A large concrete and construction company based in the Midwest of the United States had an issue with limited visibility of inventory control at their primary dispatch.

Image Credit: BinMaster

Constant silo climbing and dropping of tape measures led to a time-consuming and inaccurate process that had to be managed by the具体的供应商的工人,甚至在考虑这种方法带来的潜在安全危害之前。

需要集中监控

调度需要对十种本地植物和许多其他偏远工厂位置进行实时库存监督,以满足对粉煤灰和水泥粉的需求。如果所有位置有效地运行,改善水泥植物本身和批处理植物之间的物流至关重要。

The two full-time members of staff were overwhelmed, as it was their job to schedule and route all the trucks for the ten local plants located around the metropolitan area, as well as the trucks for the remote plants. BinMaster was ready for this challenge, and was able to work with the company to help it manage this complex logistical issue.

Image Credit: BinMaster

后勤挑战

每个批处理植物位置均管理了五到八个I型水泥粉,粉煤灰和IPF的孤岛,并且每个原材料都必须填充这些原材料。亚博网站下载一系列十种植物的粉煤灰主要由附近的发电厂提供,而I型水泥粉和IPF则是从单个水泥厂订购的。

The company’s trucks held approximately 32 tons of material per load. It was imperative that all of the material could fit into the silos when the trucks made a delivery, so staff had to ensure that there was sufficient space for the truck’s entire contents to empty into the silo.

Effective coordination of all of these variables was critical in order to prevent the company from losing both money and time.

Non-Contact Radar Relief

为了允许连续测量筒仓水平而不需要攀爬,Binmaster的Nathan Grube建议使用80 GHz非接触式雷达级传感器。工厂的维护人员能够将孤岛本身预先前,因此可以适应传感器的安装。

Binmastertechnical services could complete the commissioned work in a day or two per location, and over time,NCR-80 sensors成功安装在58个孤岛中,以及应用作冗余高级警报的旋转水平指标。

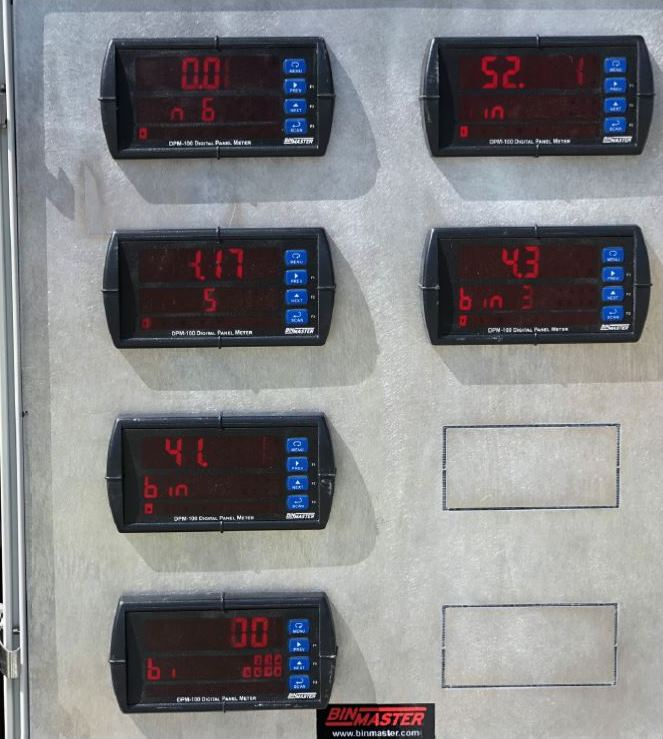

Because the silos rapidly fill up in as little as four to five hours, DPM-100 digital panel meters were installed to report headspace levels. A BinCloud®网关允许将数据从传感器传达到面板表,而无需广泛的接线。

定制橱柜现在容纳了几个数字面板仪表,可以从中央位置访问筒仓数据。

现在,两个主要的卡车司机,或者确实在工厂工作的任何人都可以随时检查筒仓顶空。这使驾驶员可以自信地装载筒仓和空卡车,并确保材料合适。

Image Credit: BinMaster

Image Credit: BinMaster

软件将解决方案全圈

Real-time views of inventory levels at each individual batch plant were vital to keep pace with the rapidly changing silo levels. The corporate headquarters dispatch location was provided with access to a BinView®remote monitoring website, and this was also made available at each of the plants.

随着所有员工查看相同的数据,库存差异已成为过去。驾驶员,调度员和工厂经理现在可以在减少库存外和交付紧急情况的同时设定优先级 - 浪费时间,对利润和时间表产生不利影响。

Thebinview®softwarelets dispatchers monitor and order materials for several locations, while plant managers now have easy access to inventory information for their location as required. Users can view and sort bins by material, as well as being able to set automated alerts, examine trends, and generate detailed usage reports.

Image Credit: BinMaster

Image Credit: BinMaster

Rock Solid Results

The concrete company had said that they,“couldn’t afford to run out or risk messy overfills.”Thanks to BinMaster’s products, staff no longer have to manage the risk of climbing outdoors, in weather that can be very hot, cold or windy in a location like the Midwest. Staff at the cement supplier also said that they “really like the visualization of what’s going on.”

Image Credit: BinMaster

他们可以查看所有位置的数据,只有一个位置,或者只是需要填充的垃圾箱。而且由于植物如此活跃,因此每10分钟就会获得一次更新。年轻人认识到技术的价值,而植物面临着尝试与更少的人进行更多工作。

Nathan Grube, Binmaster

Acknowledgments

由Binmaster最初由N亚博网站下载athan Grube撰写的材料生产。

This information has been sourced, reviewed and adapted from materials provided by BinMaster.

For more information on this source, please visitBinmaster。