Chemical mechanical polishing (CMP) is a process of global planarization that leverages the synergetic effect of chemical reactions and mechanical abrasion to facilitate wafer polishing.

CMP has become one of the cornerstone techniques in contemporary integrated circuit (IC) manufacturing processes, ranging from position lithography and patterning steps to controlling topography and maintaining appropriate wafer surface characteristics.

这importance and use of these applications have increased due to ongoing demands for reduced device sizes, and enhanced performance has driven the need for increasingly stringent requirements around semiconductor manufacturing.

这refore, it is essential that new and evolving CMP technologies meet these requirements while accommodating new demands as they arise.

This article explores how Bruker’sTriboLab CMPrises to these challenges. This instrument offers reliable CMP quality control and optimization, as well as helping to optimize the evaluation of novel CMP technologies by both suppliers and end-users – both in series and in parallel.

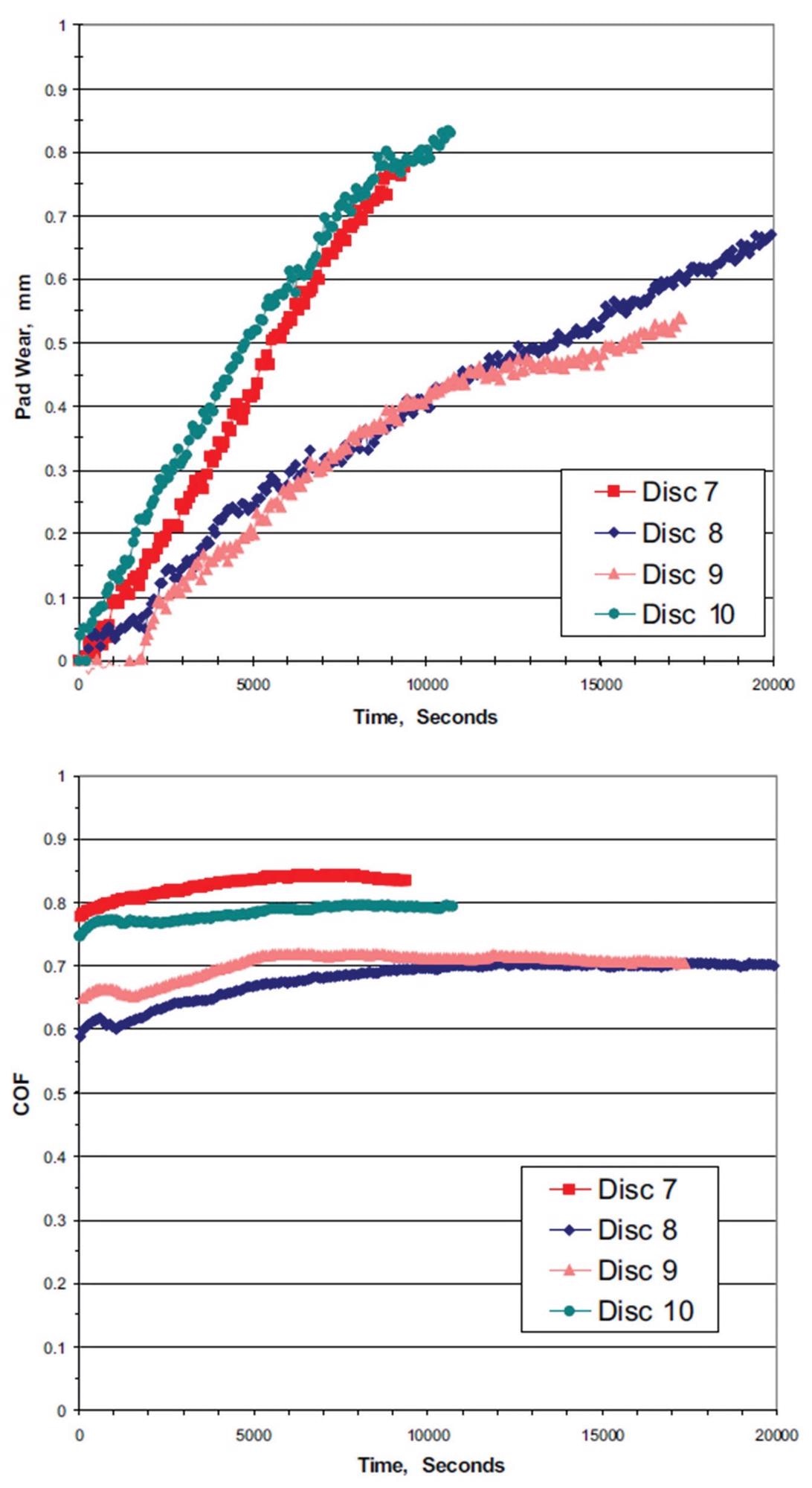

图1。顶部图显示了垫子磨损速率的毫米。调节光盘8和9显示较低的磨损。这bottom graph shows friction variation with time, and conditioning discs 8 and 9 also showed longer stabilization time (in terms of COF). Image Credit: Bruker Nano Surfaces

Quality Control of CMP Processes

这large number of different components involved in owning CMP equipment result in high maintenance costs. In 2013, the value of the CMP market exceeded 2.5 billion dollars, with the consumables market exceeding the value of the systems market.

这些高昂的拥有成本的大部分与制造过程的低效率有关,例如,波兰速度漂移和过量下压力(FZ)。

Bruker’s TriboLab CMP represents a reliable means of mitigating these issues thanks to its easy-to-use evaluation routines, including custom test creation capabilities and a series of pre-defined monitoring and quality control recipes.

CMP is employed alongside precise and accurate metrology measurements to manage product quality and consistency as part of CMP processes. Even the slightest variability in terms of the chemicals used or the process conditions can have a direct impact, prompting variations in processes and polish metrics.

