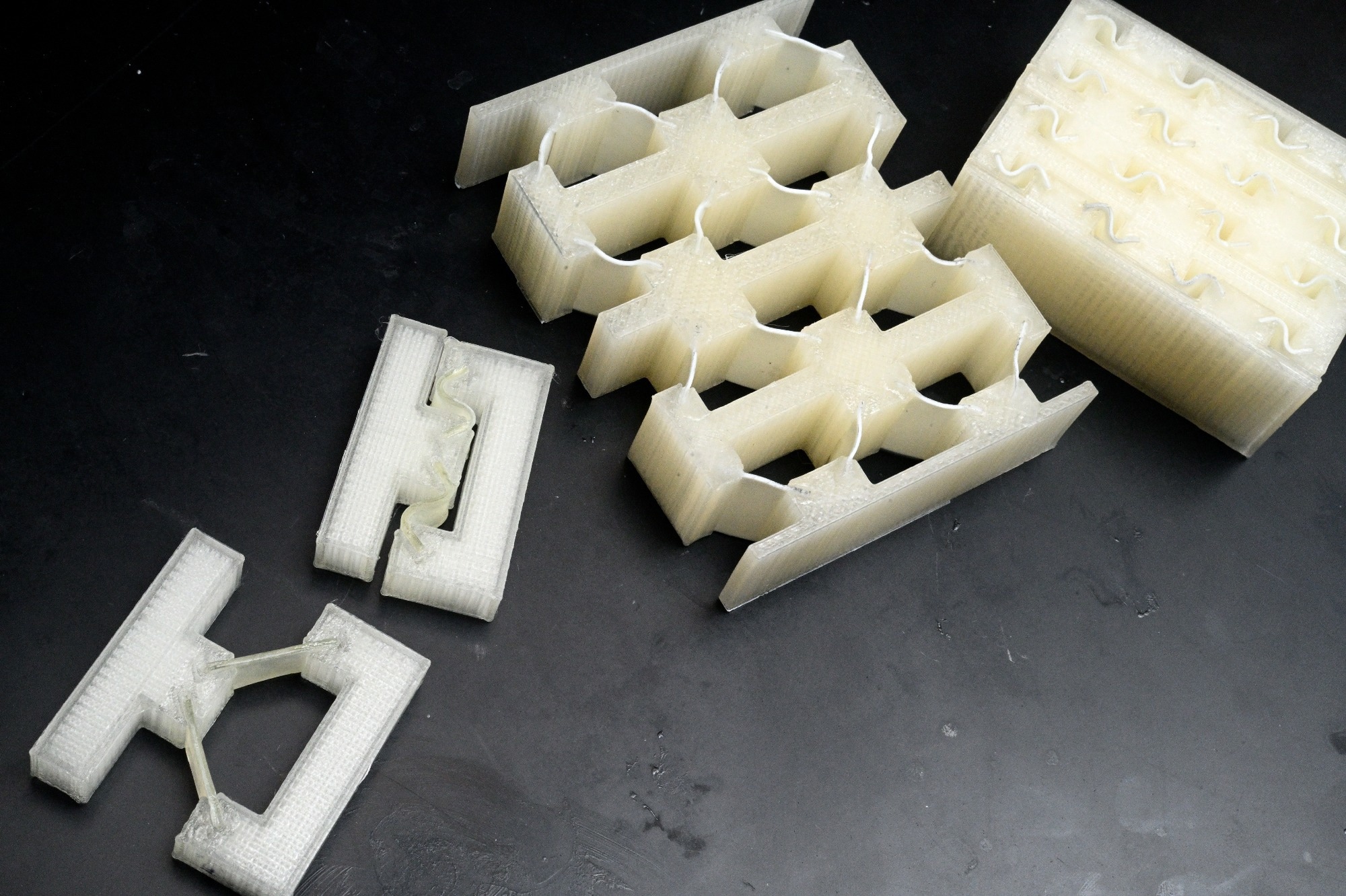

Image Credit: Johns Hopkins University

What are high energy-absorbing LCEs, and how do they absorb energy?

