在本文中,牛津仪器提出了一个使用电子背丝衍射(EBSD)的实验,以表征在原位等级加热期间,弯曲的6063铝合金弯曲板的显微镜区域变化。

已经表明,弯曲过程在跨拉伸区域构成了质地和应变的梯度。在应变梯度驱动的恢复和重结晶之后,这些实验解释了这一点。

TheOxford Instruments Symmetry EBSD detectorwas chosen for this study, as it is capable of handling infrared emissions from heated samples. This detector uses the standard phosphor screen supplied with Oxford Instruments’ EBSD detectors.

实验

2毫米厚的铝板(参见表1以获取表1)垂直于滚动方向。从弯曲中切出样品,然后将其机械地计划至约1.5毫米厚。

然后将铝涂到1μm的钻石上,并使用Struers A2电解液进行电抛光。样品在Fischione 1060 SEM磨坊中用短离子磨坊完成。

表格1。铝合金6063的组成。

| 元素wt% |

毫克 |

铁 |

Si |

Al |

| 6063 |

0.45-0.9 |

0.35 |

0.20-0.6 |

余 |

将样品小心地安装在曼彻斯特大学提供的供暖阶段。该阶段安装在FEGSEM中,其中使用AZTEC®软件使用对称检测器进行成像和EBSD。

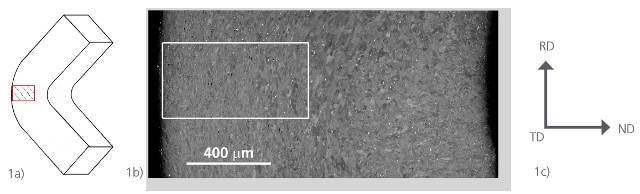

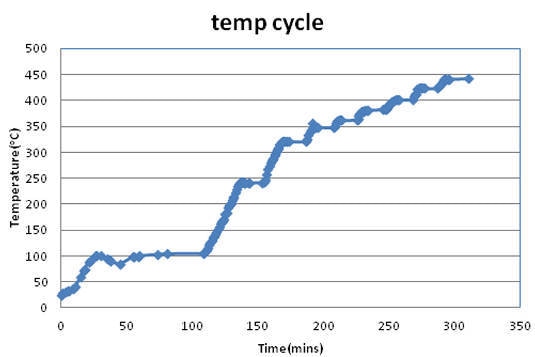

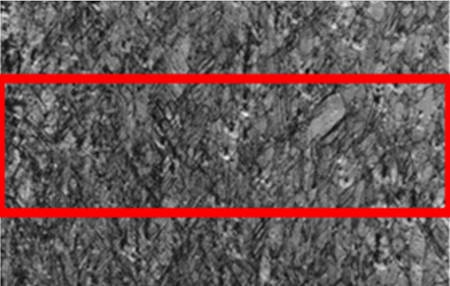

Data was acquired from the tensile region of the bent sample, as shown in the schematic diagram in Figure 1. The isochronal heating cycle is shown in Figure 2. EBSD data was acquired at ambient temperature, 243, 320, 350, 363, 382, 400, 425 and 440 ºC.

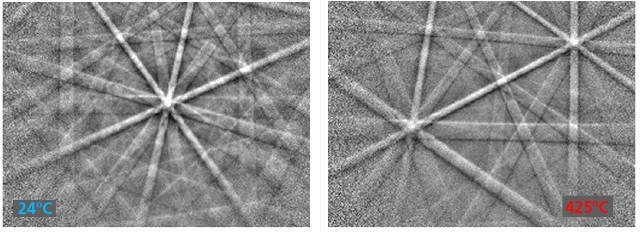

图3A和B分别显示了环境和425ºC时的典型EBSD图案,这表明加热对图案质量的影响很小。

图1. A)Schematic diagram of the bent sampleb)来自图1a的哈希区域的SEM图像。该图像中的矩形区域表明从供暖实验中获取EBSD数据的近似区域,并且c)显示纸的原理轴。