这se variations can cause issues such as selectivity, corrosion, defects and inadequate polish rates. These problems can be directly addressed on a smaller scale through the use of the TriboLab CMP, allowing these to be negated before the onset of significant detrimental effects with full-scale CMP usage.

One ofTriboLab CMP的关键优势在于它的小占地面积。这种紧凑的台式CMP系统经过设计和开发,可提供机械测试和表征,复制全尺寸的抛光过程条件和典型的消耗品磨损。

这instrument’s rotational motion is provided by pressurizing mechanisms on the wafer carrier.

整个实验中,集成的传感器监测并测量垂直力(FZ),声学排放和摩擦系数(COF)。这些传感器可以用作终点检测系统的一部分,从而使该系统可以在一系列特定的测试条件下工作。

When conducting polishing experiments on the TriboLab CMP, it is possible to cut round or square coupons from full-size wafers to fit inside the benchtop wafer holders. This feature affords users a significant reduction in wastage and costs, helping to ensure that R&D is as cost-effective and efficient as possible.

Pad conditioning impacts pad-wafer interactions, affecting the removal rate’s reproducibility.

去除速率漂移和“釉面”垫也可能对重现性产生负面影响,这意味着要调节垫子的表面原位(在抛光期间)或以前(在抛光之间)。

Conditioning the pad helps regenerate its surface while producing new pad asperities and removing any glazed areas.

Pad conditioners are tools specifically designed and tailored for each application, ensuring that the required roughness and porosity are consistently maintained throughout a pad’s lifetime.

Slurry transport and distribution will therefore be reliably maintained on the pad, with removal rate, polishing quality and planarity remaining steady, controlled and sustained throughout the pad’s lifetime.

正确维护垫子可以帮助降低CMP设备所有权的总成本。app亚博体育随着Tribolab CMP适应全尺寸型号的相同的PAD条件,用户能够更有效地监视这些问题。

这TriboLab CMP can be used to condition pads both in-situ and ex-situ, as well as for monitoring and measuring changes in COF, height, normal load and temperature over time. The faster that the COF stabilizes during conditioning, the more effective the conditioner is, and the longer the pad’s lifetime will be.

