由...赞助TOFWERK2022年6月21日Reviewed by Emily Magee

用于蚀刻过程表征和监测的主要技术是光谱和质谱。尽管由于其非侵入性而在生产环境中理想,但光学技术仅适用于特定情况,无法解决所有化学物质和材料。亚博网站下载

图片来源:Tofwerk

质谱, by contrast, is a powerful technique for the analysis of any process gas. Careful consideration of differences in pressure, reaction time scales and process flow is essential for integrating mass spectrometers. Previously, these constraints have been addressed by the use of quadrupole mass spectrometers (residual gas analyzers, RGAs). As the semiconductor industry incorporates ever-more materials in highly complex stacks for the design of the next-generation chips, however, a situation is created by the limited mass range and low mass resolution and sensitivity of RGAs in which they are simply no longer able to master the challenges of integration.

TOFWERK的工艺气体分析仪

The pgaTOF from TOFWERK is an electron ionization time-of-flight mass spectrometer and was developed specifically to overcome the limitations of RGAs. Simultaneous detection of all ionized species with isotopic resolution, greater than 105 dynamic range and a mass spectral acquisition rates up to 1000 Hz are provided by the pgaTOF. In order to guide process control action and to inform analytics and process intelligence, all process gas and etch products are monitored. Optimizing flow rates and ratios, monitoring substrate temperature, or detection of process excursion from optimal conditions or malfunctions are all included in immediate modifications of process conditions.

自发和血浆增强硅的蚀刻

Two well-studied, semiconductor-relevant chemistries were investigated in this proof-of-concept etch experiment with the pgaTOF – the first, spontaneous Si etching in XeF2和CF中Si的第二个血浆蚀刻4/o2化学。

通过约1米的波纹管,将PGATOF连接到过程反应器。PGATOF在自发蚀刻情况下直接连接到反应堆室。PGATOF在粗糙的泵级连接plasma etch system。该过程压力从大约3-400 mtorr(≈mbar)变化,样品温度范围从20 c到近200 c不等。

两种XEF的预期蚀刻反应2和CF4/o2conditions are shown below. It is important to note that non-volatile carbon compounds accumulate on the sample surface in a pure CF4等离子体,阻碍表面化学和产生较低的蚀刻速率和粗糙的表面。添加o2蚀刻气体导致这些非易失性化合物的反应和CO的形成2, greatly increasing the etch rate.

