The growing demand for hydrocarbons is constantly pushing oil and gas producers to locate and produce new downhole reserves, which usually involve aggressive downhole conditions. One such demanding condition involves high pressure, high temperature (HPHT), where the environment reduces the available range of technologies and materials to exploit such deep reservoirs.

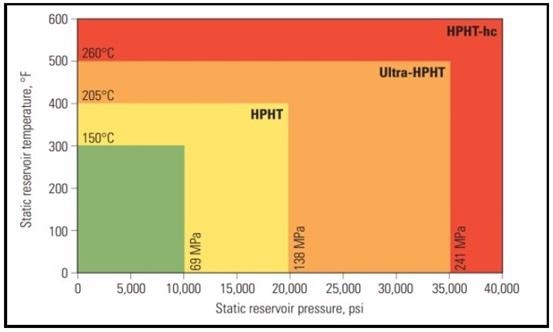

HPHT operations have been divided into three tiers. Tier 2 usually involves wells with fluid pressure of 20,000 psi and temperature up to 400 °F as shown in Figure 1, and many either currently exist or are upcoming projects in the North Sea, the Gulf of Mexico, Africa, South East Asia, the Middle East and China. Today, oil companies are concentrating on solving major challenges faced during the development and production of such fields, and leading equipment manufacturers and service companies are looking into planned technologies to meet such challenges.

图1。HPHT条件(SPE#163376)。

为HPHT构建密封技术挑战应用

为了确保井下井是稳定且持久的,已经强调了可以承受苛刻条件的新塑料材料的研究和开发。亚博网站下载但是,测试HPHT技术的过程是一项复杂且耗时的任务,可能需要数月甚至一年的时间,尤其是在失败的情况下。一项技术以sealing solutions,就安全设备和阀门在升高的温度和压力等级中的可靠性而言,这被强调为主要关注点。在石油和天然气智商(当前的趋势和HPHT操作中最大的挑战)进行的一项调查中,有57,000名专业会员资格被拉入,他们指出密封件是最大的技术差距,其次是测试和安全措施。

在上述HPHT条件下,弹性材料达到其极限,可以吹出或挤压。亚博网站下载弹性体的一种替代方法是热塑性密封溶液,因为它们具有较高的化学和热耐药性,并且没有快速的气体减压行为。为了应对这些新的行业挑战并更好地为客户提供服务,Omniseal Solutions™创建并测试了新型的热塑性材料配方,以在弹簧加密密封设计上进行工程进展。

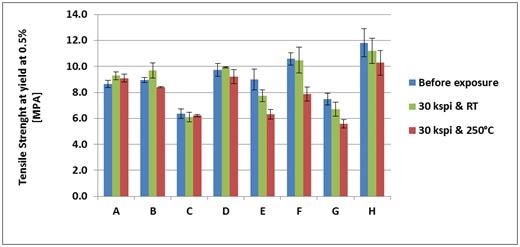

A number of formulations of thermoplastic materials, predominantly PTFE materials (A to H as shown in Figure 2) intended as a seal jacket, have been exposed to isostatic pressure of 30,000 psi at 482 °F (250 °C) and 30,000 psi at room temperature. The main pressure-assisted sealing component is seal jacket, encapsulating a corrosion-resistant metal spring (energizer). Furthermore, the test pressure for most of the surface equipment often employs a safety factor of 1.5 for pressure testing. This is the reason for testing at 30,000 psi. Tests results did not reveal any major changes on the material tensile strength, which suggests that evolution of mechanical properties cannot be predicted on such grades during the seal’s lifespan.

Figure 2.Tensile strength of thermoplastic materials before and after exposure at 30,000 psi.