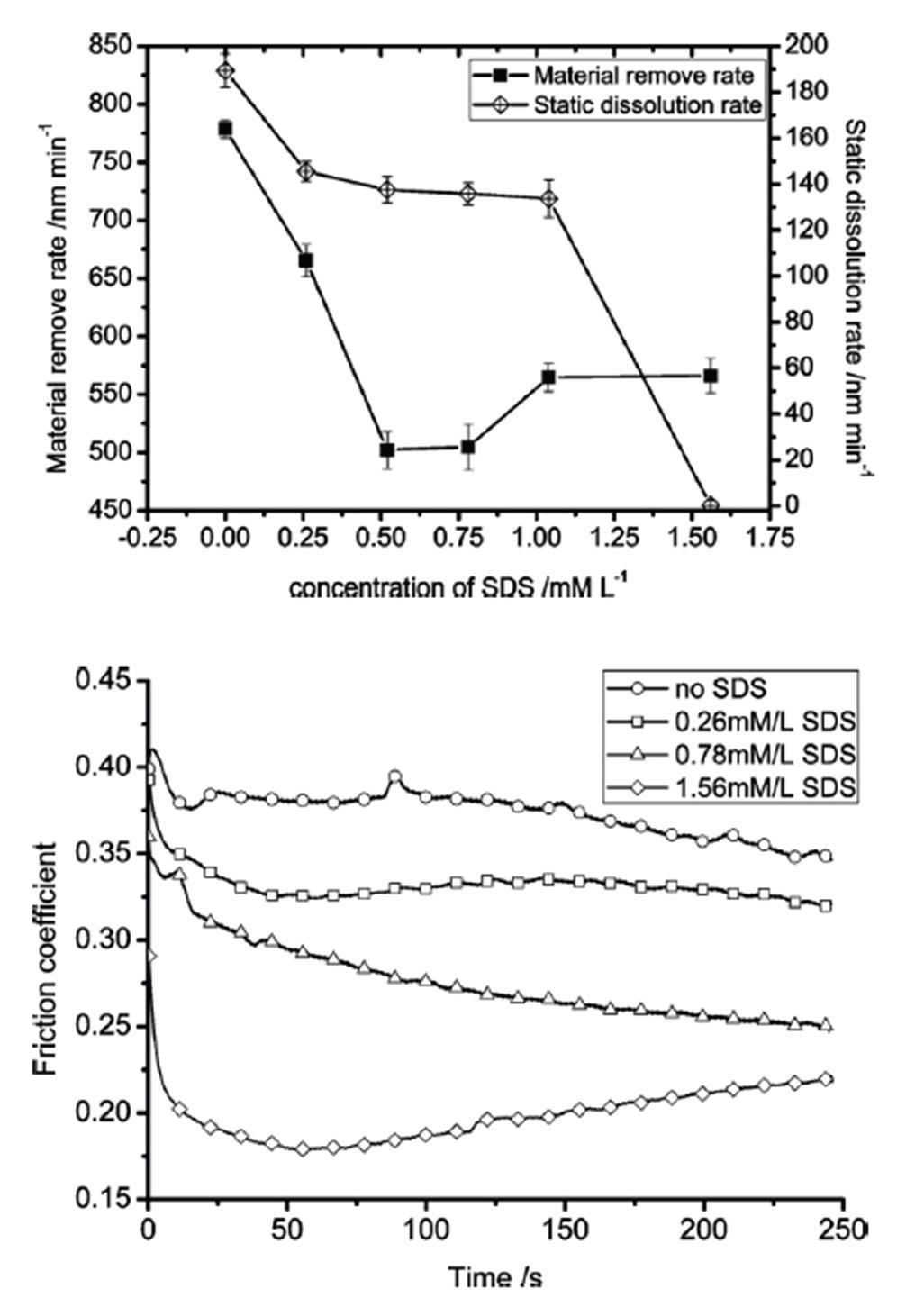

Figure 2 provides a practical example of CMP experiments conducted using a TriboLab CMP (taken from Yan Pan et al. 2010 J. Electrochem. Soc. 157 H1082).