与常规弹性体相比,液晶弹性体(LCE)高度耗散。非凡的耗散行为来自聚合物网络粘弹性变形的独特耦合以及液晶成分(介质)的重新定位。在这里,将材料排列成亚博网站下载多层结构,这些结构被重复以扩大能量吸收能力。引入类似泡沫的几何形状并沿载荷方向堆叠它们,使我们能够在材料和几何形状之间具有协同作用,从而达到了与散装材料相比,获得更高的能量吸收密度(=每体积能量吸收)。材料的粘弹性耗散与结构的快速屈曲之间的这种协同相互作用也导致能量吸收密度随着堆叠层的数量而增加。

What are some of the problems associated with these materials as they exist today?

Currently, there are challenges associated with the synthesis and manufacturing of LCEs. Our current LCE synthesis protocol takes several days and our manufacturing approach is not suitable for a large number of stacked foams. So, we need new approaches for the synthesis and manufacturing of LCEs to address the issues.

您能概述如何创建改进的LCE吗?

我们通过设计类似泡沫的多层结构来利用LCE的能量耗散能力,从而扩大撞击时能量耗散密度。结构包括夹在刚性支撑之间的倾斜LCE梁的重复单元。通过使LCE单元彼此堆叠来制造多层几何形状。

What advantages are conferred by changing the degree of mesogen alignment and the loading direction relative to the director?

The energy absorption density of architected LCE can be improved by changing the degree of mesogen alignment and the loading direction relative to the director compared to a non-aligned case.

