The presence of flavors and fragrances is often subtle yet commonplace in our everyday lives. Like any other producers, the companies that manufacture flavors and scents are faced with numerous challenges to stay profitable while ensuring consistency and quality remain top priorities.

在设计制造设施以开发和将多种产品与常用的设备和工艺容器相结合的情况下,尤其如此。app亚博体育将原材料引入处理船舶,这些容器可亚博网站下载能会导致以前生产批次的残留物,可能会导致:

- 最终产品特征的变化

- Jeopardizing product safety

Batches that have been compromised will be rejected or recalled, which in turn negatively impacts productivity and leads to profit loss. Therefore, it is crucial that the cleaning of the equipment between production batches is carefully undertaken to avoid cross-contamination, which could affect product safety and quality.

Consequently, it is absolutely crucial to validate equipment cleanliness. Some manufacturers monitor the pH or conductivity of the rinse water throughout the final stages of the equipment’s在现场(CIP)周期。

While this method may help reveal the presence of inorganic impurities, some contaminants will remain undetected. It is also typical practice for these manufacturers to use test methods that are subjective and approximate in nature, including visual inspections or surface swabs.

挑战

A manufacturer of tobacco flavors in Asia conducted a validation of its cleaning process by manually swabbing wetted surfaces of its process vessels to run tests for traces of adenosine triphosphate (ATP).

ATP是所有活细胞中存在的化合物,该测试经常用于检测微生物污染。但是,也可以在不可行的细胞中发现ATP,从而显示出结果的可靠性和可重复性不一致。

测得的ATP值与设备中存在的残留物的实际量不符。app亚博体育该设施中产生的风味化合物不支持微生物的生长,因此,负ATP结果不一定与缺乏产品残留有关。

此外,当擦拭设备的润湿表面时,存在重新引入外部污染物的风险。app亚博体育

为了解决ATP测试方法的缺陷,制造商依赖于操作员检查,并使用其嗅觉寻找产品残留物。

Unfortunately, olfactory sensitivity is subjective, and the inspection outcome was not quantifiable. This makes it difficult for the manufacturer to exhibit control over the quality of the process, especially during customer audits.

解决方案

寻找用于清洁验证的监视解决方案,该制造商决定调查TOC分析。监测TOC可以促进快速,准确地检测风味和香料残留物,因为这些产品是有机成分或具有有机成分。

TOC分析还捕获了可能在CIP周期完成后可能留下的少量烃类清洁剂,从而提供了清洁效率的总体快照。

制造商从Suez选择了Sievers* M9 Portable TOC分析仪,由姊妹设施推荐其评估品质。通过依靠紫外线和强大的氧化试剂,Sievers M9 TOC分析仪可以轻松完成完整的样品氧化。

It also includes a unique membrane conductometric detection technology, which allows the analyzer to deliver consistent, accurate and precise readings in just two minutes, even when TOC levels are as low as sub-ppb concentrations.

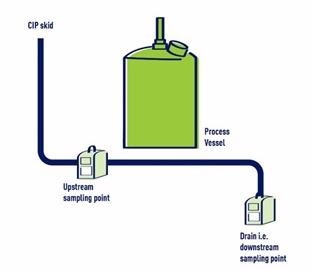

The SUEZ team assisted in the development of a TOC monitoring program for this facility by recommending that samples be collected at the equipment drain point during the final rinse step of the CIP cycle. A comparison of these measurements with the initial TOC baseline of the incoming rinse water provides a solid understanding of cleanliness.

如果在退出冲洗阶段时显示出TOC值升高,则表明设备中存在残留产物或清洁剂。app亚博体育在这一点上,制造商可以扩展最终的冲洗步骤或重复CIP循环,直到达到适当的设备清洁度。app亚博体育

制造商的TOC监控计划的描述。图片来源:苏伊士水技术和解决方案

*苏伊士商标;可以在一个或多个国家注册。

结果

The manufacturer determined that incoming rinse water values stabilized around one ppm following a period of data collection using the Sievers M9 TOC Analyzer. If the CIP cycle demonstrated its effectiveness, this value would be consistent post-rinse.

如果任何产品残留物保留在设备中,TOC值将在4到5 ppm之间增加,从而显示出明显的app亚博体育污染证据。对结果的评论表明,TOC分析提供了:

- 与常规ATP测试相比,准确检测产品残留物

- A more dependable test method than olfactory inspections

- Quantifiable data

- 改进的过程理解

除了确保对产品质量的控制的额外保证外,制造商还对使用TOC数据来增强现有CIP程序的可能性也很感兴趣,因为这可能会产生节省成本的机会。

例如,用于生产易于清洁产品的app亚博体育设备可能只需要较短的冲洗时间或更少的清洁化学品。

A promising feature of the Sievers M9 Portable TOC Analyzer is its adaptability for use at-line or on-line monitoring. This feature gives the manufacturer flexibility when acquiring data in real-time - data that can facilitate key equipment release decisions.

该客户也对安装的简单性感到惊讶SIEVERS M9 TOC分析仪,特别是因为它不需要外部压缩空气来发挥作用。

他们发现该乐器易于维护,并且每年只需进行一次校准。该设施已引入TOC分析,作为其质量控制过程的一部分。

总而言之,与Sievers M9的TOC分析为该口味制造商提供了一种可靠,全面和可量化的方法,用于验证设备清洁度以保护其产品的质量。app亚博体育

TOC数据不仅用于确认在容器表面上清除痕量产品残留物,而且还用于验证充分去除清洁剂并改善CIP循环。

This information has been sourced, reviewed and adapted from materials provided by SUEZ Water Technologies & Solutions.

For more information on this source, please visit苏伊士水技术和解决方案。