可以使用各种仪器和方法进行横截面的样品制备,并且根据自动化水平,该过程需要进行不同的设备设置。app亚博体育为了制备IC设备的简单SEM横截面,在既定的实践中基本上可以使用两种方法:封装的横截面和未封装的横截面。

封装横截面

封装的横截面方法是通过将横截面样品安装到环氧树脂或丙烯酸模具化合物中,通常的直径约为1英寸,并围绕所选设备,以确保样品更容易处理。

然后将模具接地并抛光,直到横截面完成。通常,该过程需要120至1200粒度的碳化物碳化物磨料纸,并最终以最终的抛光剂使用0.05μm的胶体硅胶进行了抛光布。

未包裹的横截面

未封装的横截面直接在所需的IC设备上执行。将样品切割为适当的比例(通常约为3 x 5mm),并固定在各种持有人上。随后使用30μm -0.5μm的钻石胶片膜来抛光样品,并最终以最终的抛光剂使用0.05μm胶体硅胶二氧化硅进行结束。

The equipment configuration has to diverge to enable the implementation of either approach. Each technique necessitates a variety of polishing machine to grind and polish the sample down to the appropriate surface finish needed for scanning electron microscope examination.

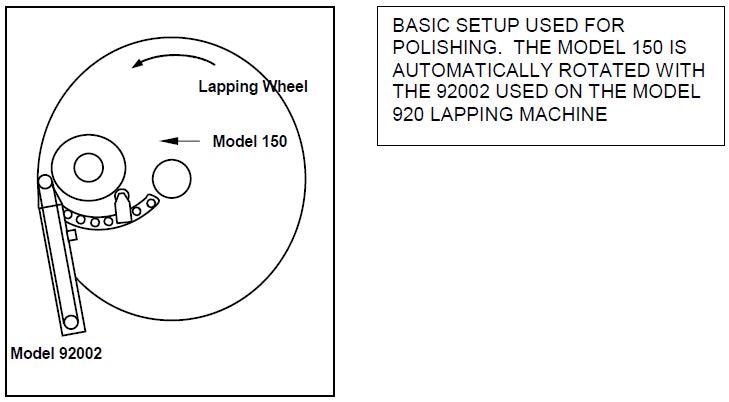

In each case, the samples also require securing with the assistance of a jig or fixture, to guarantee a proper plane of polish and accurate extraction of material. A simple illumination of the mechanism utilized for securing samples onto a polishing machine for processing is exhibited below.

Polishing Machines and Workstations

For encapsulated cross sectioning, theModel 920 Lapping and Polishing Machine,通常使用92002型号工作站合作。借助于150型打式和抛光固定装置,将样品固定和给药,该固定装置在加工过程中被抓住和旋转。图1显示了此系统的图像。

图1。图1显示了持有150型打印和抛光固定装置的基本布置。

For un-encapsulated cross sections, the Model 920 Lapping and Polishing Machine, in collaboration with the Model 595 BiPod Polisher™, is implemented. In certain instances, the Model 92002 Workstation can be engaged to secure the 595 onto the polishing wheel, yielding a semi-automatic system. Figure 2 displays an image of this system.

图2。Figure 2 shows the basic arrangement for holding the Model 595 BiPod Polisher™ onto the Model 920.

This information has been sourced, reviewed and adapted from materials provided by Ted Pella, Inc.

有关此消息来源的更多信息,请访问Ted Pella, Inc.