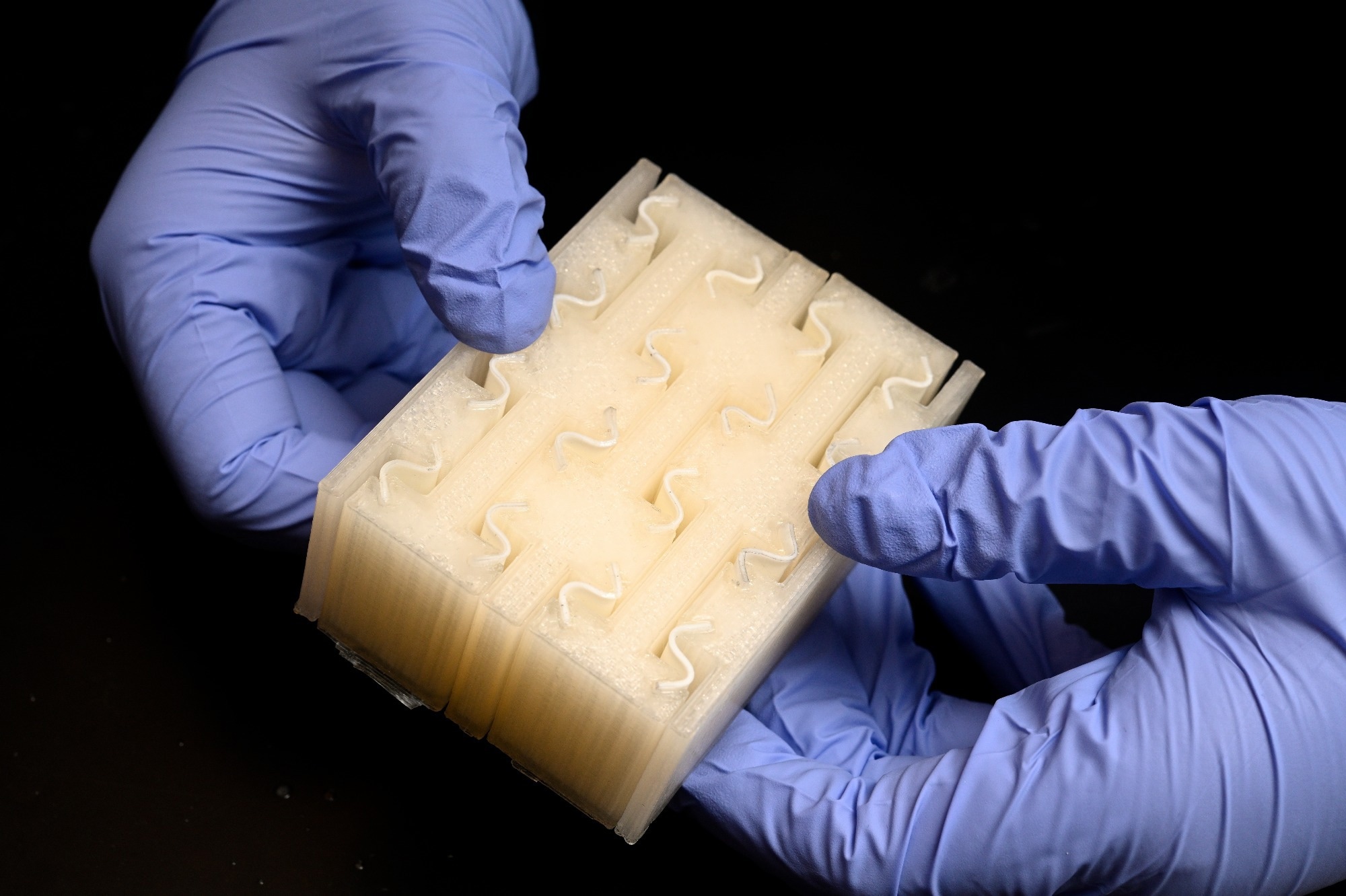

Image Credit: Johns Hopkins University

How did you go about testing the efficacy of this material, and how did it compare to existing alternatives?

We tested the efficacy of our material by measuring energy absorption density at a wide range of strain rates (i.e., speed) using three different machines as no single machine can cover the range. For a strain rate of 600 s−1, the foam-like unit exhibited up to a 5 MJ m−3energy absorption density, which is over two orders of magnitude higher than the same structure tested at a low strain rate (6✕10-3s-1)。

We compared the performance of our material with existing alternatives and found that our material has orders of magnitude higher energy absorption density than existing foams with a similar density and has comparable performance to that of metals at impact condition, which are irreversible and have one to two orders of higher density.