XEF中Si的自发蚀刻2

Si Etching with XeF2

(1)XEF2- > XEF + F-> XE + F2;Si + 2 F2- > SIF4

CF中的等离子蚀刻4和CF4/o2化学

下面显示了纯CF的Si蚀刻反应4CF的血浆(2)和(3)4/o2混合物

(2)SI + CF4- > SIF4+C

(3)SI + CF4+O2- > SIF4+ co2

实验结果

XEF的Si自发蚀刻2

SI样品(3厘米2)将插入原子层沉积(ALD)反应器中,该反应器拟合了XEF2具有可变脉冲能力的来源,并使用AR作为载气。

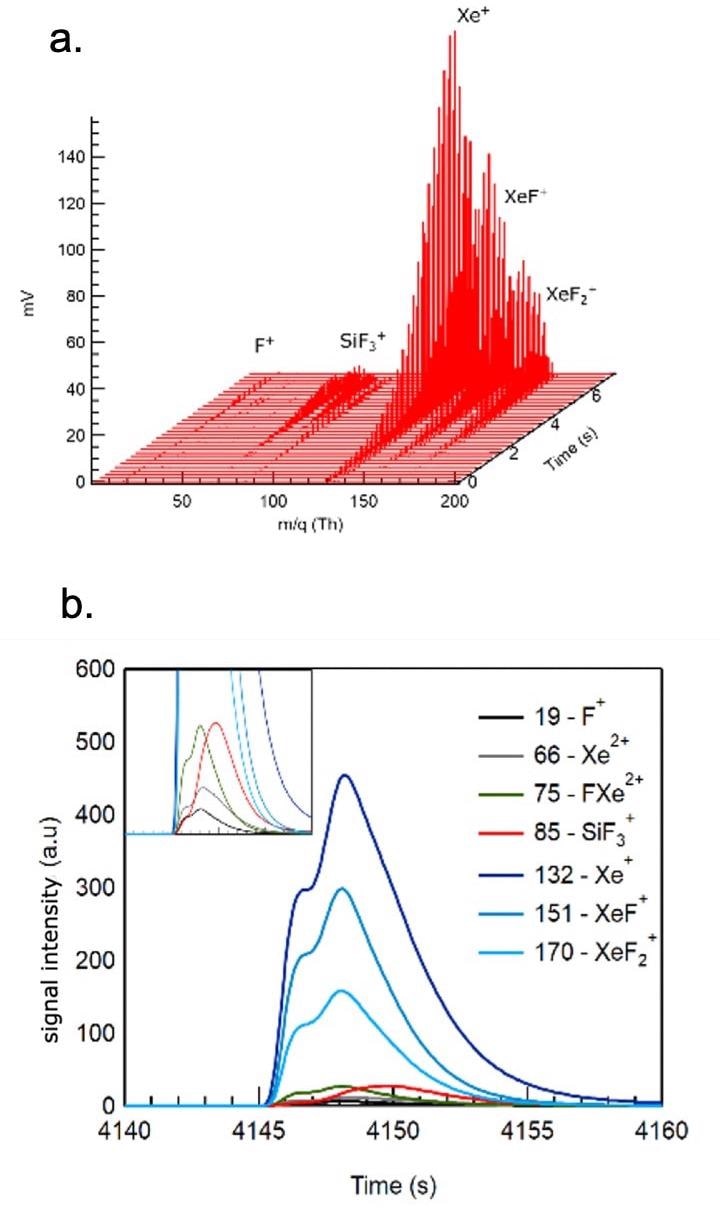

图1显示所有相关物种及其作为XEF的时间变化2pulse is introduced in the reactor.

在图2中,可以看到具有不同脉冲宽度的相同数据。

图2中描述的数据的详细分析表明,蚀刻气通量的实时优化和产生的副产品是可能的。这指出了在启动下一个过程周期之前清除副产品所需的最佳时间的能力,该过程与ALD情况相似,更重要的是在原子层蚀刻过程中。

此外,在过程开发和优化过程中允许检测从蚀刻率限制模式到加载限制条件的过渡。重要的是要注意,尽管样本量非常小,但仍针对所有物种测量大型信号计数。根据先前的结果和该蚀刻化学的已发表文献,预期这些过程条件的蚀刻速率明显小于每秒一秒钟。最后,随着PGATOF的飞行时间(无论是否提前已知)被记录并存储,以进行离线分析,理解和取证。

图1。用XEF自发蚀刻硅2。图1A(顶部)和1B(底部)显示了最丰富物种的时间演化,因为在脉冲模式下引入了蚀刻气体(在AR载体中100 ms和0.5 Mbar)。图片来源:Tofwerk

图2。用XEF自发蚀刻硅2showing the signal time variation of the most abundant species as the etch gas is introduced using pulses of different duration (0.5 mbar in an Ar carrier gas). Image Credit: TOFWERK

CF中Si的反应性离子蚀刻4/o2化学

Both a downstream microwave plasma etcher and a standard reactive ion etch chamber (RIE) were used to conduct these experiments. Only cm-sized Si substrates were utilized in both cases. Varying pressures and substrate temperatures. were used to perform these runs using both pure CF4和CF4/o2etch mixtures.

