ACP复合材料found the need to provide a high-quality sandwich panel that appeals to their customers but does not require the strict aerospace processing standards.

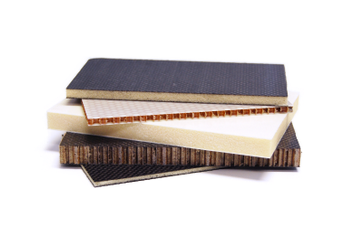

Image Credit: General Plastics

更具体地说,APC希望提供一个可靠,通用性且具有成本效益的三明治面板,比使用通用核心材料Nomex Honeycomb的其他面板更具成本效益。它也必须有各种厚度和密度。ACP决定使用聚氨酯泡沫核心材料。

泡沫还需要足够稳定才能在250中生存of处理温度和应用,而不会以任何方式缩小,变形或变化。

我们已经尝试并测试了您可以想象的所有泡沫,我已经着火了,有些泡沫在处理过程中甚至崩溃了。

ACP复合材料首席执行官Justin Sparr

“其他可以完成这项工作的泡沫价格过高或领先太长。因此,这将限制我们执行不断满足客户的交付和生产计划的承诺。”

Key Requirements

- Cost-effective

- 稳定,高性能的泡沫核心材料

- Can be cut into various thicknesses

- Withstands 250°F (121°C) processing temperature without deforming

- Readily available without long lead times or a hefty minimum quantity requirement

- Highly machinable

- Available in a variety of densities

Solution and Application

APC Composites found thatLAST-A-FOAM®FR-3700 series polyurethanefrom General Plastics was the most reliable and consistent material that met all the requirements.

通用塑料的泡沫非常适合我们的需求。It is a high-performing, economically viable solution that stays stable under our high-temperature processing applications. The company also offers comprehensive technical data sheets on all their foam materials, which makes it easier for customers to verify it fits their application requirements.

ACP复合材料首席执行官Justin Sparr

FR-3700是一个封闭的燃烧器,刚性聚氨酯泡沫that is available in a broad range of densities. It is less friable and tougher than other rigid foam materials and is aerospace-grade, BMS 8-133-qualified.

This means crisper edges can be cut, so it is well-suited to machining complex shapes for composite cores. Due to its cellular structure and cross-linked resin, LAST-A-FOAM®FR-3700 has a high strength-to-weight ratio. It has great resistance to water absorption and will not split, crack, or swell when exposed to water. This series is non-abrasive and can be machined with standard high-speed steel (HSS) cutting tools.

Military Solar Array

Foam from General Plastics is used in a number of ACP’s customer applications. For example, the foam is used as a core material for portable, field-deployed military solar arrays.

When using electronics in the field, soldiers require a lightweight solar array that produces bulk energy to charge batteries and other electronics anywhere they are. ACP found that foam from General Plastics was ideal for this application because it fit the mechanical and budget needs of the customer.

Medical Positioning Table

泡沫面板还用于将患者定位在medical industry。一般塑料的泡沫芯使ACP可以在面板内安装碳纤维插入物。这提供了将螺栓螺栓插入其中或通过它钻一个孔的选项。

Usually, this type of carbon fiber table uses a polyacrylamide foam core. However, that material is much more expensive than polyurethane foam and has a much longer lead time.

使用一般塑料的泡沫,桌子的面板以相同的成像清晰度和尺寸稳定性和成像清晰度与聚丙烯酰胺泡沫相同,但价格较低。客户对泡沫的低密度和易于加工感到满意,而ACP现在有了该产品的常规订单。

Overall, I always know what to expect with General Plastics.它们很容易使用,我知道我总是会收到公司所在的高质量产品。

ACP复合材料首席执行官Justin Sparr

3700福利

- Flame retardant

- Stable and inert

- 对大多数化学物质和溶剂的抗性

- 交联树脂的高强度重量比

- Will not support fungal growth

- 表现良好

- Easily shaped with common woodworking tools

This information has been sourced, reviewed and adapted from materials provided by General Plastics Manufacturing.

For more information on this source, please visit一般塑料制造。