Figure 2.温度周期用于原位加热测试。

结果与讨论

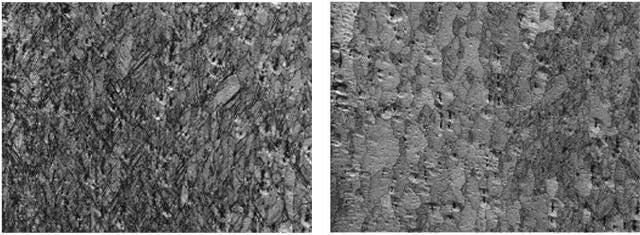

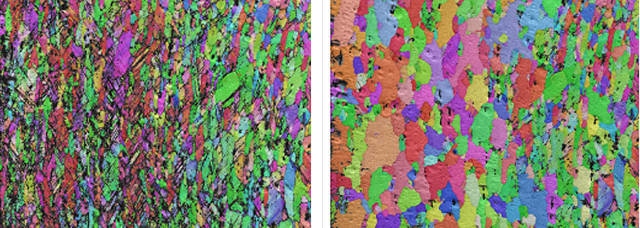

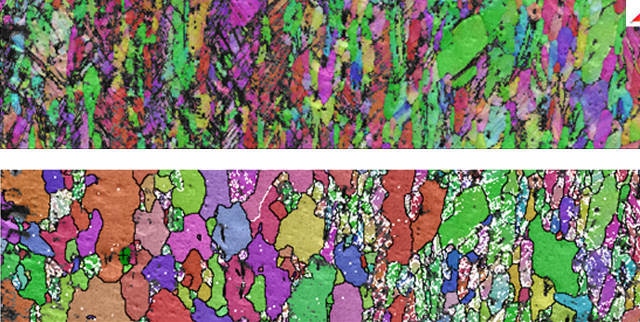

A series of EBSD patterns, as well as IPF coloured and recrystallisation maps before and after heating to 440ºC, are shown in Figures 4-6 respectively. These show that the initial, finer, elongated grains have been replaced with coarse grains.

However, complete recrystallisation has not been realised and many of the recrystallised grains are confined towards the highly strained regions at the sample surface, as expected. Some islands of unrecrystallised grains also persist within the recrystallised/recovered regions.

Figure 3.24ºC(左)和425ºC(右)的典型EBSD图案。

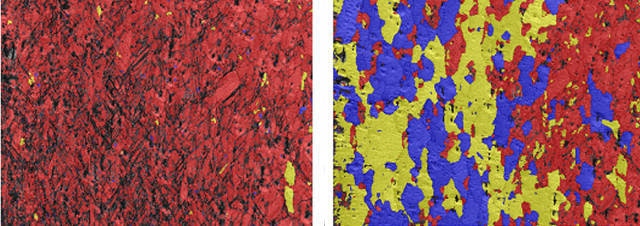

图4。EBSD图案质量地图(左)和(右)加热至440ºC。

图5。EBSD pattern IPF coloured maps before (left) and after (right) heating to 440ºC.