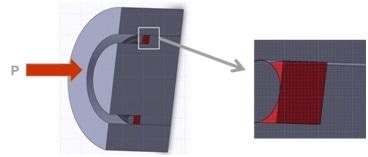

由于备用环通常会在压力和温度升高时阻止密封外套材料挤出,因此开发了另一种测试方案,以评估16个不同等级的备用环材料的行为。亚博网站下载这些组件由不同的配方或与夹克相同的材料制成,因为它们的主要功能不是密封,而是通过挤出间隙抑制材料的流动。如图3所示,该测试方法模拟了各种使用中的挤出条件。系统压力将要测试的材料推入挤压间隙。对于每种材料,在四个小时内在392°F(200°C)下暴露于25,000 psi后确定挤出长度。

Figure 3.挤出测试固定装置。

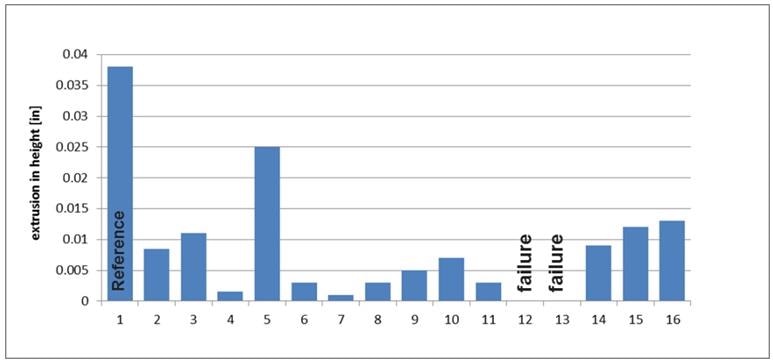

The reference material (material sample 1 shown in Figure 4) demonstrates the largest extrusion of 0.038 inches. Out of the 15 other materials evaluated, 13 showed significant lower extrusion compared to the reference material. During the test, two material samples failed. Among the tested materials, material samples 4 and 7 showed the lowest rate of extrusion and hence were evaluated best candidates for back-up rings materials.

图4。挤压性能of back up ring materials for HPHT applications.

Developing Seal Design and Testing Validation Method

最有前途的弹簧加密密封使用有限元分析(FEA)评估设计配置。这样做是为了防止广泛的经验测试活动。为此,采用了模块化方法来整合夹克和备用环元件的聚合物模型和现有的金属弹簧模型(可商购的)。但是,没有使用市售的聚合物模型,因为它往往不准确地反映了在物理测试时组件的行为。

这就是为什么Omniseal Solutions™引入了广泛的研发计划,以开发自己的热力学模型,以使用用于HPHT应用中的最佳聚合物候选者。对于一系列弹性密封设计,与物理测试相比,FEA模型已被完全验证。该模型使在动态和静态条件下运行模拟参数研究,众多密封夹克材料,多组分设计以及春季类型。亚博网站下载

FEA模型验证了随后在物理测试台上测试的最有前途的设计,Omniseal Solutions™还在内部开发了该设计。图5显示了用于茎密封测试的长凳,从而重现了茎的上升和¼弯曲的茎运动,最高为392°F(200°C)测试温度和30,000 psi测试压力。FEA产生的最有希望的设计通常是在API 6A PR2方案作为初始筛选后测试的。还可以使用API 17D测试协议进行其他测试。

Apart from testing the most promising designs from FEA, a parametric study campaign was also introduced in parallel. The goal of this campaign is to optimize and assess the performance effect of each parameter in a sealing system. Focus is given to hardware parameters (hardness and roughness) and seal design parameters (jacket with spring). The result of the parametric study allows developers to suggest an optimized design that is pre-validated after the API 6A PR2 protocol is extended with the API 17D protocol. The study also advises developers on the best hardware configuration.

图5。HPHT测试杆的测试台。

由于多年的研究和开发工作,Omniseal Solutions™现在可以开发和评估适合HPHT条件的热塑性材料的许多配方。亚博网站下载内部开发的FEA模型能够准确地描述此类材料的热机械性能,从而节省了大量的时间和成本。亚博网站下载然后,使用独特的测试工作台,可以预先验证最有希望的密封系统,以便为客户提供可靠的密封解决方案,以为即将到来的石油和天然气行业中的HPHT项目提供可靠的密封解决方案,并弥合这些挑战性环境所需的技术差距。

This information has been sourced, reviewed and adapted from materials provided by Omniseal Solutions™.

For more information on this source, please visitOmniseal Solutions™。