图2。十二烷基硫酸钠(SDS)浓度对静态溶解速率和去除速率的影响;抛光铜(顶部)。与不同SDS浓度的时间变化的COF变化;抛光铜(底部)。图片来源:Bruker Nano表面

这些实验研究了浆料对抛光的影响,并探索并开发了一种物理模型,以实现十二烷基硫酸钠(SDS)对抛光的影响。

这study saw SDS surfactants added to the slurry at various concentrations. It also included hydrogen peroxide, glycine and silica particles.

如果要适合铜CMP,则需要满足两个要求:任何机械磨碎的氧化铜颗粒都必须溶于浆液中,并从抛光界面中取出。yabo214

相反,遇到垫的表面氧化和抛光速率应高于下层铜的去除速率。

下图显示,可以在没有表面活性剂的情况下实现高材料去除率,但是抛光表面上有许多划痕和凹坑。这些发现对应于最高的COF,这可能是由于机械磨损而导致的。

It was also noted that an increase in surfactant concentration led to a series of behaviors; for example, lower removal rates, followed by a slight increase in removal rate.

COF continued to decrease as more SDS was added, demonstrating a correlation between changes in the surface’s chemical properties. This resulted in surface variation and impacted the surface’s zeta potential, wettability, and ionic strength.

Increasing the SDS concentration to a total of 0.75 mM/l was also found to limit the number of scratches and corrosion throughout polishing – this ultimately resulted in a more effective CMP process.

该表征测试以及类似的测试是最小化成本的关键。

CMP Process Optimization

与CMP系统相关的高昂所有权意味着该产品必须始终表现出最佳功能。Tribolab CMP可以通过用户友好的测试编程和监视原位和前景来支持CMP流程优化。

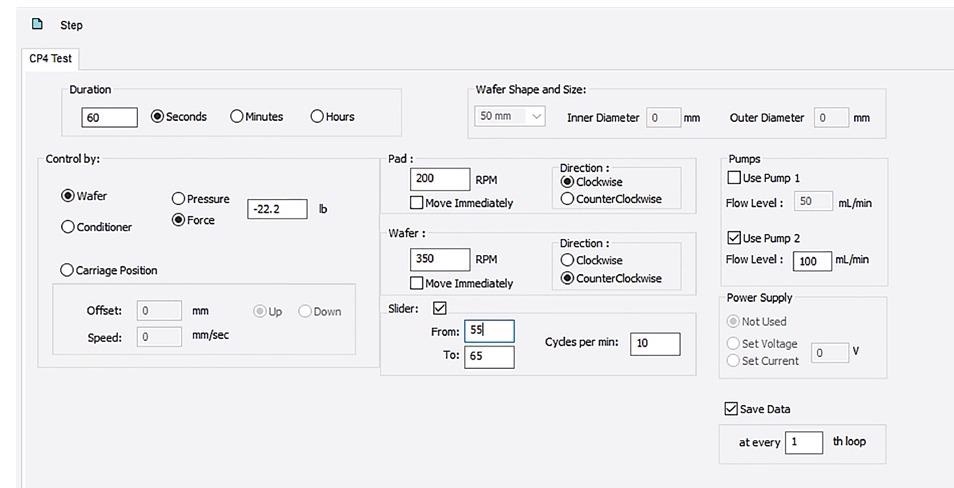

Available software has made writing recipes straightforward, with each recipe able to include one or more sequences – each comprised of one or more steps.

