微胶质继续进行证明他们的advantages for展示市场是一种不断增长的技术,该技术不断地融入新产品系列中。

These minuscule light-emitting diodes (LEDs) are individual elements that typically measure below 100 µm—about 1/10th the width of a human hair—and some are even less than 3 µm. Their benefits over other display types include faster response times, higher brightness, and lower power consumption. MicroLEDs offer the potential for wider color gamut, higher contrast ratio, and deeper blacks than LCD (liquid crystal display) and OLED (organic light emitting diode) displays.

微胶片平等的OLED技术为了观看角度的性能和响应时间,但在消耗较少的功率的同时,亮度和坚固度就超过了OLED。这些好处正在推动对技术的大量投资,并推动市场预测估计到2025年运送的最高3.3亿辆。1

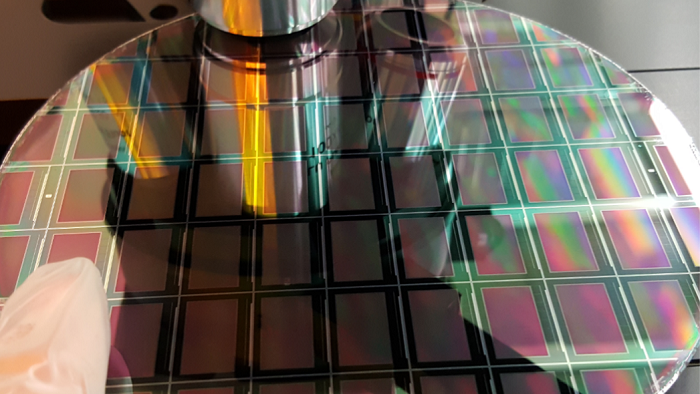

图片来源:辐射视觉系统

As the demand increases for better and higher resolutions, microLEDs are positioned to be the next technology to breakthrough in various areas of the display industry. Their tiny LED size and reduced pixel pitch produce vividly clear images. Their appeal is especially desirable for manufacturers of devices such as smartwatches, augmented reality (AR), and head-up displays (HUD): displays where high luminance and resolution are critical for visual performance in small spaces, under variable ambient lighting conditions, or at close proximity to the eye.

发射显示的质量挑战:不均匀

为了充分发挥微胶片显示技术的潜力,必须克服生产中的一些挑战。确保OLED和Microled等发射显示的质量和统一性是一项艰巨的任务,因为单个二极管是其自己的发射极,它是独立驱动的。因此,由数百万微胶片组成的显示可以显示出亮度和颜色的巨大变化。

来自plessy半导体的整体微胶片显示器的背板(图像来源)。

This variability can lead to an inconsistent appearance (non-uniform color or brightness throughout the display) that is noticeable to the viewer. Thus, a display with uniformity issues cannot be sold. Whether measuring microLEDs at the singular wafer level after deposition onto a substrate or once positioned onto the display backplane of a consumer device, microLED manufacturers need an inspection approach they can depend on to measure and quantify microLED light and color output with great accuracy to permit correction and consequently increase yields.

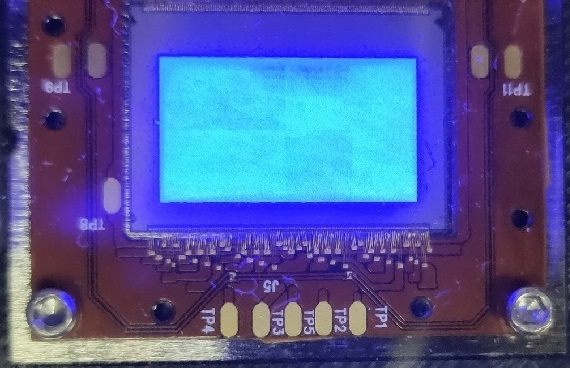

可变亮度在此0.7“微玻璃面板(Full HD,1920x1080)中产生不均匀的外观,LED尺寸为2µm,像素螺距为8µm。(图像©Jasper Display Corp.)。

A display metrology system must be able to precisely identify and measure the luminance (Lv) and chromaticity (CIE x,y or u’,v’) of individual pixels and subpixels; that is, each diode, to ensure microLED device quality. Radiant’s high-resolution, low-noise舞会®Imaging Photometers and Colorimeters证明precision measuring of microLEDs, proven to acquire accurate and repeatable luminance and chromaticity values for every single microLED beyond the capacities of competitive measurement systems.

首先,每个像素的隔离都可以通过Radiant的TrueTest™自动化视觉检查软件中的图像分析工具进行量化,从而可以量化它们。随后,然后计算单个校正系数并将其应用于每个微玻璃,以确保相等的输出和均匀的显示外观。Radiant的基于图像的测量系统提供了像素级的精度,精确制造商需要正确检查和纠正微胶片显示器,以达到产品质量的必要标准,从而使生产效率能够满足市场需求。

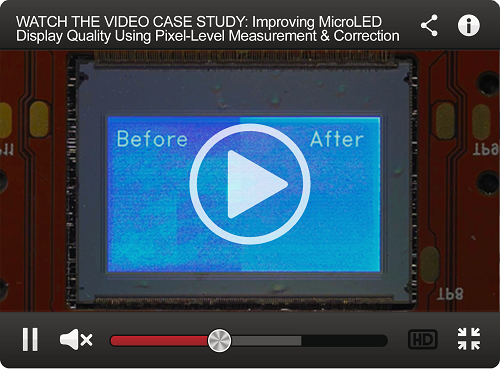

现在,先前图像中显示的相同的微胶片显示器在测量和校正后使用Prometric具有均匀的亮度®Y29(29百万像素成像光度计)使用Truetest™软件的Demura算法使用显微镜镜头。(图像©Jasper Display Corp.)。

案例研究:贾斯珀展示

Jasper Display Corporation and other display innovators selected Radiant Vision Systems to enhance the visual quality of developing technologies like microLEDs. Utilizing Jasper Display’s微玻璃入门套件, Radiant’s advanced pixel measurement and uniformity correction (demura) solution provides manufacturers with an assist to accomplish their goals for effective microLED display development while securing perfect visual display quality.

带有显微镜透镜附着的Prometric Y29成像光度计已有效地测量和纠正微胶片显示器的亮度均匀性。图片来源:辐射视觉系统

观看视频案例研究与Jasper Display Corporation一起了解更多信息:

- 像素级测量和均匀性校正(Demura)对显示质量和生产效率的影响

- 诸如微胶片,微小和OLED等发射显示器中的不均匀性挑战

- How Radiant’s high-resolution ProMetric®成像系统和软件适用于微型微型播放的高速和准确的Demura,例如使用Jasper Display的技术制造的微型播放

图片来源:辐射视觉系统

参考

- 微胶片显示, report from Yole Développement, February, 2017. Retrieved from: http://www.yole.fr/MicroLEDDisplays_Market.aspx

Acknowledgments

由最初由Anne Corni亚博网站下载ng从Radiant Vision Systems撰写的材料。

此信息已从Radiant Vision Systems提供的材料中采购,审查和调整。亚博网站下载

For more information on this source, please visit辐射视觉系统。