图6。EBSD再结晶分数图(左)和(右)加热后至440ºC。(蓝色=重结晶,黄色=子结构,红色=变形)。

图3-5显示了微观结构的演变,通过从图7中标记的近似区域收集较小的更高分辨率图来研究。

图7。矩形区域显示了收集较高分辨率图的位置,以研究原位加热期间微观结构的演变。

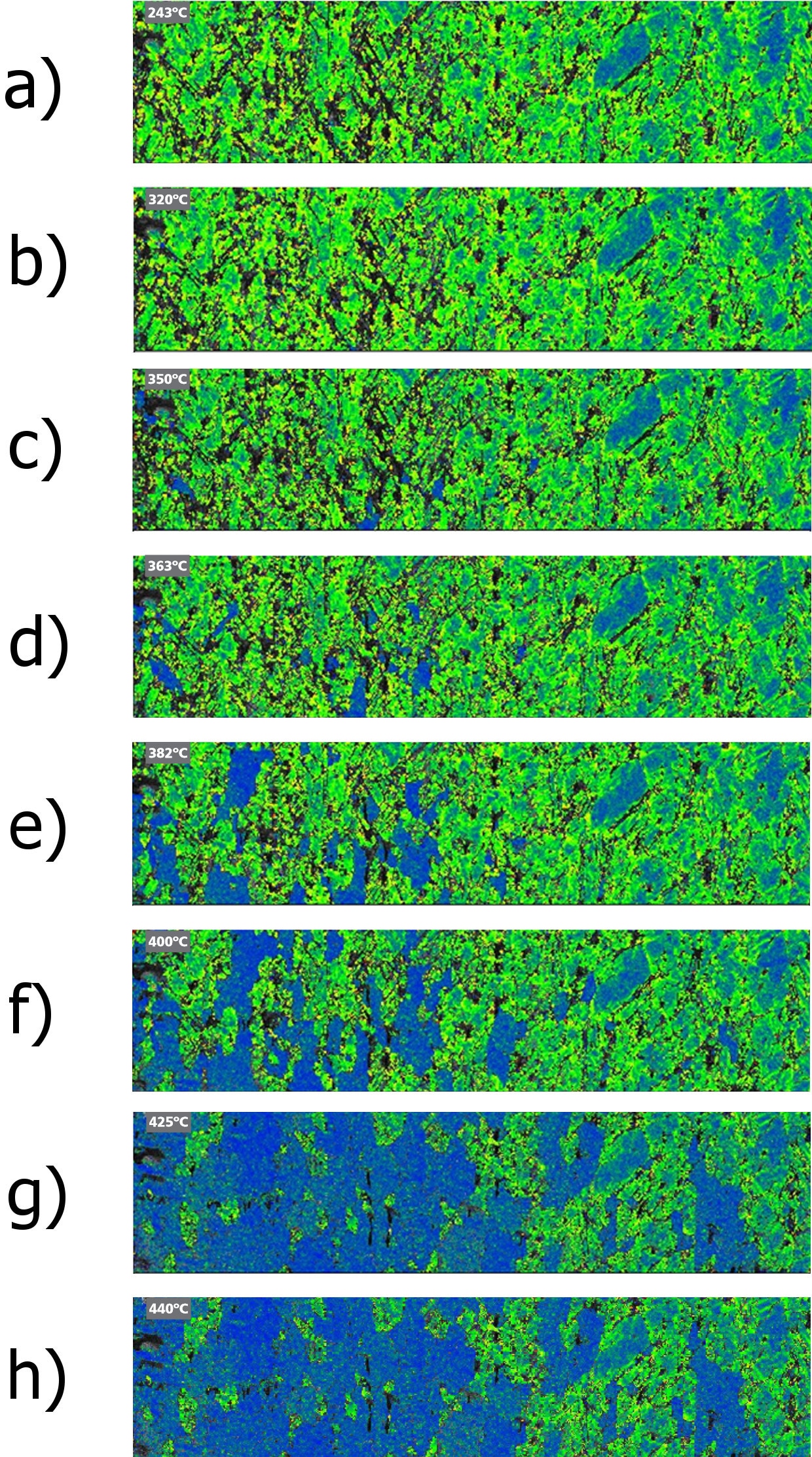

Figures 8 a-g) show EBSD maps of local misorientaion, visualising the progression of recrystallisation during heating.

重结晶的颗粒以蓝色显示,局部不良对象最小。这些图像表明,重结晶颗粒的第一个暗示仅在加热至350ºC后才出现,如图8C所示。

虽然最大的应变区域朝着图像左侧的表面有新的晶粒,但这些谷物也较远。这表明应变分布在某种程度上是异质的,这可能是由于第二相颗粒密度的局部变化。

随着温度的升高,新鲜成核与现有新晶粒的生长同时进行。在滚动方向上,谷物的生长似乎稍快一些。这可能是由于纸张中存在的第二相粒子的固定效应。yabo214

事件of particle simulated nucleation were not observed, as the individual particles are much smaller than the resolution of the maps.

图8. A-H)EBSD图案加热后,IPF彩色地图分别为243、320、350、363、382、400、425和440ºC。

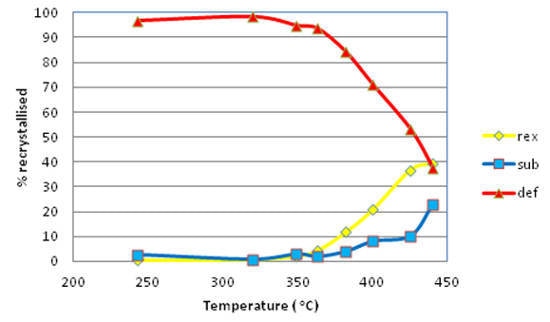

A graphical representation of the recrystallised, sub-structured (recovered) and deformed fraction as it alters with temperature is shown in Figure 9.