这些序列可以单独或串联运行,所有数据通道都保存到数据文件中;例如,正常力,声发射信号,摩擦力(在抛光头和调节盘上),垫温度和高度。

每个参数都可以在每个步骤内部独立更改(图3),包括对护发剂或晶圆的负载控制,以及运输位置控制。

水和浆液饲料是可编程的,可以自动化,而泵可以打开或关闭,也可以设置为以特定的流速进行操作。最后,速度,运动方向和横向周期都可以改变。

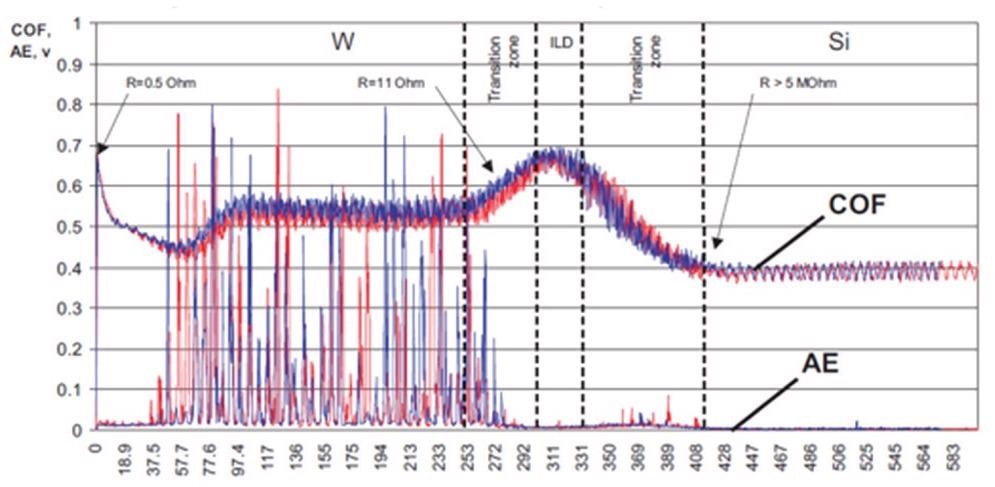

Monitoring the CMP progress in Bruker’s TriboLab CMP involves both in-situ monitoring and end point detection.

图3。Demonstration of TriboLab CMP Software. Image Credit: Bruker Nano Surfaces

In-Situ Monitoring and End Point Detection

这industry currently utilizes an array of end point detection approaches, including electrical, thermal, acoustic, vibrational, frictional and optical methods.

Bruker’s TriboLab CMP has been designed to accommodate this trend, with a wide variety of end-point detections available to evaluate a number of polishing process endpoints.

声发射(AE)已集成到晶圆袋中,以促进抛光过程中产生的COF频率频谱的检测。AE也可以用于检测微捕捉,层污染,弹性塑料和子层变形。

Pad temperature is also measured as part of endpoint detection testing. It is possible to analyze changes in the COF over time as part of endpoint detection, thanks to the TriboLab CMP’s ability to monitor pad wear by monitoring height.

图4显示了台式CMP演示的数据。该数据表明,在寻找抛光终点时,平行AE和COF测量如何相互补充。

图4。该图将COF和AE作为花费的抛光产品的产物。图片来源:Bruker Nano表面

Conclusion

这TriboLab CMPis able to address a diverse array of new and historical challenges in CMP use cases. The central problem addressed with Bruker’s TriboLab CMP is the significant amount of resources wasted through the use of inefficient CMP development processes.

Tribolab CMP通过有效且具有成本效益的测试,质量控制和过程优化来赋予CMP系统。

这些测试适用于大型设备和消耗品,可以通过广泛的摩擦学测量和用户友好的软件来完成,这些软件都包含app亚博体育在紧凑的足迹中。

As demands for ever smaller devices with ever-increasing performance requirements continue, it is expected to become even more vital that CMP processes are efficient and effective.

Bruker’s TriboLab CMP ensures this effectiveness and efficiency in a single benchtop tool and is ideal for end-users and suppliers, in series or parallel.

Acknowledgments

Produced from materials originally authored by Kora Farokhzadeh, Ph.D. from Bruker Nano Surfaces and Metrology.

This information has been sourced, reviewed and adapted from materials provided by Bruker Nano Surfaces.

For more information on this source, please visit布鲁克纳米表面。