安大略省由可再生,清洁的能源风农提供动力,如果预见到重大组成部分故障,他们的预期寿命可能很长。

图片来源:SDT超声解决方案

Yet, wind turbines present unique challenges for condition monitoring technicians as they are complex assets consisting of both slow and high-speed components. With safety training and advanced technologies, these challenges can be overcome.

The height where data must be collected is one such challenge. Wind turbines in the United States have an average height of 280’ (85.3 m). This poses significant safety and accessibility concerns for condition monitoring technicians.

后勤噩梦失败或失败的组件需要更换或维护是另一个挑战,可靠性技术人员必须克服。

在这两种情况下,都需要使用训练有素的操作员进行多天的昂贵重型机械。这意味着最大程度地减少成本超支或减轻所有这些方法的最佳方法是提前几个月或几个月计划这些干预措施。

风力涡轮机组件的不同旋转速度是条件监测技术人员面临的第三个挑战。振动分析非常适合监视快速旋转的资产,例如主发电机上的驱动器端和非驱动端轴承。

涡轮机的缓慢旋转组件是振动降临的地方。发电机的轴承的转速要比风力涡轮机上的主轴承快得多。

Slow-speed bearings create insufficient vibration, making them ineffective as monitoring tools. Thus, condition monitoring technicians put their trust in ultrasound technology to monitor slow-rotating assets.

可访问性

The height at which condition monitoring technicians must perform their data collection is the most glaring accessibility challenge they face. Technicians must complete a mandatory eight-plus hour Working at Heights safety training course before even ascending a wind turbine.

每当在高度工作时工作时,员工安全的要素都需要考虑。对于在没有升降机的涡轮机上工作的技术人员,尤其如此。对于梯子上爬上50-100米的技术人员,尤其是在一天之内将其上升多次时,还有一个额外的疲劳元素。

此外,它消耗了技术人员的宝贵时间,必须整天反复上升和下降。随着时间的稀缺,陪伴成为一个明智的考虑。

将数据流向风电场维护总部的永久性监测解决方案是极高高度的理想选择。降低了风力涡轮机的频繁旅行的需求,该部门运营的可靠性和整体维护效率得到了提高。

Forewarning of Critical Component Failure

Maintenance crews must act swiftly to restore operation to the turbine when critical components inside the nacelle fail. It is an expensive and difficult challenge to replace and repair large components at extreme heights.

For performing this maintenance on wind turbines, skilled labor and heavy-duty cranes are necessary. The cost and headache of coordinating these maintenance efforts are reduced by finding faults and predicting impending failures far in advance.

The D-I-P-F curve is a common model outlining the typical life of an asset. Ultrasound technology owns the APEX of the D-I-P-F curve, as shown in the following diagram.

The largest window of opportunity for corrective repair is provided by ultrasound as it detects impending and potential failures earlier than vibration, infrared or any other condition monitoring technology.

图片来源:SDT超声解决方案

Inside the Nacelle

Reliability and maintenance technicians can perform their job better and more efficiently by choosing the right condition monitoring technology. A wind turbine’s critical components are depicted by looking inside the nacelle.

涡轮叶片通过主轴承连接到其余机构。根据风速,这款主涡轮轴每分钟旋转10-20个旋转。非驱动端,发电机驱动器端和涡轮机的变速箱的变化速度比慢速主轴快得多。

图片来源:SDT超声解决方案

Success Story

Matt Jeffrey,Mark Nanni和Robert Dent-所有SDT超声解决方案代表 - 最近安装了第一个警惕的在安大略省西南部的90米高风力涡轮机上的系统。

警惕是具有振动和超声分析功能的条件监测的永久解决方案。每个警惕的POD都可以连续管理八个数据源的输入(无需多重复杂)。

通过蜂窝,以太网或wifi,将数据流的条件监视数据流到其在车载趋势和分析应用程序中。关于其遥远和关键资产健康的信息的持续饮食被提供给可靠性团队。

任何技能水平的分析师都将能够轻松访问通常保留用于昂贵的高端振动软件的复杂分析工具。由于应用程序基于Web,因此也没有棘手的许可设置。用户只需要使用他们喜欢的浏览器登录即可开始分析。

The turbines’ critical components were already being permanently monitored using vibration analysis. Vigilant was deployed to use ultrasounds to monitor seven key data collection points.

涡轮机发电机的驱动端和非驱动端都放置了一个数据收集点,一个数据收集点在慢速主轴承上,而四个在变速箱上。

涡轮机的速度比主发电机上的轴承慢91倍,这意味着超声是监视慢速主轴承的最佳选择。

超声警告用户对安全,正常工作参数的变化,并揭示了即将发生的故障,因为它可以接受由摩擦和影响引起的低能事件的微音变化。

现在,所有关键数据收集点都从更完整的分析中受益,并通过振动和超声检查的智能数据安装了警惕。

The installation was completed very quickly by SDT personnel, and condition monitoring data was streaming from the Vigilant System 90 meters in the air to the wind farm’s maintenance office in just under two hours.

Analysis

图片来源:SDT超声解决方案

行星轴承 - 超声读数证实了影响的存在,如初始振动数据所预期的那样。

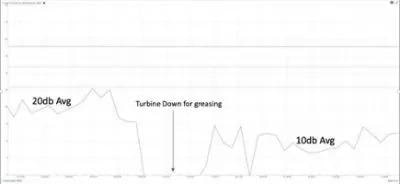

慢速主轴承 - 比预期的超声读数还要高。SDT的建议是润滑轴承。

图片来源:SDT超声解决方案

之后,超声分贝水平下降,表明撞击和摩擦的降低,这在下图中可见。

慢速主轴承,油脂之前和之后。图片来源:SDT超声解决方案

图片来源:SDT超声解决方案

图片来源:SDT超声解决方案

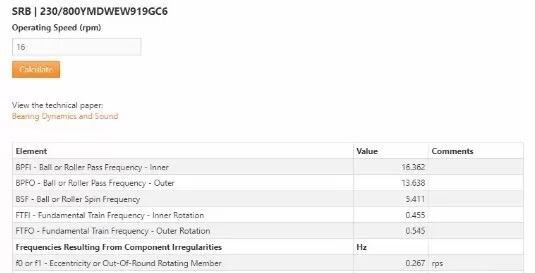

The main bearing had additional analysis conducted on it. It was discovered that there were repetitive impacts at a BPFO of approximately 13.5 times the running speed, which is consistent with an outer race defect.

SDT的建议是密切监视主轴承的状况。最终,由于缺陷,主要轴承将需要更换。

安装警惕的System benefitted the wind turbine maintenance by granting seven permanent ultrasound data collection points on the critical components of their wind turbine. They were able to confirm a suspected defect on the planetary bearing using their new data, which was originally detected using vibration analysis.

还发现了已经被振动传感器未发现的主要轴承上的新缺陷。技术人员注意到在主要轴承上施加了一些油脂后,摩擦水平显着下降。向前迈进,技术人员将继续密切监视主要轴承。

此信息已从SDT超声解决方案提供的材料中采购,审查和调整。亚博网站下载

For more information on this source, please visitSDT超声解决方案。