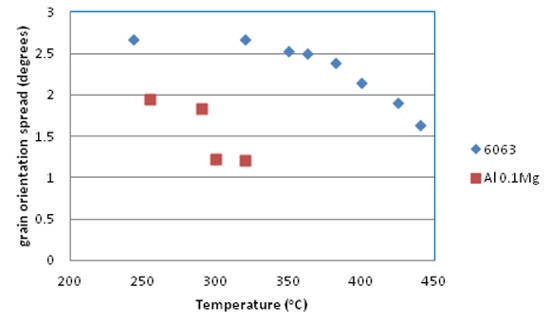

The change in grain orientation spread (GOS) over the heating cycle is shown in Figure 10. This plot also shows data for an Al 0.1 Mg alloy, where it is observed that the reduction in GOS for alloy 6063 is not as rapid as that found in an Al 0.1 Mg alloy.

这再次表明,恢复和重结晶过程受第二相颗粒显着影响。yabo214

图9。重结晶,亚裁定(恢复)和变形的分数与温度的图。

图10。晶粒方向扩散与温度的图。

在高达440ºC后的起始和最终微观结构的比较显示EBSD IPF彩色地图在图11中。图11中的下图还显示了晶界,>2º白色,黑色>8º。从白色的低角度边界可以辨别图10b中的未结晶部分。

These maps clearly illustrate that large grains have replaced groups of fine deformed grains. Because the new grains nucleated in regions that had several differently oriented grains it has not been possible to show clearly if the new grains have any relationship with the deformed grain orientations.

Figure 1.顶部:EBSD IPF彩色启动图和最终微观结构的彩色图分别为440ºC。底部:EBSD IPF地图另外显示了晶界,其中>2º=白色,>8º=黑色。

However, from an initial inspection of the data set it was possible to discern that the first set of grain to nucleate were rotated Goss, Goss, rotated cube and cube, plus some Copper, Brass and S oriented grains. With the increase of temperature the rotated cube grains grew faster than the other orientations.

现有的变形旋转的戈斯或戈斯谷物几乎没有倾向于重结晶,并且抗拒被相邻的重结晶谷物所消耗的倾向。一个示例在图11中标记为A。

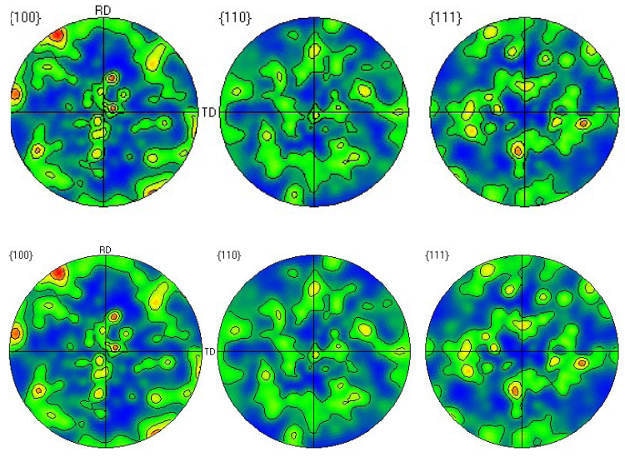

在图12a和B中,将其加热至243ºC和440ºC后显示了轮廓的杆子。这些还表明,旋转立方体组件的强度有所增加。然而,由于接近80%的恢复和变形组件,变形纹理仍然是主导的。

Figure 12.Set of {100}, {110} and {111} EBSD contoured pole figures after heating to 243 and 440ºC respectively.

Conclusions

使用原位加热实验的可行性,同时使用晶体学信息使用牛津仪器的EBSD解决方案已被证明。

已经观察到第二相粒子对缓慢恢复和重结晶过程的影响。已经注意到,在重结晶的早期阶段,戈斯和旋转的戈斯晶粒的倾向及其成核的倾向。

旋转的立方体晶粒成核以及它们较高的生长速率导致在弯曲样品的拉伸区域中形成主要的旋转立方体纹理。

该信息已从牛津仪器纳米分析提供的材料中采购,审查和改编。亚博网站下载

有关此消息来源的更多信息,请访问牛津仪器纳米分析。