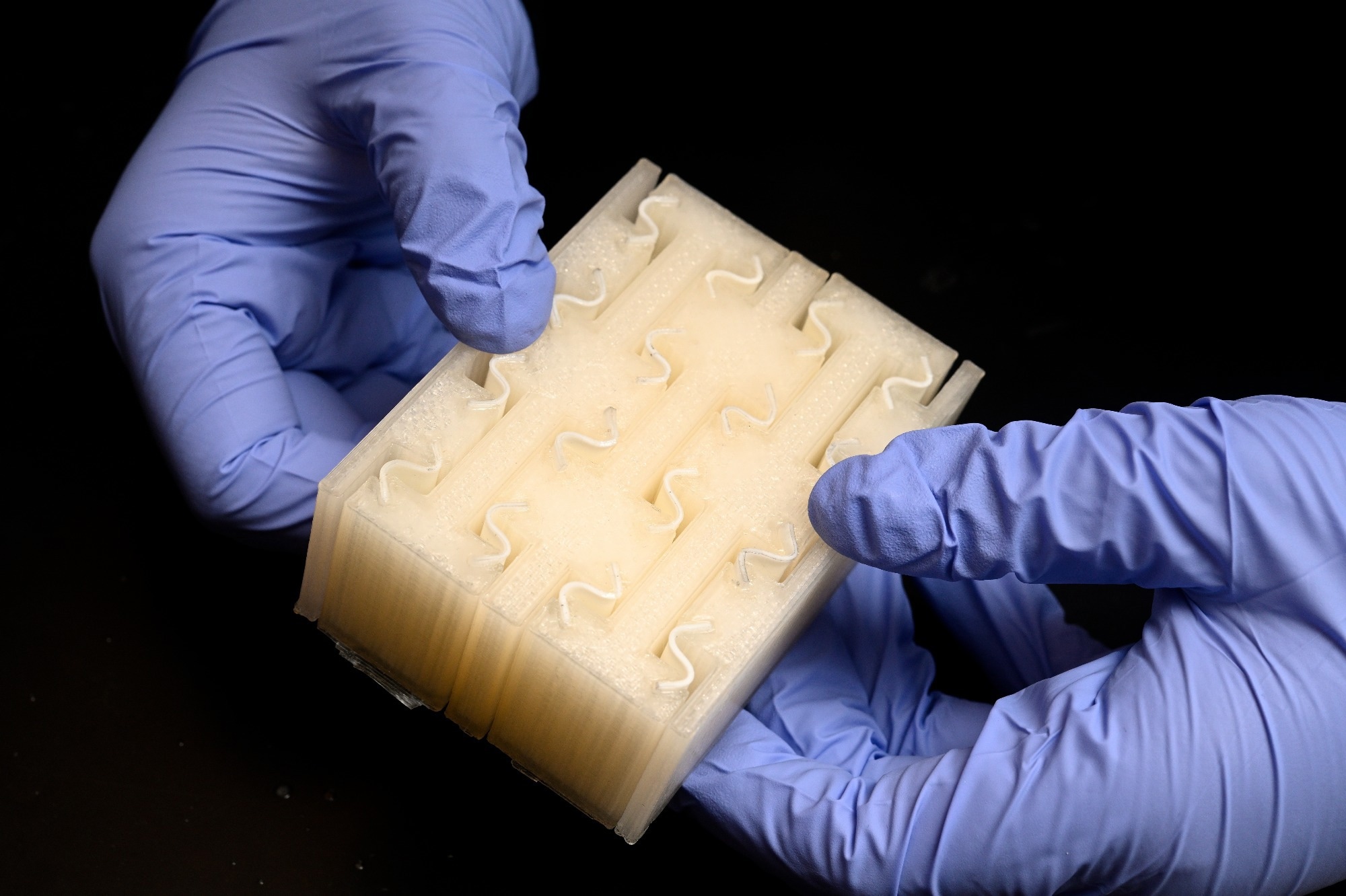

Image Credit: Johns Hopkins University

What couldn’t you test, and how do you intend to address this in the future?

实验表明,该材料能够承受重约4至15磅的物体的打击,以每小时约22英里的速度速度。由于我们学校的测试机的限制,测试限制为每小时22英里,但我们相信我们的材料可以安全地吸收更大的影响。将来,我们希望找到具有更高测试速度能力的机器来解决此问题。

What are the potential applications of this novel material, and what industries would benefit from it the most?

The potential applications include helmets, body armors and shock/vibration absorbers for vehicles and aircraft. The new material can be attractive to industries where reusable and lightweight energy absorption capability is desirable such as the automotive, aerospace, and sports equipment industry.

What hurdles stand in the way of mass marketing this material — for example, can its production be scaled up?

对于这种材料的大规模营销,我们需要优化设计和处理,因为该材料的当前形式不适合大规模生产。

What kind of partnerships are you looking for to potentially distribute your material?

We are looking for partnerships with industries to design, fabricate, and test next-generation reusable lightweight energy-absorbing materials tailored for specific applications.

在您最初的研究成功之后,您的研究下一步是什么,and what partners do you hope will accompany you on this journey?