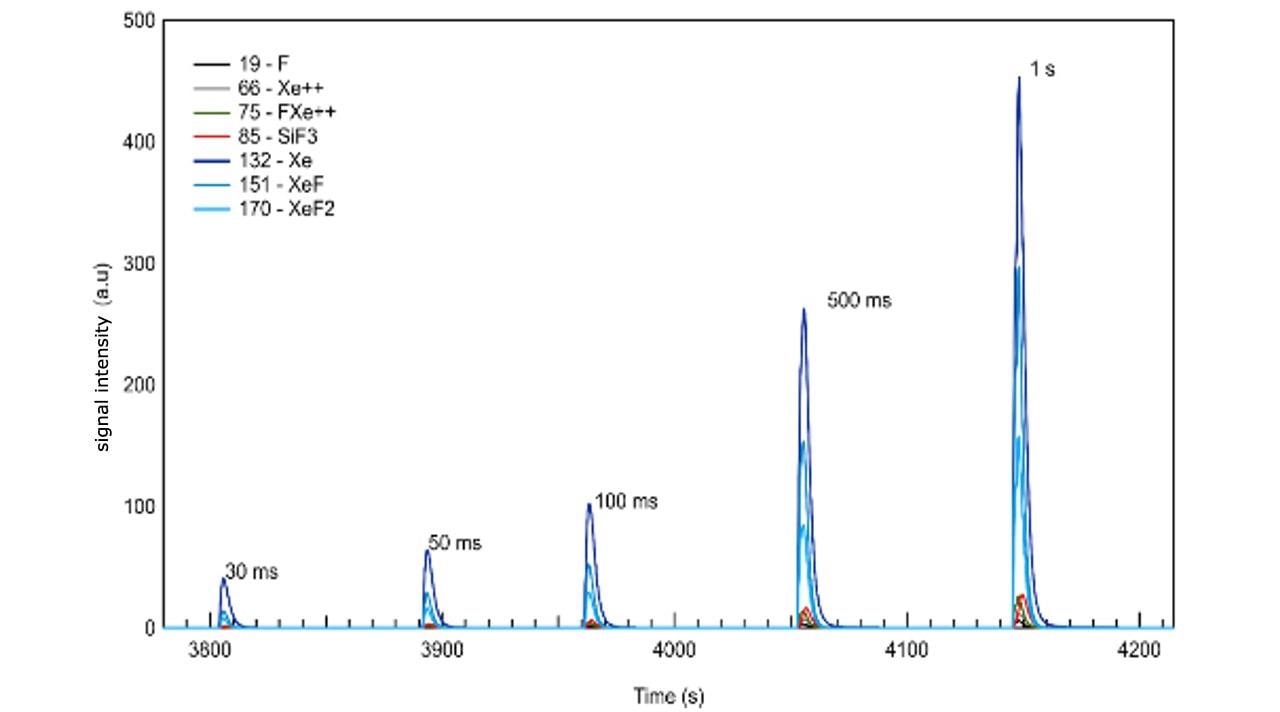

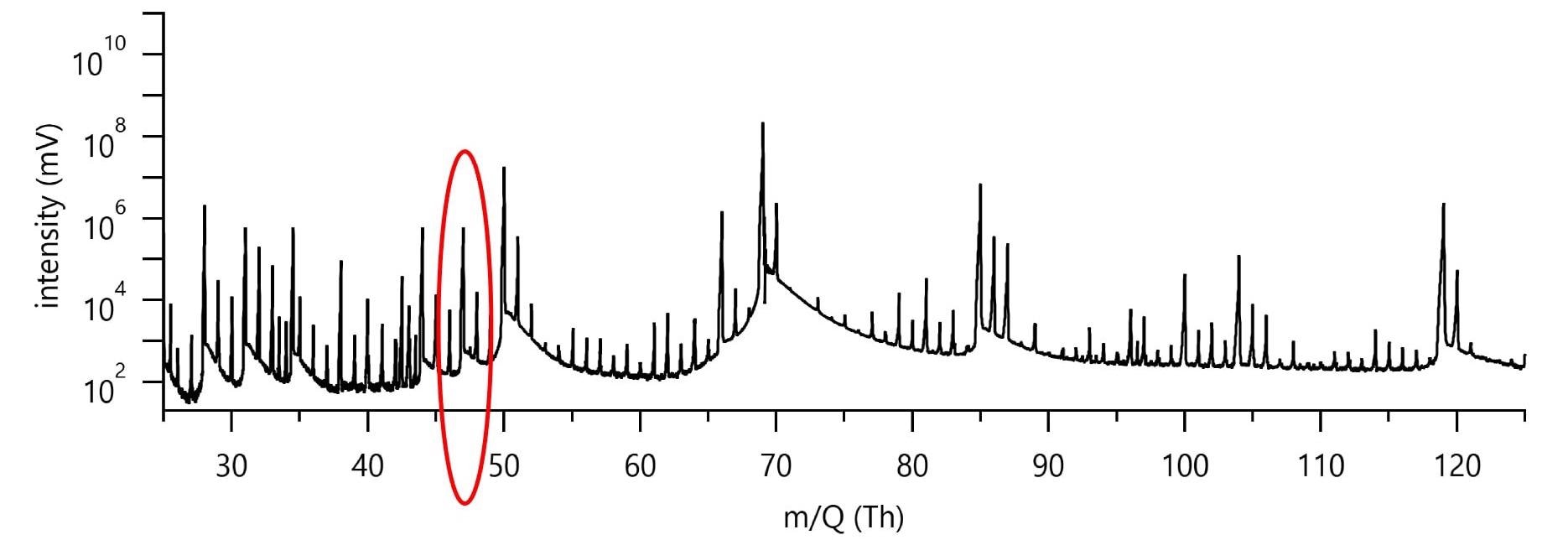

图3显示了纯CF的典型低质量数据4RIE etch run. The collected spectrum is dense with peaks, despite the simple etch chemistry and the most basic substrate.

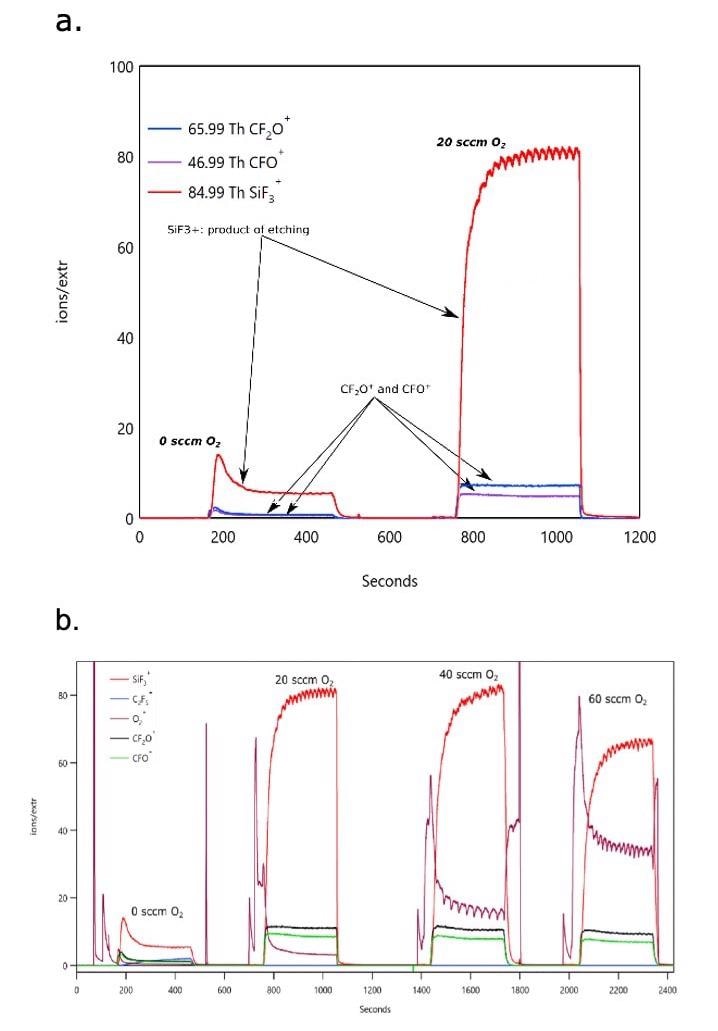

Figure 4 depicts the time dependence of relevant species in the mass spectrum as the plasma is turned on and off and the O2CF中的内容4血浆增加。

图3。Figure 3 shows typical spectrum during a Si etch run in a pure CF4等离子体(400 W,100 SCCM CF4)。图片来源:Tofwerk

图4。图4显示了在CF期间发生的血浆和蚀刻产品物种的时间演变4RIE process showing the effect of O2蚀刻速率增加。一种。(顶部)功率:400 W,100 SCCM CF4,O的可变流动2(0, 20 sccm), b. (bottom) Power: 400 W, 100 sccm CF4,O的可变流动2(0、20、40和60 SCCM)。图片来源:Tofwerk