在我们的初步研究中,我们将LCE制成的光束用于简单的一维元结构。未来通过系统的结构设计预期,预期能够吸收能量的增强。我们希望与研究机器学习的研究人员合作,以优化设计以更好地吸收能量。我们还评估了提高材料强度和能量吸收能力的其他机制。我们希望与研究材料化学和处理这一旅程的研究人员合作。

What else can our readers expect to see regarding shock-absorbing materials in the coming years?

在接下来的几年中,可能会取得与消除材料开发的各个方面有关的进展。亚博网站下载例如,根据测量数据,具有更好的冲击吸收吸收的材料的合成以及可以衡量影响能量的多功能材料的材料的合成,可用于控制材料的微观结构,以改善冲击吸收性能,亚博网站下载以及新材料的可扩展制造方法。亚博网站下载

About Sung Hoon Kang

Sung Hoon Kang是Johns Hopkins University的Hopkins Extreme Material Institute机械工程系的助理教授和纳米型技术研究所。亚博网站下载他获得了博士学位。哈佛大学和M.S.应用物理学学位和B.S.分别获得麻省理工学院和亚博网站下载首尔国立亚博老虎机网登录大学材料科学与工程学位。Sung Hoon一直在调查解决方案,以应对包括弹性,感应,能源和医疗保健在内的应用程序材料,结构和设备中当前挑战。亚博网站下载特别是,他根据力学和物理学原理和工具(例如数值建模,3D打印,3D结构/材料/机械特征)以及工具的原理研究材料和结构的合亚博网站下载成和制造。体外/in vivotesting.

Sung Hoon Kang是Johns Hopkins University的Hopkins Extreme Material Institute机械工程系的助理教授和纳米型技术研究所。亚博网站下载他获得了博士学位。哈佛大学和M.S.应用物理学学位和B.S.分别获得麻省理工学院和亚博网站下载首尔国立亚博老虎机网登录大学材料科学与工程学位。Sung Hoon一直在调查解决方案,以应对包括弹性,感应,能源和医疗保健在内的应用程序材料,结构和设备中当前挑战。亚博网站下载特别是,他根据力学和物理学原理和工具(例如数值建模,3D打印,3D结构/材料/机械特征)以及工具的原理研究材料和结构的合亚博网站下载成和制造。体外/in vivotesting.

His research has been supported by AFOSR, NSF, NIH, ARO, ONR, State of Maryland, and private foundations. Throughout his career, Sung Hoon has co-authored 57 papers, has given ~170 presentations (including ~100 invited talks), and has six patents and five pending patents. His honors include Invitee for 2022 US-Africa Frontiers of Science, Engineering, and Medicine Symposium, the 2022 Hanwha Non-Tenured Faculty Award, 2021, 2020 Air Force Summer Faculty Fellowship, 2020 Johns Hopkins University Catalyst Award, 2019 Johns Hopkins University Whiting School of Engineering Research Lab Excellence Award, Invitee for 2019 China-America Frontiers of Engineering Symposium, FY 2018 Air Force Office of Scientific Research Young Investigator Program Award, Invitee for 2016 National Academy of Engineering US Frontiers of Engineering Symposium, and 2011 Materials Research Society Graduate Students Gold Award.

他曾担任科学报告的编辑委员会成员和材料研究协会公告的客座编辑。亚博网站下载目前,他分别担任多功能材料和传感器的编辑委员会成员。亚博网站下载在国际会议上,他一直在与生物启发的材料,3D打印和机械超材料进行约35个研讨会。亚博网站下载他是美国机械工程师学会(ASME),材料研究学会(MRS),美国物理学会(APS)和工程科学学会(SES)的成员。亚博网站下载亚博老虎机网登录他曾担任ASME软件机械技术委员会主席,副主席,秘书和编辑。亚博网站下载

免责声明:此处表达的观点是受访者的观点,不一定代表本网站的所有者和运营商Azom.com Limited(T/A)Azonetwork的观点。此免责声明构成了Terms and Conditionsof use of this website.