蚀刻产物的丰度随着O而显着增加2内容,如预期的,但最终在约40 sccm(图3B)时达到其最大值,并且由于反应性物种稀释而开始减少该值。另一个感兴趣的是,由于O的差异很小2可以观察到蚀刻产品信号中的流速,可测量的振荡,随着它的移动超出最佳O2浓度(最大蚀刻速率),并进入反应性物种不足的状态。这种行为在厚层蚀刻中可能并不重要,但是在处理纳米结构设备时需要纠正。

pgaTOF Records All Compounds and Isotopic Distributions with High Mass Accuracy

甚至最简单的蚀刻化学(即CF中的Si)4等离子体产生复杂的质谱,其中观察到的峰的分配并不总是简单甚至可能,正如本原则证明的例子所证明的那样。

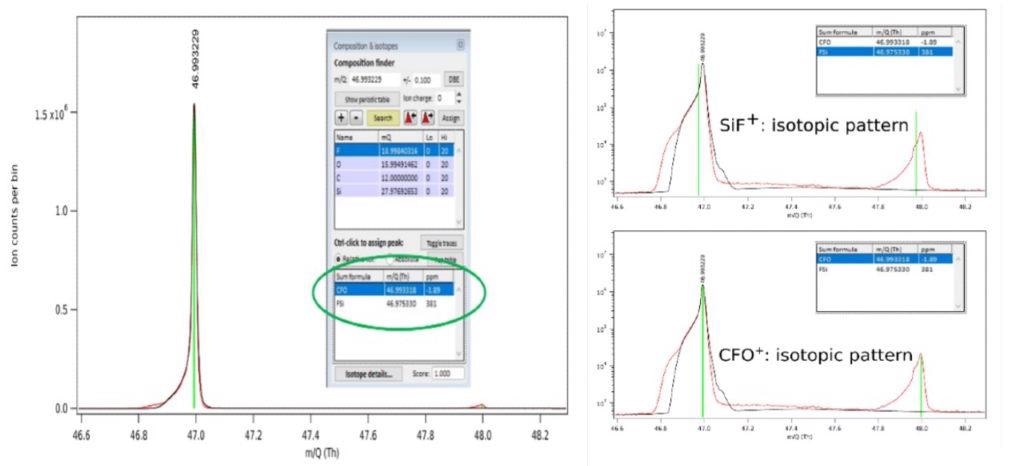

因此,重要的是要说明在红色圆圈内的图3中突出显示到特定的蚀刻气体或产品物种的第47次峰的挑战。唯一可能的物种应与纯CF的输入蚀刻气体和底物原子成分C,F和Si组合组合4血浆化学和底物发挥作用。

蚀刻产品SIF+,在46.974 th(383 ppm距测量峰的质量偏差)作为可能的分配,是通过使用的组成查找器函数提供的。pgaTOF’s software。但是,全质谱采集促进了小型但可测量的O的检测2将可能物种扩展到含氧化合物的信号。

构图查找器给我们CFO+在46.992 TH(0.2 ppm的质量峰值峰值)作为另一匹匹配。

为了更好地理解蚀刻化学,在这种情况下,将正确的规格分配给第47位的峰值至关重要 - 更重要的是,是确定过程完整性是否可以接受的关键;SIF+是预期的蚀刻产品,但CFO+意外的与杂质有关的规格。

Figure 5 condenses these results. The isotopic distribution is examined for the two possible species and their match to the experimental pattern in order to further improve the mass assignment. The isotopic distribution for both species is shown by Figure 5.b and it is clear that only CFO+展示了一个很好的视觉匹配。

Having established these two key observations, the peak at ~ 47 Th can therefore be unambiguously assigned to CFO+,这可能表明可能的泄漏(O2流量计或外部)或其他污染源。

图5。在纯CF中在SI蚀刻中获得的光谱中第47次峰的鉴定4血浆使用该仪器的高质量精度(左图)和测量的同位素分布峰具有对两个可能物种(右图)的预期位置。图片来源:Tofwerk

Conclusion

To conclude, connecting a mobile pgaTOF instrument to an etch reactor in a minimally invasive manner has been demonstrated to provide important process insights for even the simplest etch chemistry (CF4/o2) and most basic substrate (Si).

The real-time monitoring of all volatile compounds with high mass accuracy and sensitivity and sub-second detection of process changes was demonstrated. In unambiguous species assignment, the pgaTOF’s ability to measure masses with very high accuracy and resolution was shown to be critical. On-line reactor health assessment and off-line data analysis for process optimization and failure analysis was facilitated by intrinsic measurements of all species.

此信息已从Tofwerk提供的材料中采购,审查和改编。亚博网站下载

有关此消息来源的更多信息,请访问Tofwerk。